You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scratchbuilt Millennium Falcon 1/72nd

- Thread starter Archive&Future

- Start date

Archive&Future

Sr Member

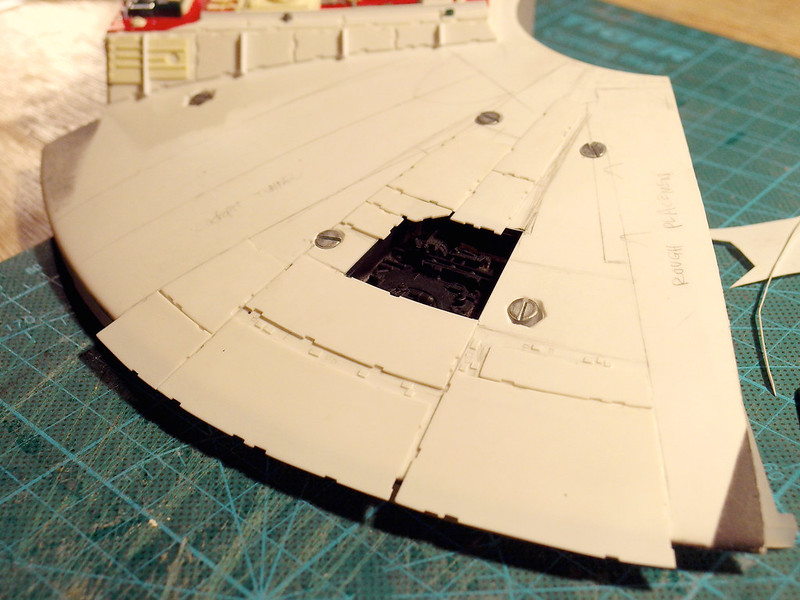

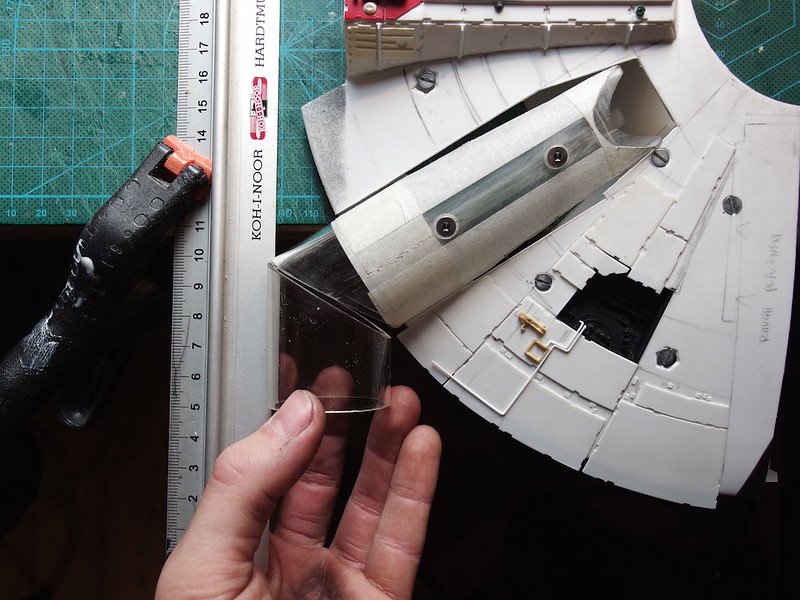

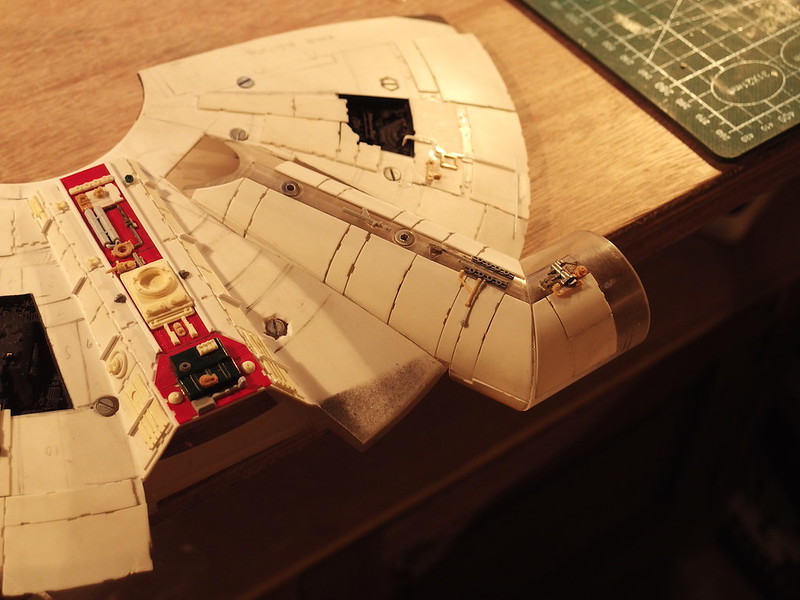

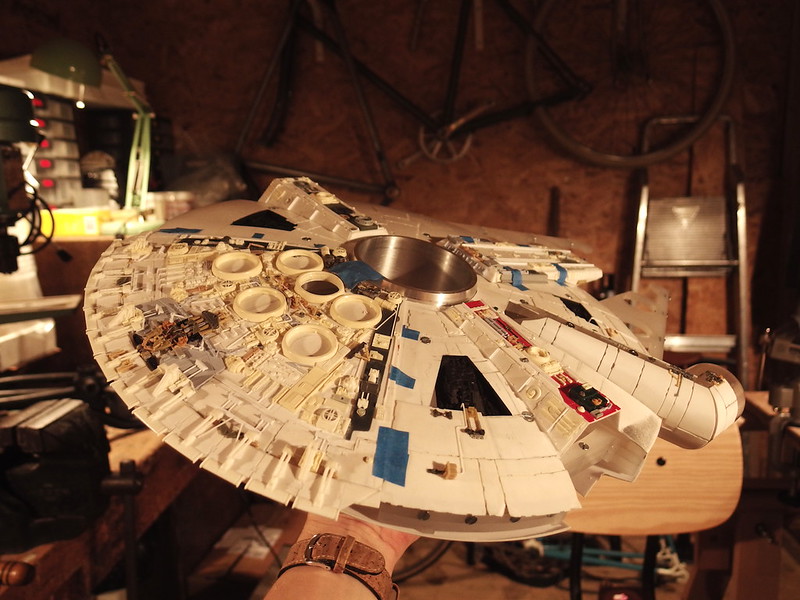

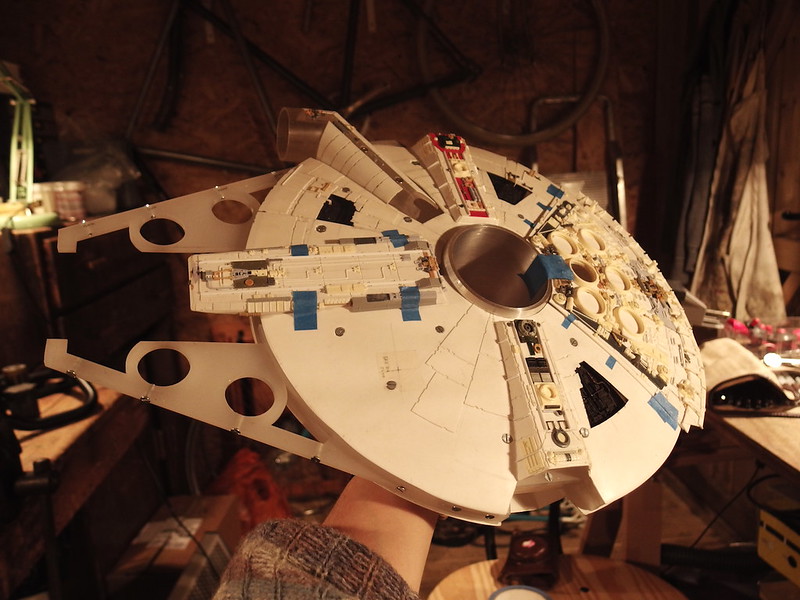

All 26 actuators and aileron panels are now cast and fitted to the engine deck (with double that again cast in preparation for the lower hull)

This afternoon I did a little more work on the armour plating, tedious but the results are rewarding

White balance is a little iffy but you get the idea

This afternoon I did a little more work on the armour plating, tedious but the results are rewarding

White balance is a little iffy but you get the idea

You, Sir... Amazing!

Archive&Future

Sr Member

As always fellas, cheers to your encouragement!

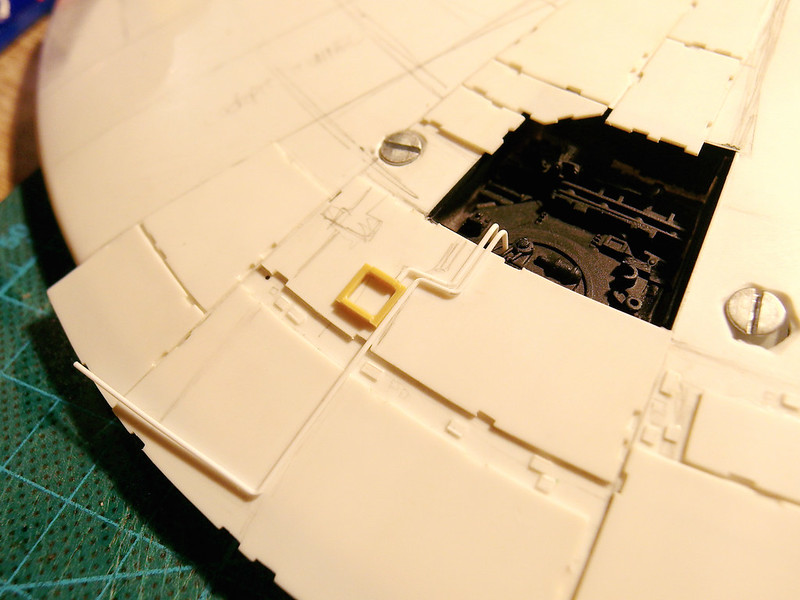

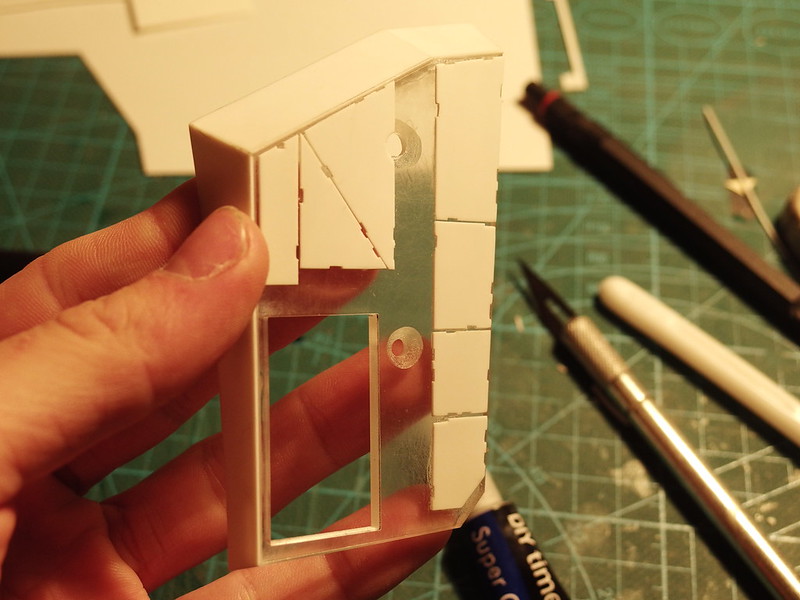

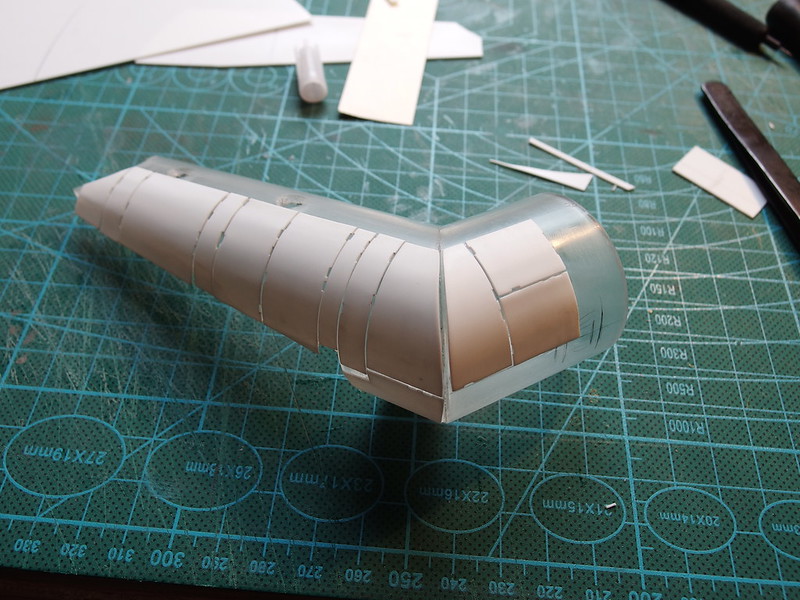

Panelling, despite being visually less complex than dense engine detail, is far more laborious; everything has to fit correctly or it looks off.....quite a few panels were remade twice before I was satisfied.

The crumpling effect I achieved with a lighter and a pair of blunted snips, I would've preferred to use brass shim but I wasn't content with the strength of a CA brass-to-styrene joint

Panelling, despite being visually less complex than dense engine detail, is far more laborious; everything has to fit correctly or it looks off.....quite a few panels were remade twice before I was satisfied.

The crumpling effect I achieved with a lighter and a pair of blunted snips, I would've preferred to use brass shim but I wasn't content with the strength of a CA brass-to-styrene joint

tek2graphics

Sr Member

A+ :thumbsup Beautiful work as always!

Archive&Future

Sr Member

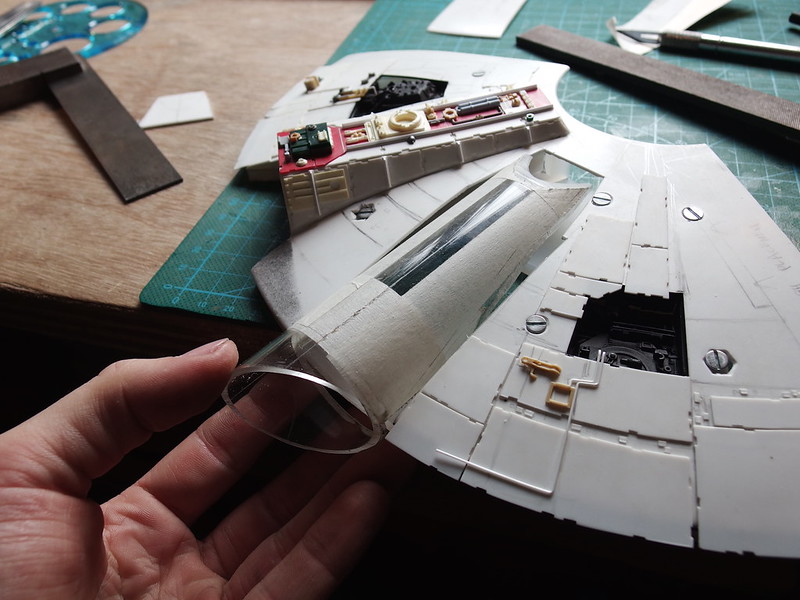

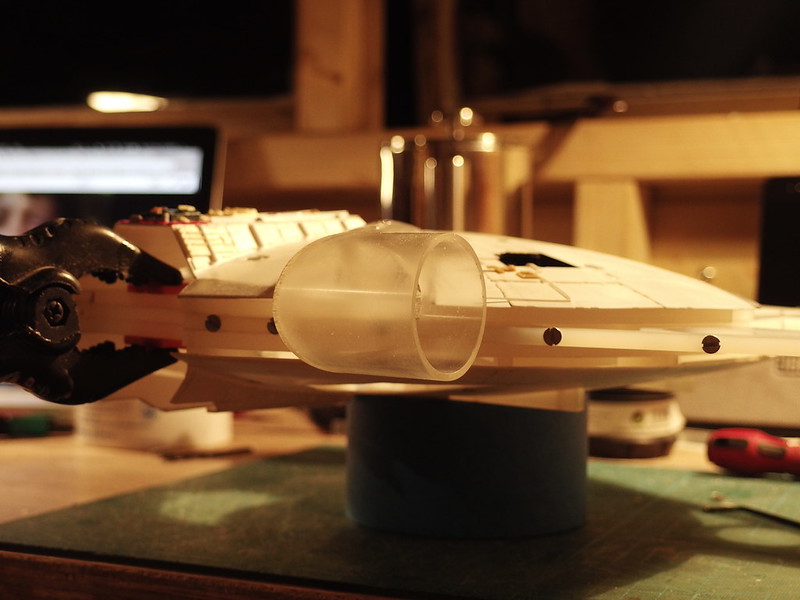

For the past couple of evenings I've been attempting the cockpit tunnel...I spent probably near to an hour solely working out the angles and carefully cutting 40mm acrylic tube to shape.

61º is what my measurements indicate but I don't know if that's necessarily correct.

Now here's where I really need help from you fellow Falcon experts....is the cockpit tunnel level, or is it slightly angled (in the same way that the docking corridors are slightly angled downwards)

And that entails more questions....to anybody out there who's built a Falcon or at least a cockpit tunnel, how did you go about doing it? It's totally stumping me.....

61º is what my measurements indicate but I don't know if that's necessarily correct.

Now here's where I really need help from you fellow Falcon experts....is the cockpit tunnel level, or is it slightly angled (in the same way that the docking corridors are slightly angled downwards)

And that entails more questions....to anybody out there who's built a Falcon or at least a cockpit tunnel, how did you go about doing it? It's totally stumping me.....

Jaitea

Master Member

To Maruska you must listen:

View attachment ANH_MF_FRONT_002.jpgView attachment ANH_MF_TOP_002.jpgView attachment ANH_MF_SIDEPORT_002.jpg

J

View attachment ANH_MF_FRONT_002.jpgView attachment ANH_MF_TOP_002.jpgView attachment ANH_MF_SIDEPORT_002.jpg

J

astroboy

Master Member

Do those exist in .dwg files???? I would love to tinker with them in cad.

Sent from my SM-N910W8 using Tapatalk

Jaitea

Master Member

Do those exist in .dwg files???? I would love to tinker with them in cad.

Sent from my SM-N910W8 using Tapatalk

Join up on Grabcad.....Maruska has made a lot (in not all) of his files freely available......(thanks again Maruska)

https://grabcad.com/library/millennium-falcon-captain-s-chair

J

Archive&Future

Sr Member

Thanks for the suggestions fellas, Maruska's files have been invaluable since step one !

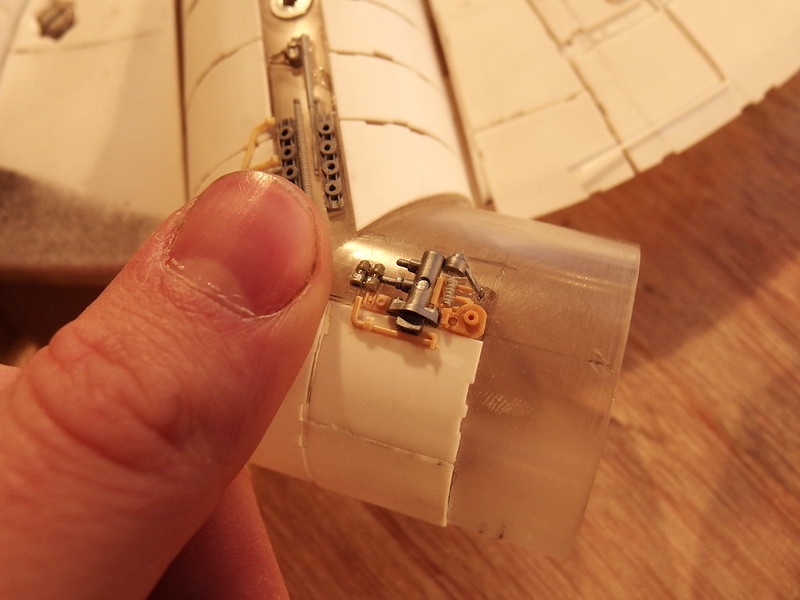

After messing around with Sketchup, my very basic trigonometry skills and head-scratching I decided the tunnel I already built was still workable.

I remade the internal mount for it, which is in turn glued AND bolted into the main chassis.

It's probably the messiest part of the build so far, but I'll make sure to crisp it up.

After messing around with Sketchup, my very basic trigonometry skills and head-scratching I decided the tunnel I already built was still workable.

I remade the internal mount for it, which is in turn glued AND bolted into the main chassis.

It's probably the messiest part of the build so far, but I'll make sure to crisp it up.

Archive&Future

Sr Member

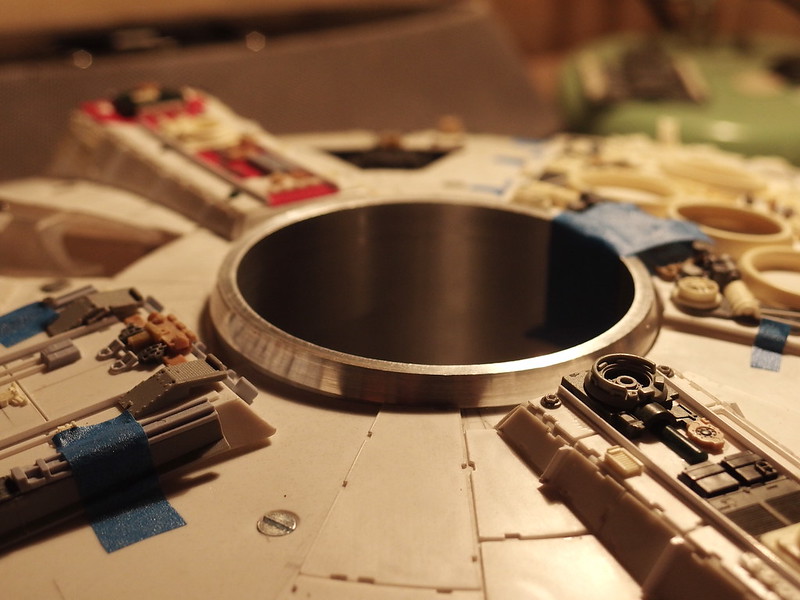

Now that the panelling is added I'm actually feeling quite pleased with the tunnel. It'll just need some TLC to blend into the hull, though I may need to stray from strict accuracy to make it feel right

Archive&Future

Sr Member

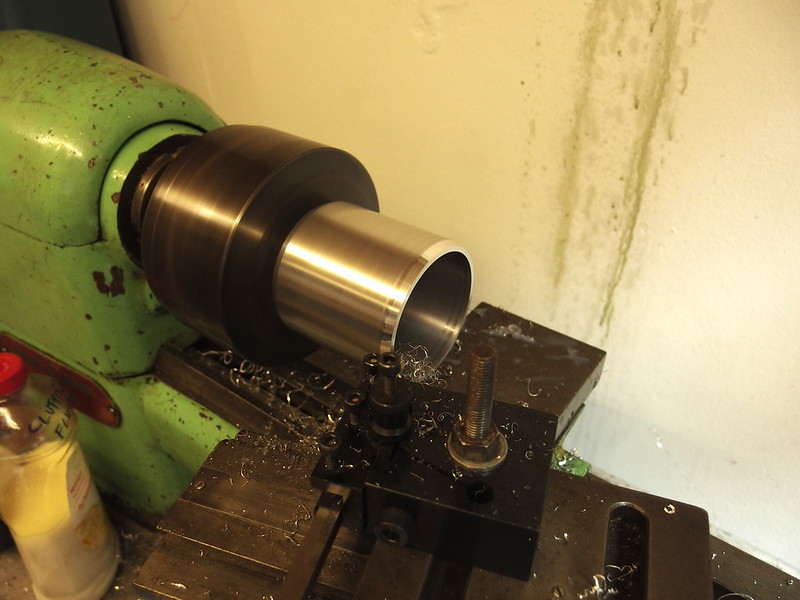

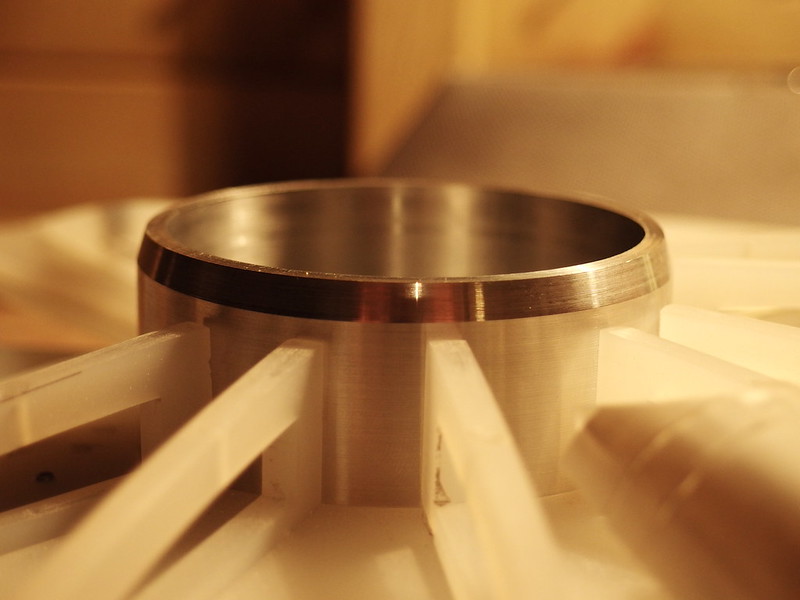

One of the studios I often do freelance work for is kitted out with a metal lathe, so after work today I reduced the 80mm aluminium tube I bought a few weeks ago by 1mm across its diameter.

Once that was done, I parted it down to a 78mm total height, then it was simply a case of angling the tool block to 18º to cut the bevelled turret wall.....If I sound vague, it's because I'm a total novice at machining, but regardless, I'm pleased with it

Once that was done, I parted it down to a 78mm total height, then it was simply a case of angling the tool block to 18º to cut the bevelled turret wall.....If I sound vague, it's because I'm a total novice at machining, but regardless, I'm pleased with it

newmagrathea

Sr Member

That is next level stuff

Archive&Future

Sr Member

Well, the aluminium central turret system works a treat.

Weighs at least a kilo by now....my poor little arm was straining

Weighs at least a kilo by now....my poor little arm was straining

Similar threads

- Replies

- 40

- Views

- 3,574

- Replies

- 5

- Views

- 1,449

- Replies

- 24

- Views

- 1,155

- Replies

- 2

- Views

- 2,177