Props N at

New Member

Hello everyone! This is my first official thread here, although this is certainly not my first replica!

I'm currently working on the Laser Musket from Fallout 4. Specifically, I'm doing the "extended long barrel" variant seen in much of the promo art. All said and done, it will also include a lighted core and sounds!

I've already poured a month and a half's worth of weekends into this project, so I figure I'm at a pretty safe point to start posting pictures! Here's my progress so far:

Now, to try and keep the thread a little light I'm only posting some of my pictures for now, but I took plenty more, and am happy to share if anyone is interested in them!

Here's the slightly abbreviated description of the work I've done, too (Lifted straight from my tumblr post about it):

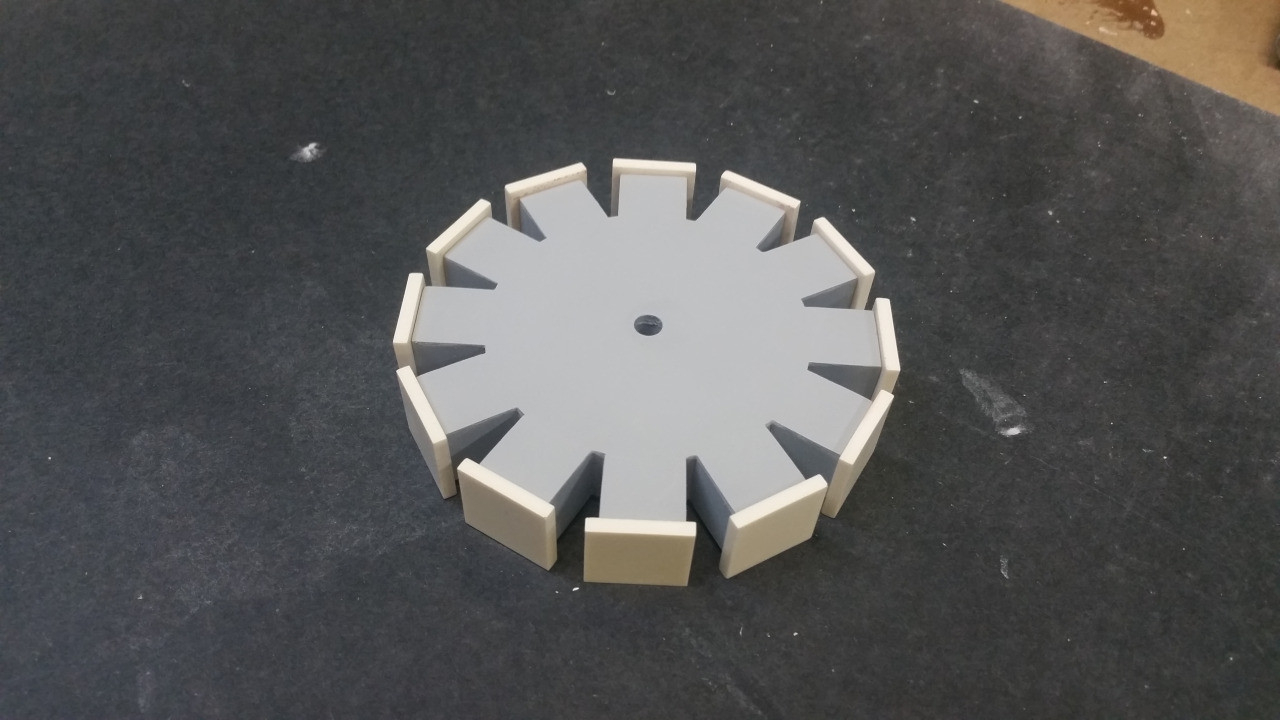

The “coil” section was made by making a single one of the blocks coming off of the center disk, then molding it and casting a set of twelve more. That way I had matching set with without having to make twelve individual pieces, same goes for the the square caps on top. They were then arrayed around a sintra disk.

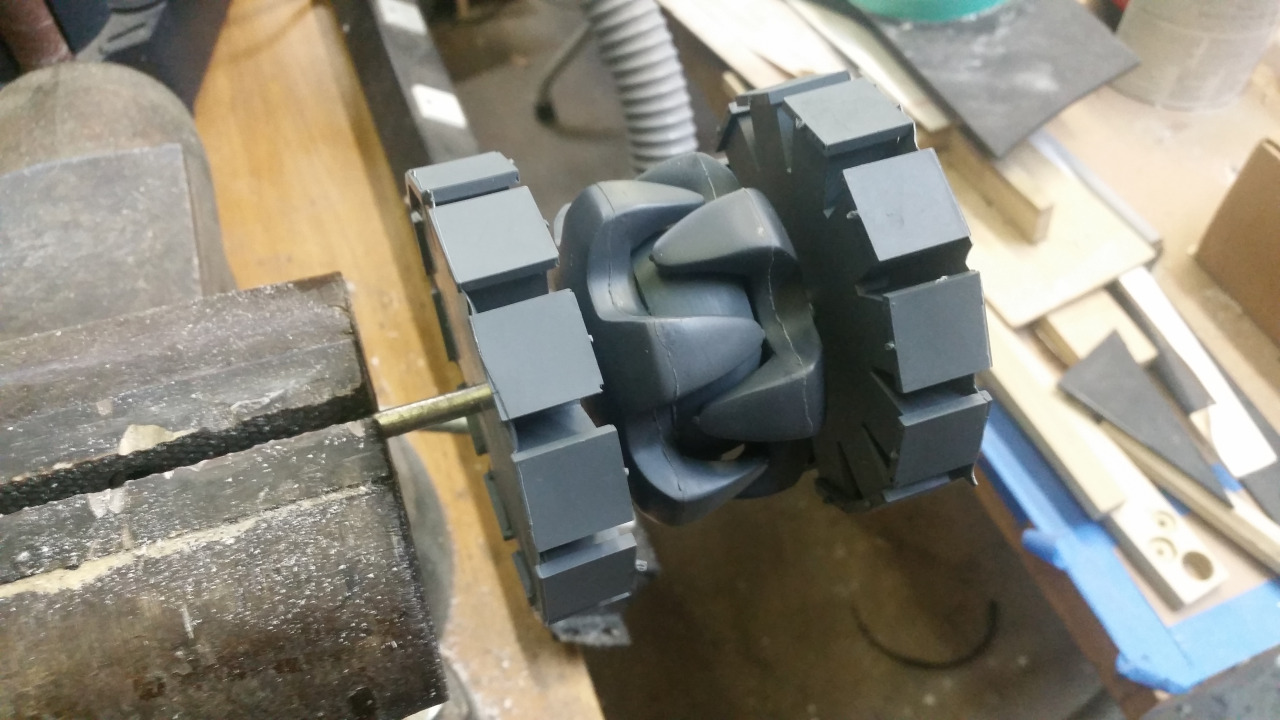

The “claw” piece, as it turns out, is actually based off of an alternator rotor. I considered trying to find one, but ended up deciding to build my own, which gave me more control over the final design, and allowed me to make a mold. The claw is the only piece that has, and probably will be, 3d printed. It was designed and molded in CAD, and printed it on my Solidoodle.

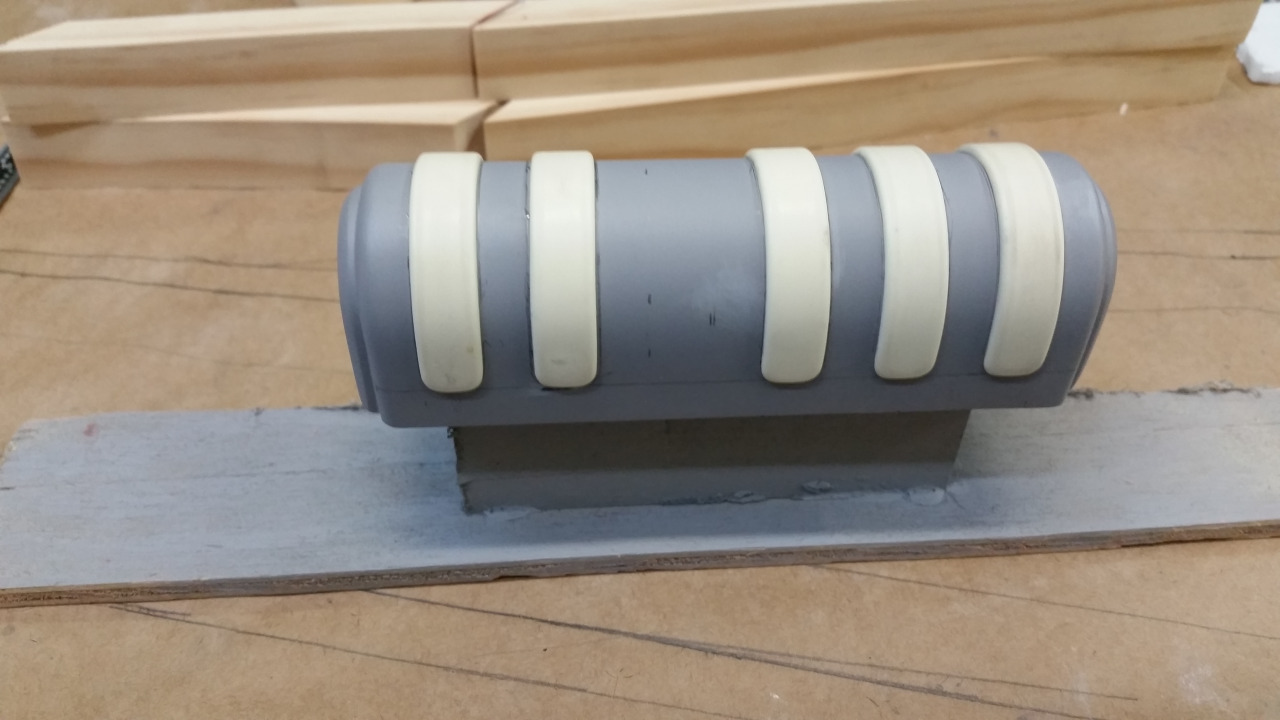

After staring at the Musket, it occurred to me that the “extended barrel” mod was built off of the original musket’s iron barrel. The barrel is octagonal, which is a rare stock material to find, and meant I had to make my own. It was cut, very carefully, on a table saw from a piece of alder. The cast barrels have a piece of 1/4" pencil rod out the end to strengthen it and give it a better attachment point for the rest of the gun.

The front grip comes off of the laser rifle. It was made from a piece of alder, then layered with some semi-flexible urethane to build the second step up. The finger grips were made from a piece of styrene that I shaped and finished flat, then molded. They were cast with Siltool resin, and wrapped around the grip before the resin completely cured.

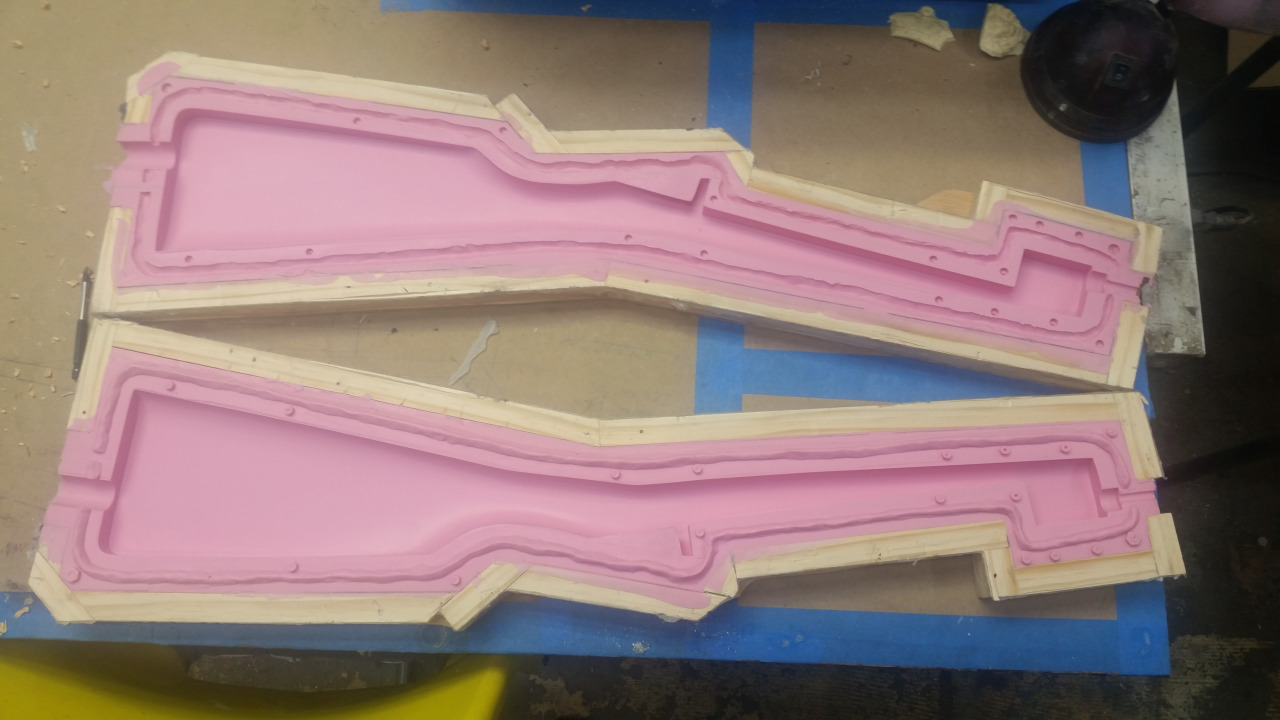

The stock is made from two stacked pine 1x6′s. It was shaped, then smoothed with bondo. The biggest challenge came in hollowing out the groove where the original musket bolt would have been. To try and conserve some silicone, I made a tight fitting wooden mold jacket. So far, the biggest I’ve made yet!

I cast the stock in a few stages, first by brushing a layer of siltool in both halves, then I placed a piece of 1/4″ pencil rod protruding from the front to give it a mounting point for the grip. I also placed a 2 pieces of 1/8″ pencil rod in the front to support it where it thins. The mold was closed and the the piece was filled solid to the back of the had grips. Then I poured the seam of the butt with a thin layer, leaving the center hollow.

And here's the point I'm at right now!

I plan on doing this thing in kit form, and have done molds of everything so far. That's been the most tedious part.

Well, I'm sure I've glossed over a good bit of my work to get to this point, so if anyone has any questions, please ask!

I'm currently working on the Laser Musket from Fallout 4. Specifically, I'm doing the "extended long barrel" variant seen in much of the promo art. All said and done, it will also include a lighted core and sounds!

I've already poured a month and a half's worth of weekends into this project, so I figure I'm at a pretty safe point to start posting pictures! Here's my progress so far:

Now, to try and keep the thread a little light I'm only posting some of my pictures for now, but I took plenty more, and am happy to share if anyone is interested in them!

Here's the slightly abbreviated description of the work I've done, too (Lifted straight from my tumblr post about it):

The “coil” section was made by making a single one of the blocks coming off of the center disk, then molding it and casting a set of twelve more. That way I had matching set with without having to make twelve individual pieces, same goes for the the square caps on top. They were then arrayed around a sintra disk.

The “claw” piece, as it turns out, is actually based off of an alternator rotor. I considered trying to find one, but ended up deciding to build my own, which gave me more control over the final design, and allowed me to make a mold. The claw is the only piece that has, and probably will be, 3d printed. It was designed and molded in CAD, and printed it on my Solidoodle.

After staring at the Musket, it occurred to me that the “extended barrel” mod was built off of the original musket’s iron barrel. The barrel is octagonal, which is a rare stock material to find, and meant I had to make my own. It was cut, very carefully, on a table saw from a piece of alder. The cast barrels have a piece of 1/4" pencil rod out the end to strengthen it and give it a better attachment point for the rest of the gun.

The front grip comes off of the laser rifle. It was made from a piece of alder, then layered with some semi-flexible urethane to build the second step up. The finger grips were made from a piece of styrene that I shaped and finished flat, then molded. They were cast with Siltool resin, and wrapped around the grip before the resin completely cured.

The stock is made from two stacked pine 1x6′s. It was shaped, then smoothed with bondo. The biggest challenge came in hollowing out the groove where the original musket bolt would have been. To try and conserve some silicone, I made a tight fitting wooden mold jacket. So far, the biggest I’ve made yet!

I cast the stock in a few stages, first by brushing a layer of siltool in both halves, then I placed a piece of 1/4″ pencil rod protruding from the front to give it a mounting point for the grip. I also placed a 2 pieces of 1/8″ pencil rod in the front to support it where it thins. The mold was closed and the the piece was filled solid to the back of the had grips. Then I poured the seam of the butt with a thin layer, leaving the center hollow.

And here's the point I'm at right now!

I plan on doing this thing in kit form, and have done molds of everything so far. That's been the most tedious part.

Well, I'm sure I've glossed over a good bit of my work to get to this point, so if anyone has any questions, please ask!

Last edited by a moderator: