ImperialShuttle

Member

Looks great! Great choices on how to finish everything.

How are you guys darkening the pommel section? i tried using aluminum black but it wipes right off??

How are you guys darkening the pommel section? i tried using aluminum black but it wipes right off??

Alley, do u use a brush to brush the aluminum

Black on the booster?

Sent from my iPhone using Tapatalk

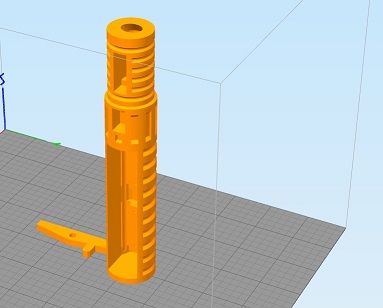

Finally got mine wrapped up...

View attachment 731459

View attachment 731461

View attachment 731462

Since this was an idealized version of the V3, I figured I'd give it an idealized finish. Rather than use aluminum tape, I polished those areas with Mothers Mag & Aluminum Polish.

View attachment 731464 View attachment 731465

For the copper neck, I buffed it with #0000 steel wool, gave it a quick ammonia fuming (only for about 30 minutes) to give it a bit of color in the crevices, and buffed it again.

I also skipped the foil tape on the Graflex clamp, and used a Roman's no logo clamp instead. The finish was already pretty shiny (especially the side bars) but I also polished it a bit with Simichrome Polish. I buffed the clamp rails and the lever with a green Scotchbrite pad to knock the finish down on those. The card is a slothfurnace version 2.0

View attachment 731466

For the black paint I used Krylon flat black and sanded the paint off the ribs with 240 and then 320 grit sanding blocks. I dropped a 5/16" x 3" long bolt down through the neck hole from the inside, tightened it down with a washer and nut on the outside, and chucked it up in a cordless drill. Presto! Poor man's (lazy man's?) lathe. Definitely helped give a nice even finish with the sanding blocks.

View attachment 731467 View attachment 731468

For the remainder of the aluminum I went over all of it with the Scotchbrite pad followed by the steel wool. The face of the emitter got the usual Easy-Off oven cleaner treatment, then a quick wipe with diluted Birchwood Casey aluminum black to dirty it down a bit, followed by some buffing with steel wool. I darkened the interior of the emitter socket with full-strength aluminum black and painted the socket of the copper neck with Krylon flat black.

I had a heck of a time trying to age/darken the clamp/booster section and the pommel cubes. I thought I'd try the dishwasher trick first. No effect. :unsure I washed them a second time. Still nothing. :angry So I started in with the oven cleaner treatment... it went pretty well at first - I was getting them to look kinda' grey , but the tone was uneven. I kept going but it reached a point where it seemed like each application that I put on appeared to be cleaning off the grey finish that I had built up - it was weird. :confused On a whim I thought I'd try the dishwasher again. Disaster! The uneven oxidation from the oven cleaner treatment darkened into big blotches - it was like some sort of strange camouflage. So I stripped them back down to bare aluminum with the Scotchbrite and steel wool.

I saw in another thread that someone had used drain cleaner on a V2, so I thought I'd give that a try. I did the pommel first, soaking it in a shallow dish, and it worked rather well (and quickly). But as I was rinsing it off I started rubbing it and the oxidation layer came right off. Poop.Back to the oven cleaner...

As I was doing the oven cleaner treatment again I kept thinking about the drain cleaner. I tried the drain cleaner again, but when I rinsed the part off I didn't touch it. I let it dry overnight and that was the trick. :thumbsup I gave the pommel another quick soak and then did the clamp/booster section, but I got them both way too dark. Stripped 'em back down to bare aluminum and tried again. Again too dark, so after a couple more tries I got them to where they are now, which I'm OK with. The drain cleaner works fast - a minute and a half to two minutes is all it took.

View attachment 731469

Overall I'm pretty happy with it. Thanks for the fun project Rudy!

Question: Where are you guys getting your tape to cover the clamp? Are you suing autoshop tape? They all look amazing!

I got some tape! I am also experimenting with a Wannawanga's clamp cover with matching punched holes, but I'm having trouble mounting it on the clamp....

View attachment 733860

I'm using Birchwood Casey Aluminum Black diluted in a lot of water. You can get it from Amazon. I used about 1/3 of the bottle for that container of water. I got the container from IKEA.D4r7hur, which product and brand did you use to get this result?

Envoyé de mon SM-T800 en utilisant Tapatalk