Having been an RPF member for some years it occurred to me I've never posted a build thread here. With that in mind I thought I'd share a build I've got going on GBFans here too  It's a copy and paste so if anything is unclear I can explain my GBfans references if they don't make sense.

It's a copy and paste so if anything is unclear I can explain my GBfans references if they don't make sense.

I love Ghostbusters and always wanted to get all the busting-gear but I thought it best to start small and work up, so I decided to build a trap first. I chose the excellent Nick-a-Tron V2 kit as the basis for my build.

I want to do something different to a straight build by incorporating the cartridge release mechanism as used on the GB1 hero prop, which as far as I know hasn't been tried on a resin trap kit before- making this build a kind of semi-hero in a similar vein to the GB2 proton packs. I'll also be fitting a hyperdyne servo and light kit.

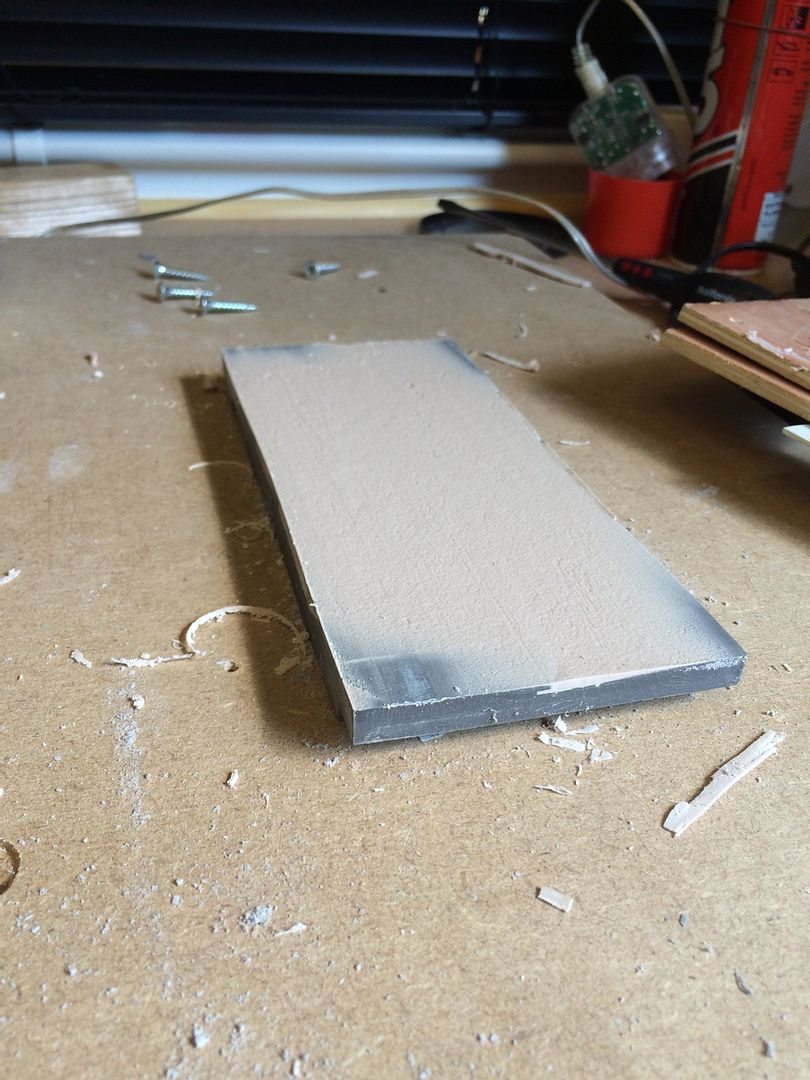

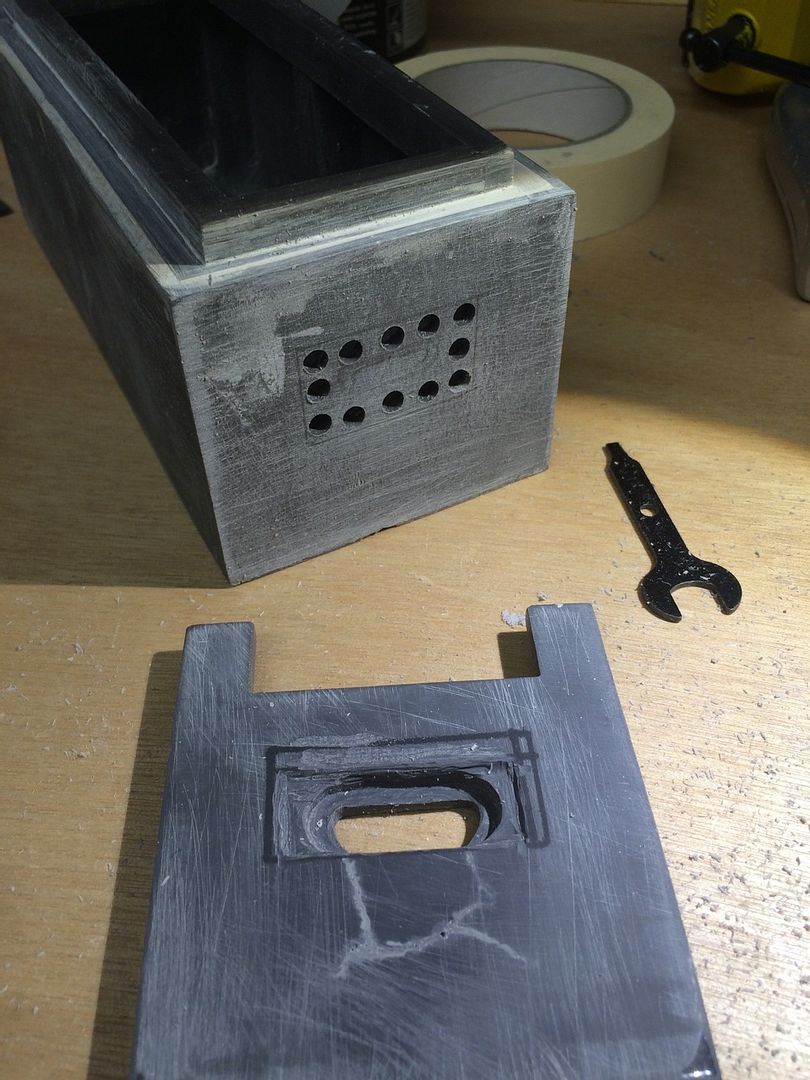

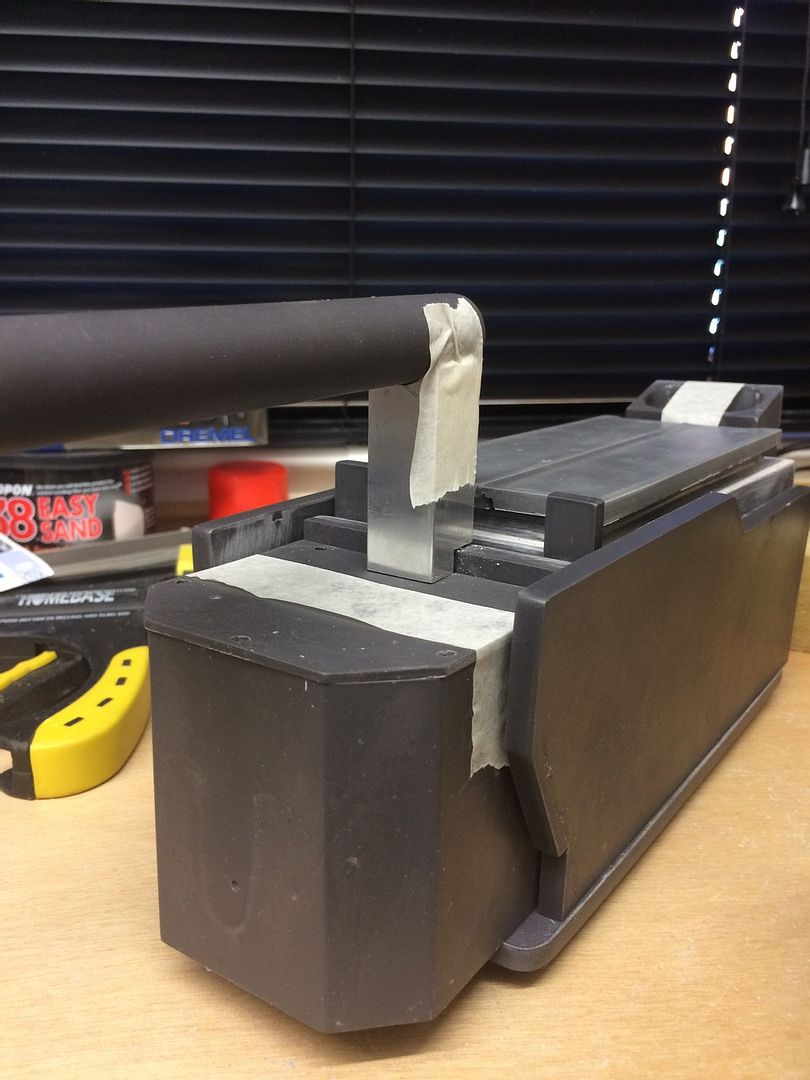

The first thing I plan to do is install a track system like the GB1 hero has. The problem is the base of the nick-a-tron kit needs to be cut down to allow for the extra depth... oh well here goes!

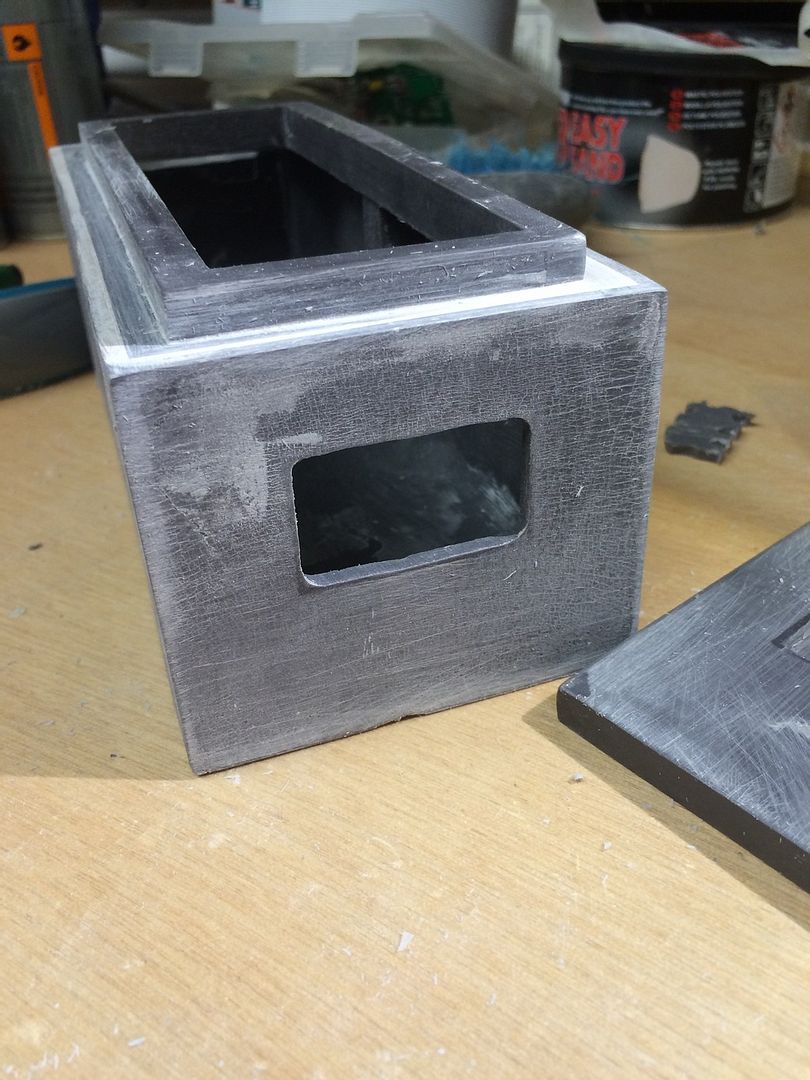

A bit of P38 filler to fix the odd hiccup from the cutting down process!

Not too bad once sanded down

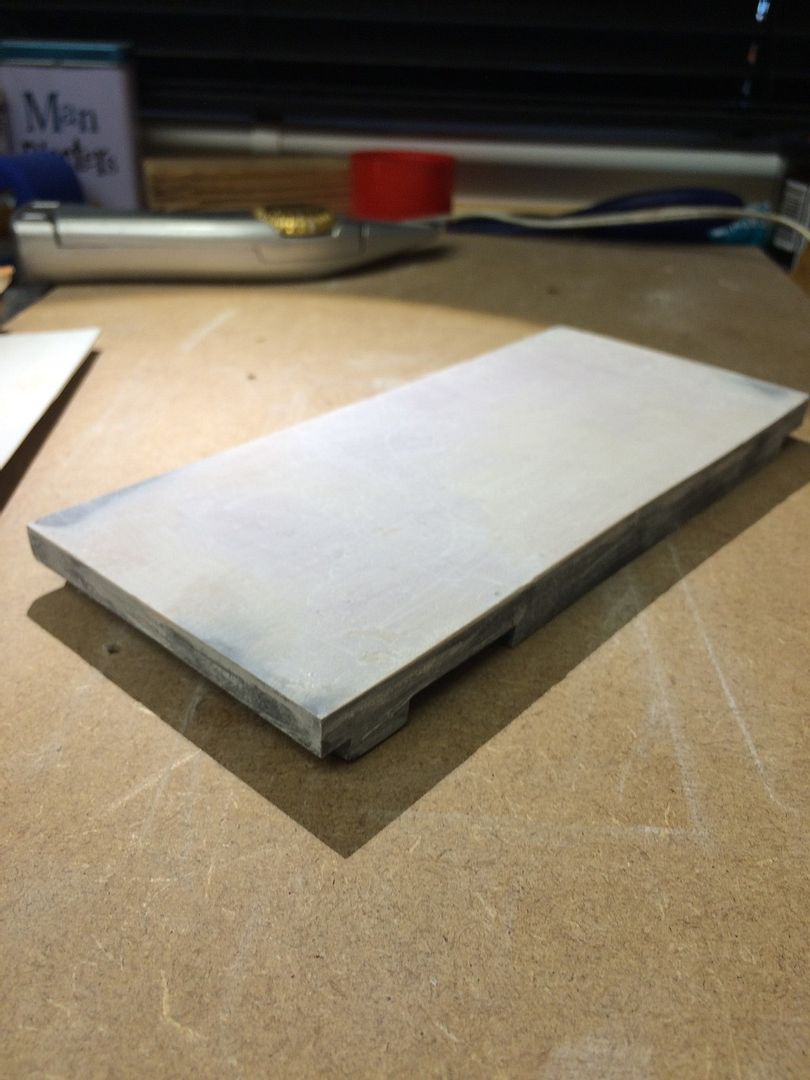

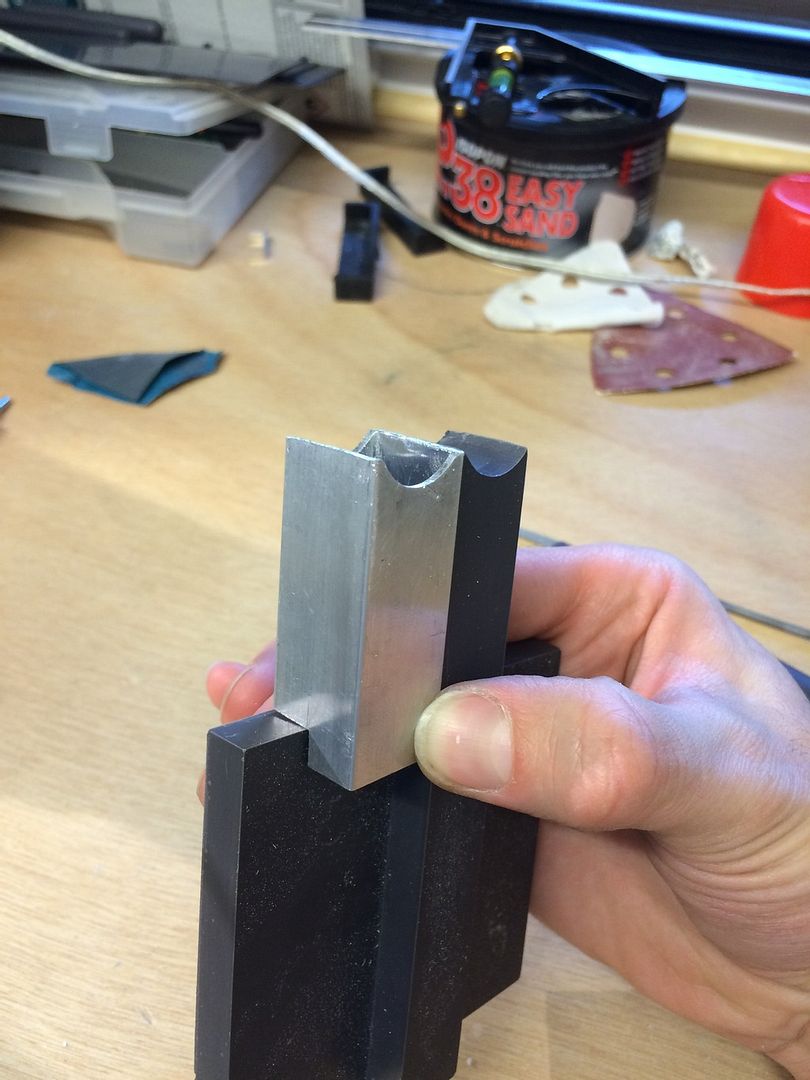

Cut the track from aluminium strips. Only sizes I could find but hopefully a close enough approximation. Then a trial fit together to see how she looks!

The top of the cartridge was then glued in place with epoxy resin, then once that was set solid I filled the gaps around the seam with P38 car body filler leaving me with this:

As this is going to be a hero trap I need to think about cable routing as I assemble the kit. I started by marking out where the front indicator block will go, and from that where to cut a slot for the bargraph cabling

Then it was onto the indicator block itself. I drilled through at the angle I wanted

Then opened it up with the Dremel

I think that should do the trick

Now onto the rear of the cartridge to open up space for the D-sub connector.

I've decided to try to include as many of the little details from the Propbay Hero pictures as I can, in this case namely the side plate fixing bolts.

I noticed in the propbay images that there are five screws running along the bottom of each side plate, countersunk VERY close to the edge.

They're not that visible, but as i'm doing a hero build I thought they should be present. It was a bit daunting but i've drilled as near to the edge of each plate as I dared and i'm quite pleased with how it turned out.

I've also added the screw above the metal side plates. It's not in 100% accurate position fore/aft due to differences in proportion between the real prop and the trap kit but I think I have the height about right

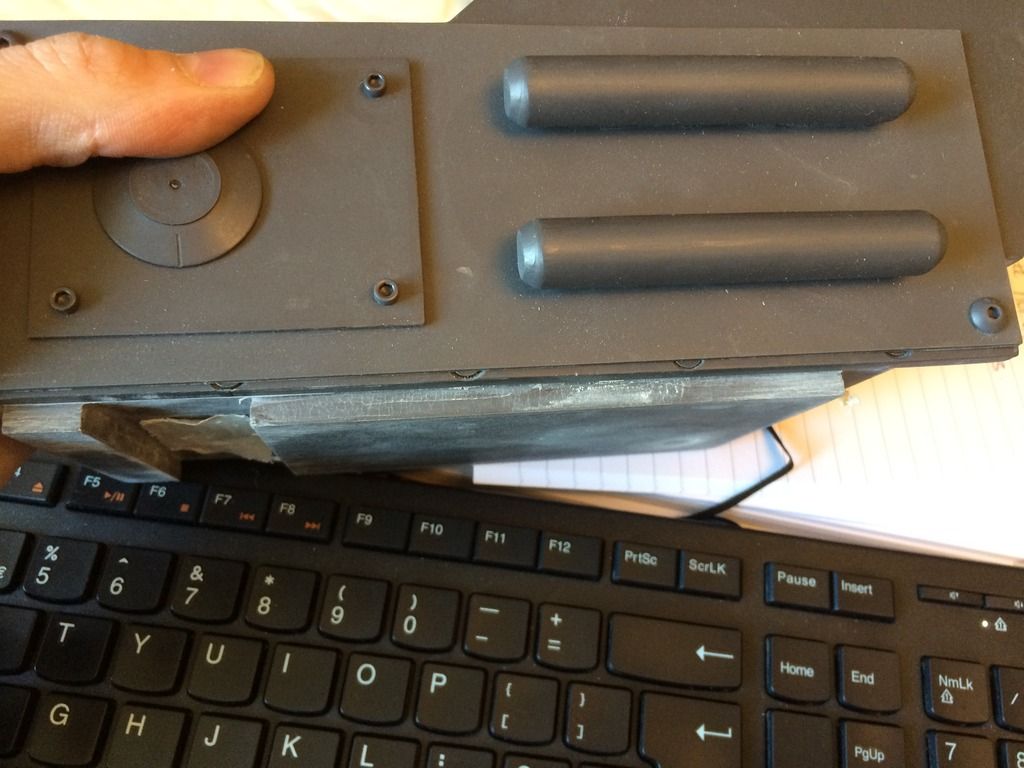

Time to bolt down the tracks. I think there's too much of a gap between the front of the trap and the rails. Measure twice...

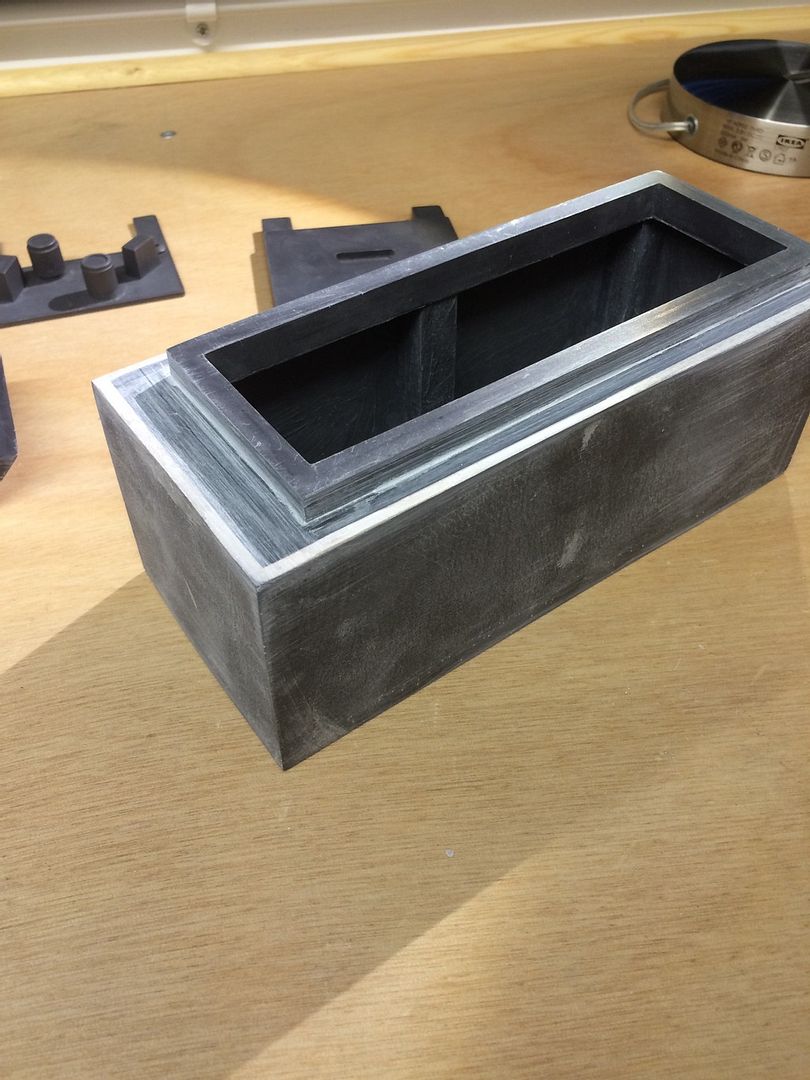

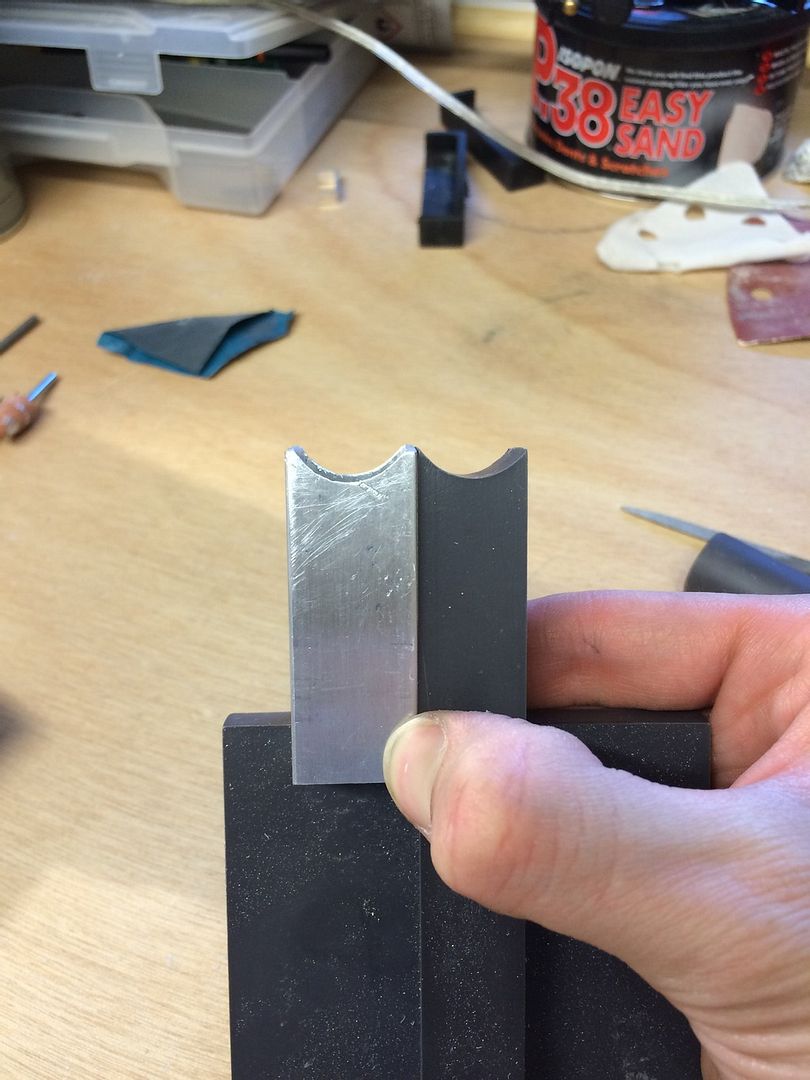

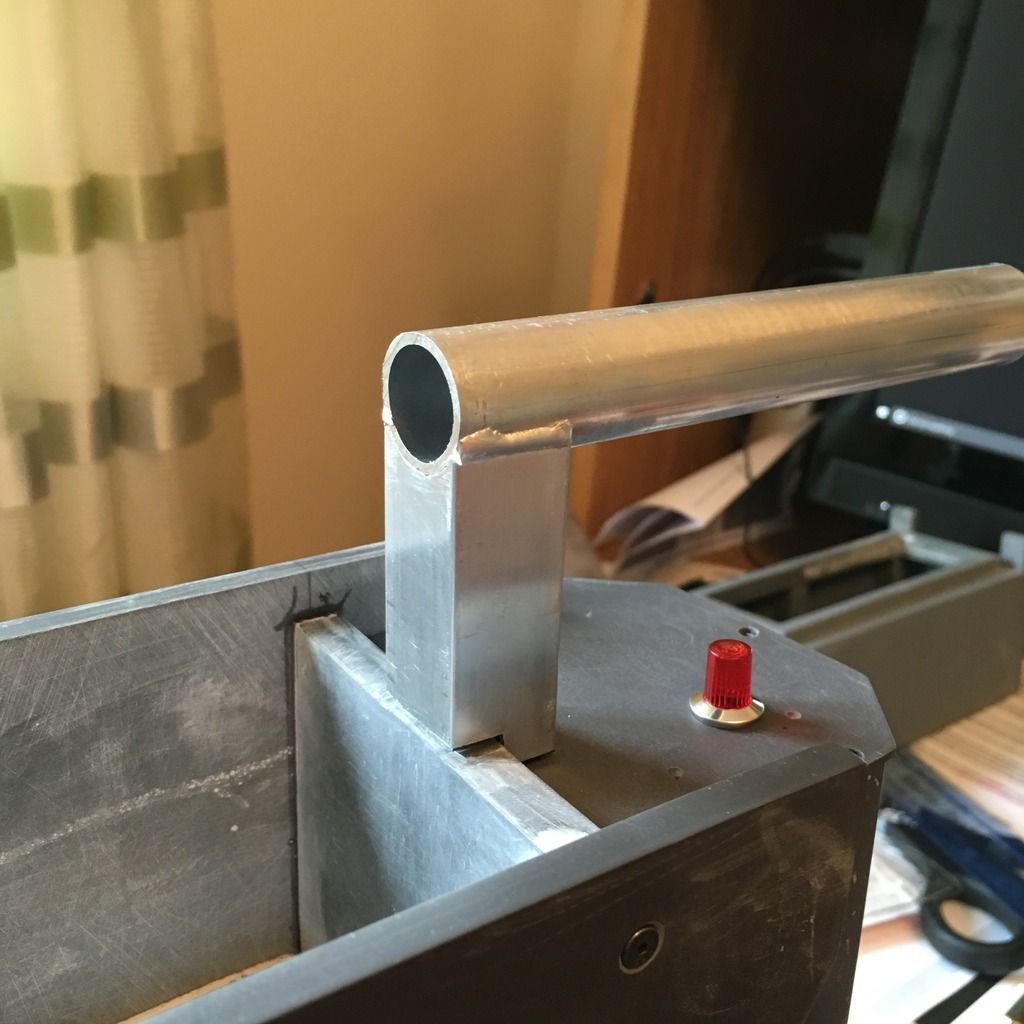

In order to fit the release mechanism for the cartridge the resin handle post on the nick-a-tron kit needs to be replaced, as I felt it would be too weak to support the weight of the trap with the metal tracks fitted if I cut a slot in it. I wanted an aluminium one but money is a bit tight so I thought i'd try to make my own!

I started with a piece of aluminium box section and copied the curve from the resin handle post onto it, then chain-drilled the shape out.

Then I ground it out smooth with a dremel

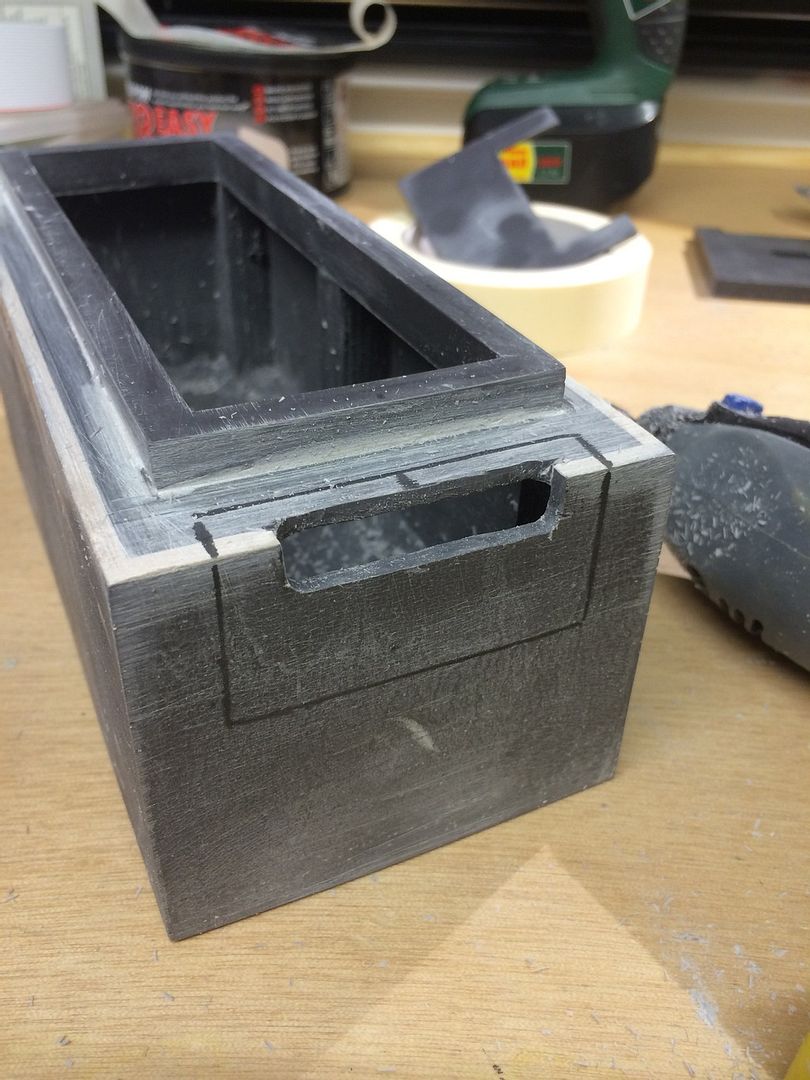

My plan was to epoxy the resin handle in place and simply drill through it to put the release catch in but...

I soon realised that it would be difficult to drill out the resin for the return spring which would be needed to operate the catch. I decided to make an aluminium one to replace it. As I can't weld I was going to epoxy it in place but I was worried about the strength of the handle with the heavy weight of the trap. My brother came to the rescue with a bright idea- as neither of us can weld he suggested an alloy repair product which can be "welded" with only a propane torch.

Here's the result:

I love Ghostbusters and always wanted to get all the busting-gear but I thought it best to start small and work up, so I decided to build a trap first. I chose the excellent Nick-a-Tron V2 kit as the basis for my build.

I want to do something different to a straight build by incorporating the cartridge release mechanism as used on the GB1 hero prop, which as far as I know hasn't been tried on a resin trap kit before- making this build a kind of semi-hero in a similar vein to the GB2 proton packs. I'll also be fitting a hyperdyne servo and light kit.

The first thing I plan to do is install a track system like the GB1 hero has. The problem is the base of the nick-a-tron kit needs to be cut down to allow for the extra depth... oh well here goes!

A bit of P38 filler to fix the odd hiccup from the cutting down process!

Not too bad once sanded down

Cut the track from aluminium strips. Only sizes I could find but hopefully a close enough approximation. Then a trial fit together to see how she looks!

The top of the cartridge was then glued in place with epoxy resin, then once that was set solid I filled the gaps around the seam with P38 car body filler leaving me with this:

As this is going to be a hero trap I need to think about cable routing as I assemble the kit. I started by marking out where the front indicator block will go, and from that where to cut a slot for the bargraph cabling

Then it was onto the indicator block itself. I drilled through at the angle I wanted

Then opened it up with the Dremel

I think that should do the trick

Now onto the rear of the cartridge to open up space for the D-sub connector.

I've decided to try to include as many of the little details from the Propbay Hero pictures as I can, in this case namely the side plate fixing bolts.

I noticed in the propbay images that there are five screws running along the bottom of each side plate, countersunk VERY close to the edge.

They're not that visible, but as i'm doing a hero build I thought they should be present. It was a bit daunting but i've drilled as near to the edge of each plate as I dared and i'm quite pleased with how it turned out.

I've also added the screw above the metal side plates. It's not in 100% accurate position fore/aft due to differences in proportion between the real prop and the trap kit but I think I have the height about right

Time to bolt down the tracks. I think there's too much of a gap between the front of the trap and the rails. Measure twice...

In order to fit the release mechanism for the cartridge the resin handle post on the nick-a-tron kit needs to be replaced, as I felt it would be too weak to support the weight of the trap with the metal tracks fitted if I cut a slot in it. I wanted an aluminium one but money is a bit tight so I thought i'd try to make my own!

I started with a piece of aluminium box section and copied the curve from the resin handle post onto it, then chain-drilled the shape out.

Then I ground it out smooth with a dremel

My plan was to epoxy the resin handle in place and simply drill through it to put the release catch in but...

I soon realised that it would be difficult to drill out the resin for the return spring which would be needed to operate the catch. I decided to make an aluminium one to replace it. As I can't weld I was going to epoxy it in place but I was worried about the strength of the handle with the heavy weight of the trap. My brother came to the rescue with a bright idea- as neither of us can weld he suggested an alloy repair product which can be "welded" with only a propane torch.

Here's the result:

Last edited: