Fett_Ish

Sr Member

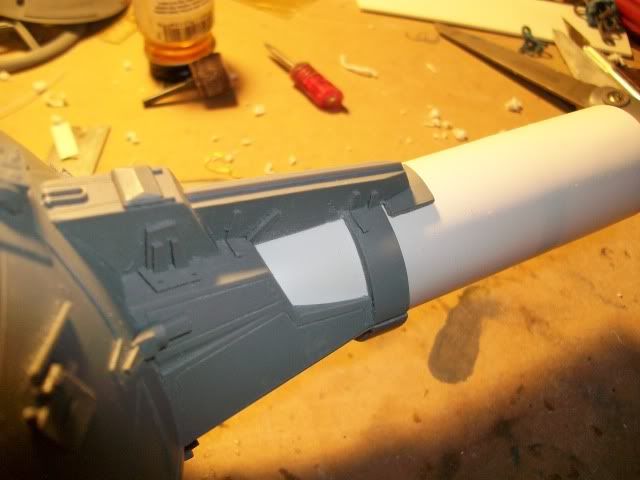

Good call on those outer pieces there. On mine one side is really close and required minor filling, the other had a very large gap. Removing the keys as GF did and sanding them down considerably on the inside would have alleviated this problem. Its looking good DD. Have you decided on colors yet or are you going to custom mix?

Last edited: