Ever since I saw the box art from the original Fallout game, I've been resisting the ongoing urge to build a set of power armor. With the release of the trailer for Fallout 4, the new design is finally awesome enough that I can't help myself any longer.

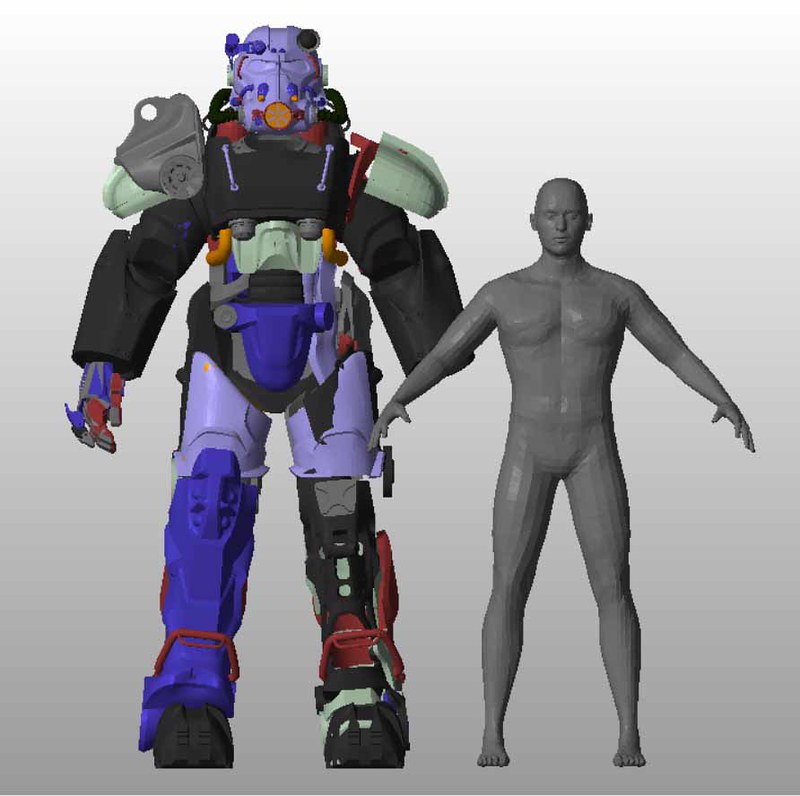

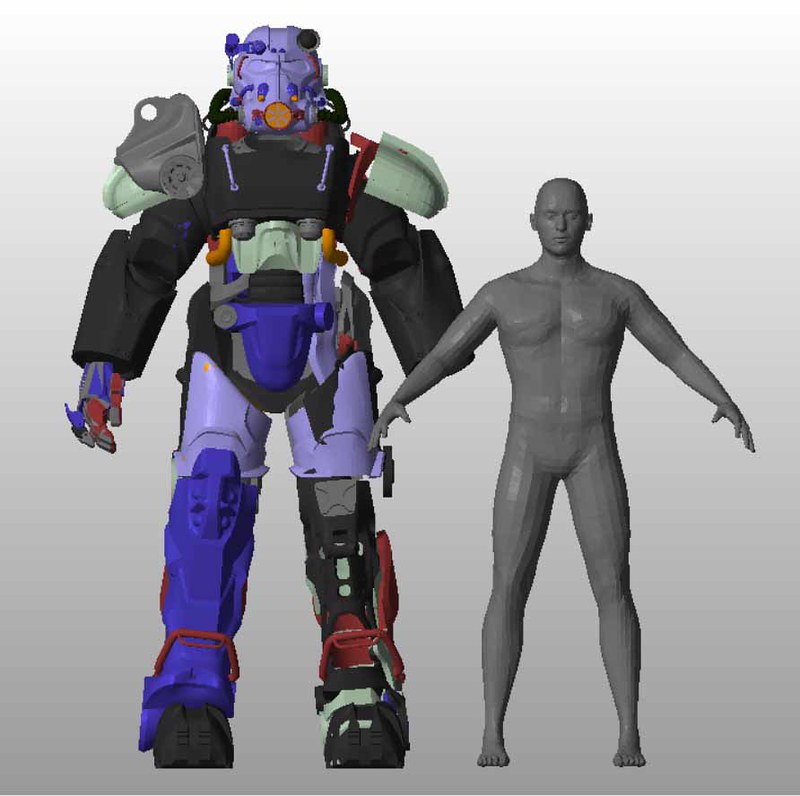

So I partnered up with a 3D modelling friend of mine named Joost (check out www.facebook.com/prodofdes for some of his other work) and he took the in-game models and smoothed them out a bit to make something I could actually justify using in my CNC machines and 3D printers. Here's the first renders he sent me:

So I started going through the tedious process of making sure the pieces were all completely watertight and CNC or print ready while establishing a scale:

The gray dude to the right in the pic above is set up with proportions similar to my 5'7" frame.

Once I was satisfied that the whole thing was going to be suitably massive, I set to work slicing up the bigger pieces so that they could be carved out. If you've followed my builds before, you may be familiar with Lopez the Robot Whittler, my Carvewright CNC machine. But what you might have missed is that I've picked up more of them. Now I've also got Lopez Dos Point Oh, Maria the robot, and and as yet unnamed fourth Carvewright. By running at least two of them at a time, I figured I'd be able to crank out big parts for this build pretty quickly.

For example, here's all of the slices for the helmet carved out of 3/4" MDF:

From left to right, those each took 6, 7, and 8 hours of carving time for one machine. By running three machines, they were done simultaneously and at the end of the first day of physical work on this project, I popped all of the waste off of the parts:

A few minutes later, the main body of the helmet was assembled:

Smaller detail bits were 3D printed on my Zortrax M200 and added onto the assembled helmet:

The next step is a bunch of filler and sanding and associated bodyshop work:

While I was tinkering with that I had the Zortrax twins (I have two, they're named "Johnny Five" and "Seven of Nine" since I now have nine workshop robots) print out the rest of the helmet greeblies:

At that point I ended up getting distracted with real work and this project was boxed and put on the backburner where it collected dust for a while:

On rare occasion, the backburner is where projects go to die. Most of the time though, they're just lying dormant. Staring silently over the goings-on in the workshop. Taunting my with their ever-present unfinished-ness. When I finally get a gap in my project schedule, I'm thrilled to have a chance to exorcise these demons, blow off the dust, and breathe life back into these creations.

So over the past few months, whenever I don't have any work lined up for the robots, I have them carve armor parts while I focus on other projects. Before too long, the stack of power armor parts in progress was getting respectable:

Every once in a while I'd get sick of the stacks of these carved planks sitting around and I'd snap off all of the pieces and start gluing up parts:

Assembled rough parts have started piling up:

Occasional test fitting revealed that the parts were adequately HUGE:

HUGE:

Seriously. Huge:

Still, while I've occasionally found a few minutes here and there to goof around with this project, until I came up with a notional deadline, the whole thing hasn't gotten much serious effort:

Now I've got the Bay Area Maker Faire coming up in late May (details here: http://makerfaire.com/bay-area/) and I usually tend to set up a pretty large display of my various built projects:

I usually like to debut something big and new every year and, since I missed last year, I'm really looking forward to being able to show off something new this year. So guess that's as good a reason as any to kick this build into high gear and make something happen.

So I've been doing a lot of cleanup and prep work on the prototype parts lately. I've also designated one of the girls in my shop to do nothing but sand all of the pieces smooth whenever she's around:

Which means things are really starting to take shape:

At this point I've already started making molds for some of the smaller armor pieces. Most of the larger parts still need a bit more bodyshop work:

Construction will be primarily fiberglass parts built around an ALICE pack frame and a pair of drywall stilts to make this beast functionally wearable. Time permitting, I'll even work in articulated hands and hopefully put together a few videos about the build so I can talk through the making of fiberglass molds, silicone molds, stone molds, rubber parts, and so on.

Done right, this thing will be awesome:

Stay tuned...

So I partnered up with a 3D modelling friend of mine named Joost (check out www.facebook.com/prodofdes for some of his other work) and he took the in-game models and smoothed them out a bit to make something I could actually justify using in my CNC machines and 3D printers. Here's the first renders he sent me:

So I started going through the tedious process of making sure the pieces were all completely watertight and CNC or print ready while establishing a scale:

The gray dude to the right in the pic above is set up with proportions similar to my 5'7" frame.

Once I was satisfied that the whole thing was going to be suitably massive, I set to work slicing up the bigger pieces so that they could be carved out. If you've followed my builds before, you may be familiar with Lopez the Robot Whittler, my Carvewright CNC machine. But what you might have missed is that I've picked up more of them. Now I've also got Lopez Dos Point Oh, Maria the robot, and and as yet unnamed fourth Carvewright. By running at least two of them at a time, I figured I'd be able to crank out big parts for this build pretty quickly.

For example, here's all of the slices for the helmet carved out of 3/4" MDF:

From left to right, those each took 6, 7, and 8 hours of carving time for one machine. By running three machines, they were done simultaneously and at the end of the first day of physical work on this project, I popped all of the waste off of the parts:

A few minutes later, the main body of the helmet was assembled:

Smaller detail bits were 3D printed on my Zortrax M200 and added onto the assembled helmet:

The next step is a bunch of filler and sanding and associated bodyshop work:

While I was tinkering with that I had the Zortrax twins (I have two, they're named "Johnny Five" and "Seven of Nine" since I now have nine workshop robots) print out the rest of the helmet greeblies:

At that point I ended up getting distracted with real work and this project was boxed and put on the backburner where it collected dust for a while:

On rare occasion, the backburner is where projects go to die. Most of the time though, they're just lying dormant. Staring silently over the goings-on in the workshop. Taunting my with their ever-present unfinished-ness. When I finally get a gap in my project schedule, I'm thrilled to have a chance to exorcise these demons, blow off the dust, and breathe life back into these creations.

So over the past few months, whenever I don't have any work lined up for the robots, I have them carve armor parts while I focus on other projects. Before too long, the stack of power armor parts in progress was getting respectable:

Every once in a while I'd get sick of the stacks of these carved planks sitting around and I'd snap off all of the pieces and start gluing up parts:

Assembled rough parts have started piling up:

Occasional test fitting revealed that the parts were adequately HUGE:

HUGE:

Seriously. Huge:

Still, while I've occasionally found a few minutes here and there to goof around with this project, until I came up with a notional deadline, the whole thing hasn't gotten much serious effort:

Now I've got the Bay Area Maker Faire coming up in late May (details here: http://makerfaire.com/bay-area/) and I usually tend to set up a pretty large display of my various built projects:

I usually like to debut something big and new every year and, since I missed last year, I'm really looking forward to being able to show off something new this year. So guess that's as good a reason as any to kick this build into high gear and make something happen.

So I've been doing a lot of cleanup and prep work on the prototype parts lately. I've also designated one of the girls in my shop to do nothing but sand all of the pieces smooth whenever she's around:

Which means things are really starting to take shape:

At this point I've already started making molds for some of the smaller armor pieces. Most of the larger parts still need a bit more bodyshop work:

Construction will be primarily fiberglass parts built around an ALICE pack frame and a pair of drywall stilts to make this beast functionally wearable. Time permitting, I'll even work in articulated hands and hopefully put together a few videos about the build so I can talk through the making of fiberglass molds, silicone molds, stone molds, rubber parts, and so on.

Done right, this thing will be awesome:

Stay tuned...