mung

Sr Member

Here is my next RC project, components of which have been kicking around for some time.

I'm calling it a Moon Bus.

It is in no way connected with the hovering vehicle from 2001 a Space Odyssey, this one has wheels and big tyres.

The design started with the tyres.

I had a set of Imex truck pull Clodbuster tyres sitting around for quite a few years, but have never had any rims to fit.

One of my random Ebay trawls came up with a really cool set of rims that would be perfect for these tyres and a sci-fi

flavoured project.

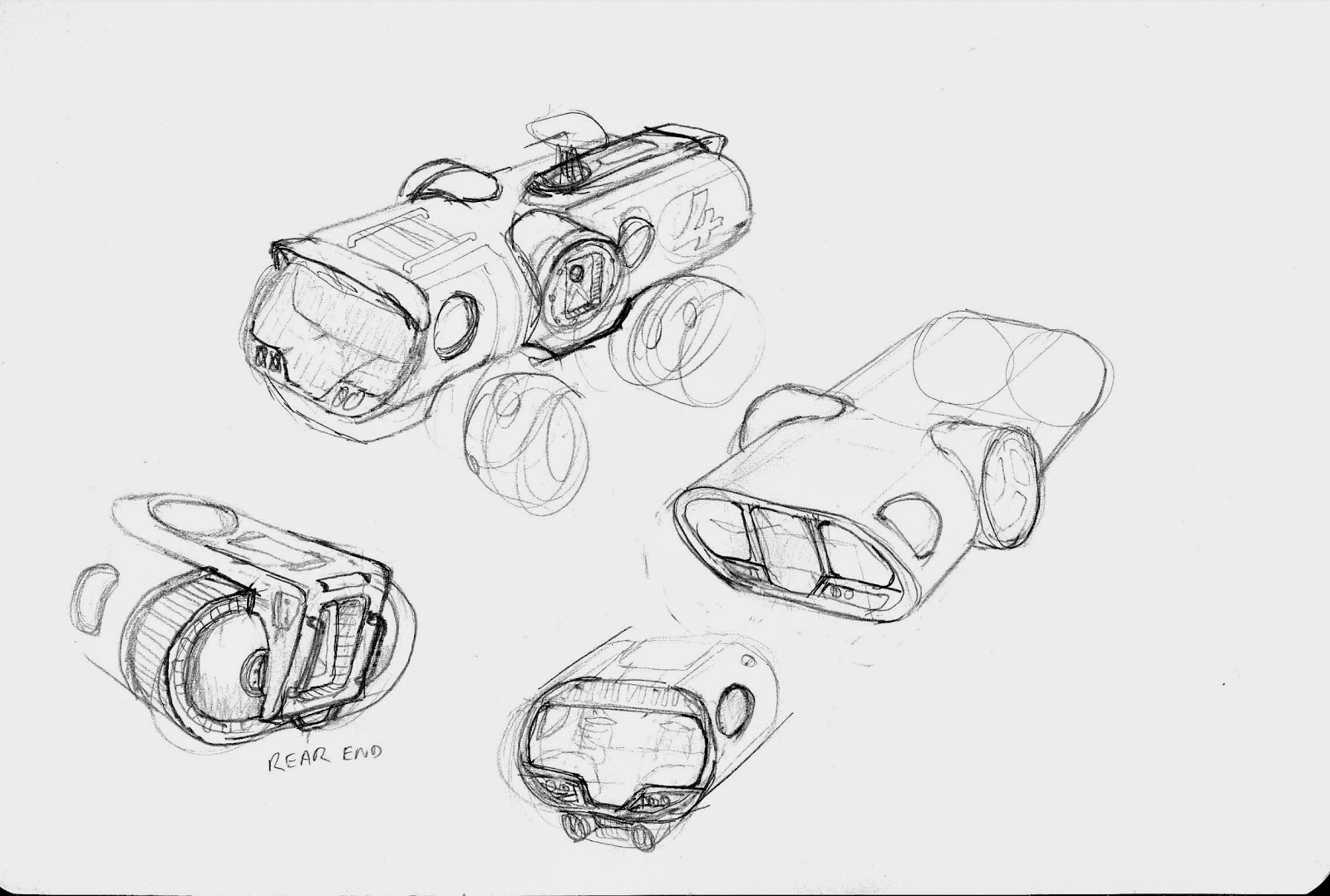

Below are the rough design thumbnails from my sketchbook.

I only ever do enough drawing to get the idea of where to start and the general direction to take, the rest is down to

actually building the main shapes, seeing and touching the volumes and improvising from there.

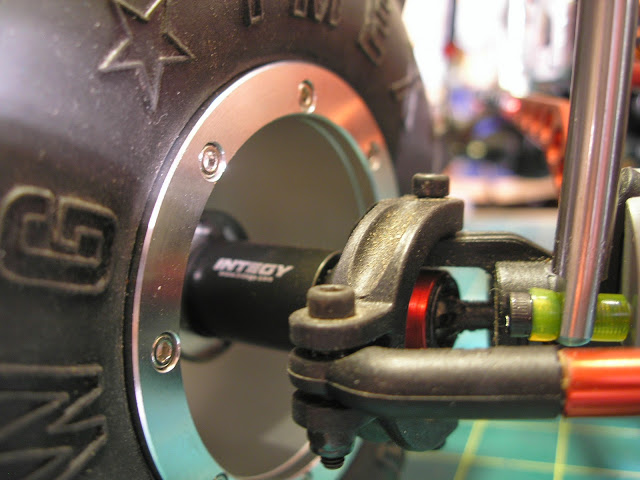

The rims are an older version of the RC4WD Clod beadlocks which are no longer available.

I think you might still get a later revised version with a separate interchangeable hub.

These have a 14mm hex socket and came with some splined 14mm hexes designed to mate with the Tamiya Clod-Buster splined axles.

They are really beautifully machined and this set does not appear to have been used much, if at all.

The front beadlock rings have a number of cosmetic non-functional very short cap screws with 8 functional ones like the back rings.

The beadlocks actually completely seal the tyre so they remain effectively pumped up without any foams in place which is handy

given that the tyres didn't come with any foams.

They have sat around like this for several months now and still have not deflated.

They have a massive machined black anodised hub which screws in to hide the wheel nut and the rims are really thick and quite heavy.

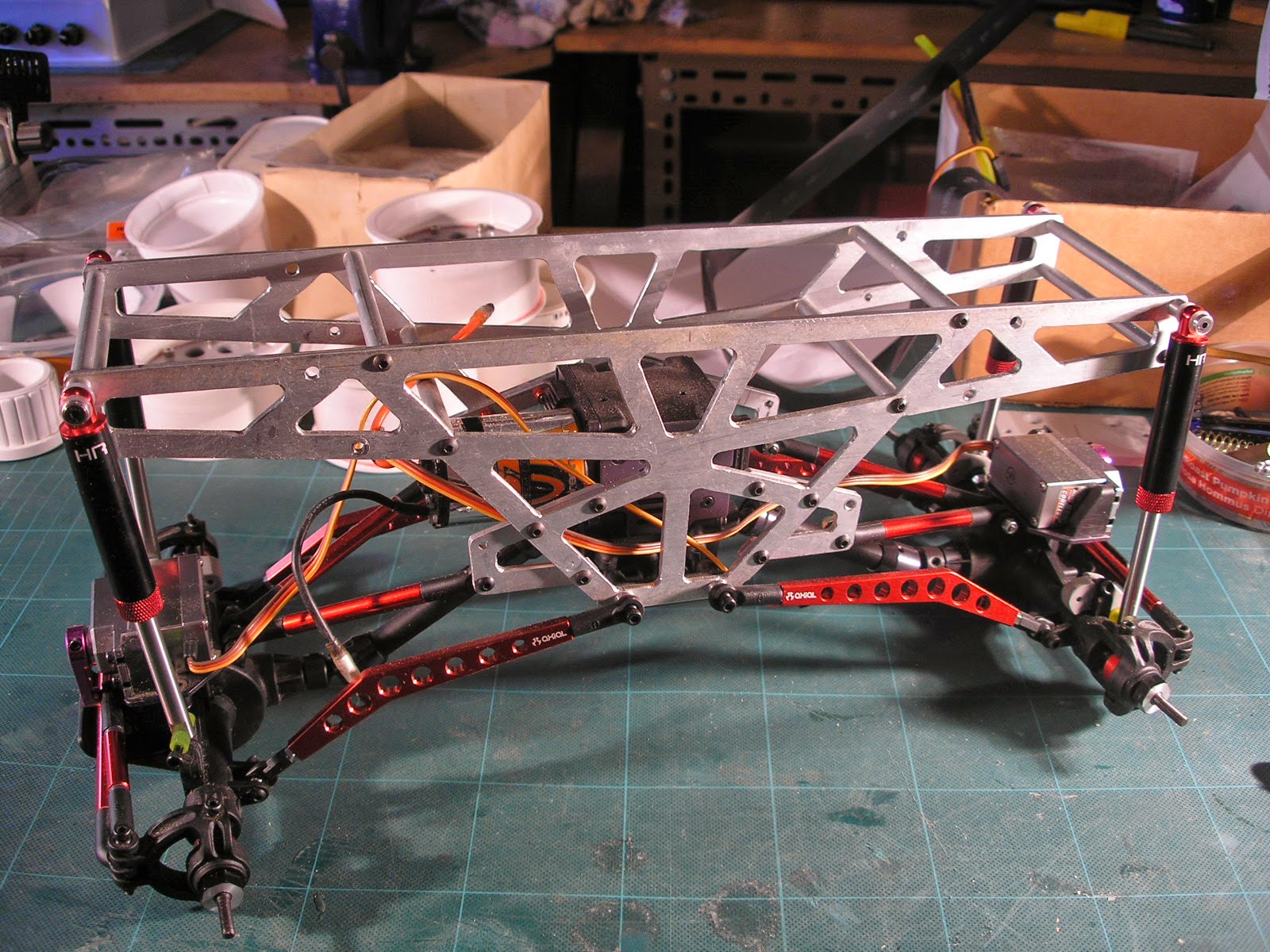

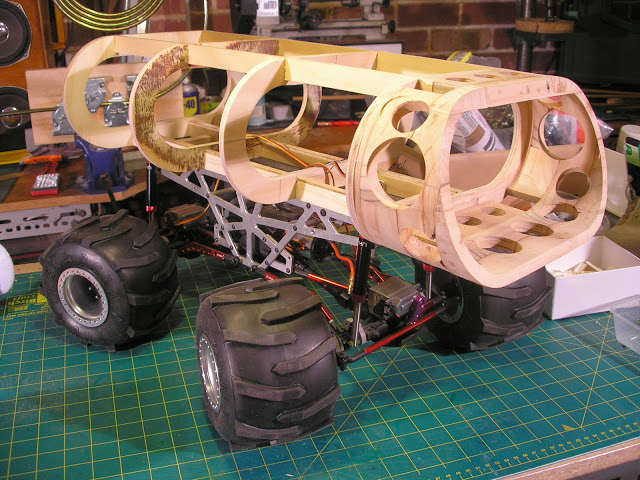

The two chassis plates I made from 3mm aluminium sheet, drawn up in Delta Cad, printed out, spray glued onto the

aluminium and all the inner corner radiuses were drilled out.

I then used a scroll saw to cut out all the holes finishing up with hand filing.

The blades for the scroll saw though designed for wood will cut thin aluminium but dont last as long.

I went through quite a few.

These were made way back in 2002.

The shape being inspired by the Tamiya TXT-1 monster truck.

I was planning to build a monster truck at the time but it never got very far.

The chassis plates have been cut and shunted a bit.

Originally the idea for the monster truck was for the battery to sit low down on the extended sides, these have now been

chopped and moved to support the upper links.

The axles are once again a set from a Venom Creeper that have a manually switchable diff lock.

The transmission was originally from a Creeper, as shown in these early pictures, but that was put into the Toybash

truck project and it has been replaced by an Axial SCX10 transmission which has a slipper clutch.

The lower links are Axial machined high clearance links just because they look cool and I already had a pair which I

got to try out on another project for which they didn't turn out to be suitable.

As usual it took a lot of fiddling to sort out the shock placement. They have ended up pretty much in the monster truck vertical position.

In fact this was the test bed where a lot of mechanical problems were tried out for the Toybash truck project.

The shocks are a set of Hot Racing oil-less ones that rely on air damping. They look cool but I am not all that convinced of their efficacy.

Once again they have to be able to push up the heavy body without it flopping over to one side that the usual angled

crawler shock position encourages.

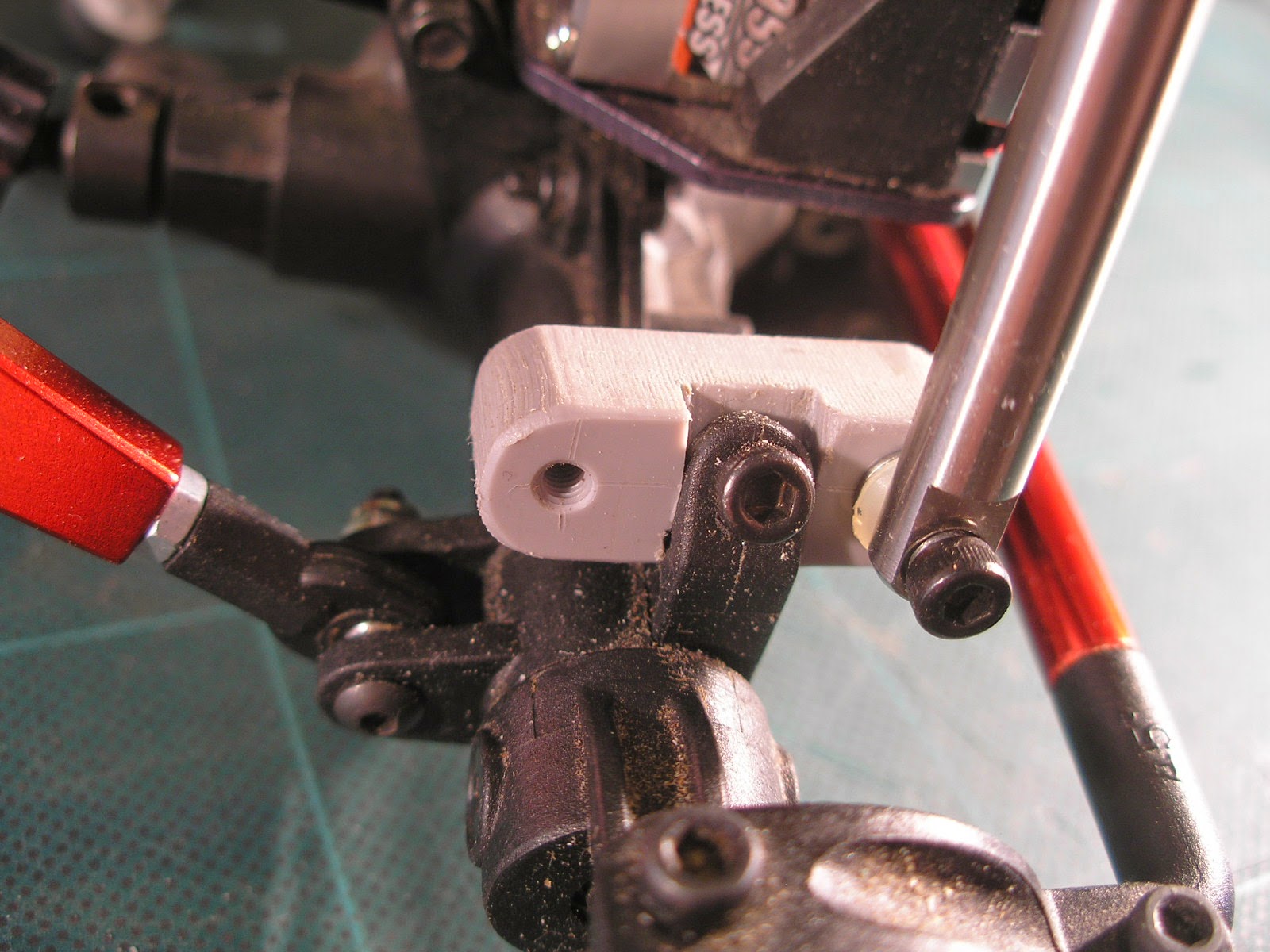

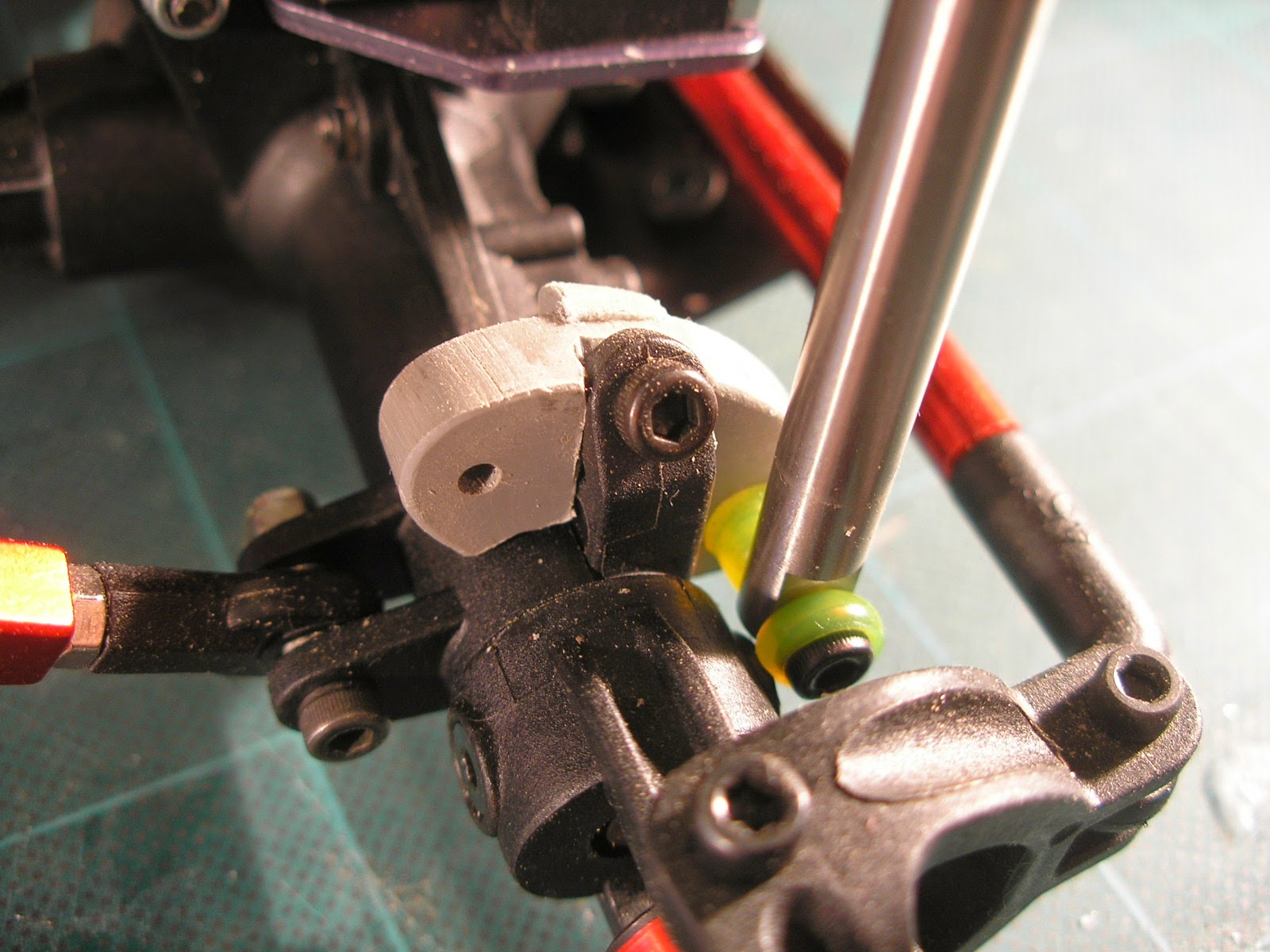

The Creeper axles have a really annoying angled shock link mount so I had to make up a set of PVC adaptors so the shocks

could mount vertically without binding.

They are captured by some vinyl fuel tubing bushes which permit flexibility of movement.

The first set I made were straight but this meant the shocks were too tall so I made some curved versions.

The curved versions restricted the steering throw a bit and I did recently modify the mounts to cure this to be covered in the next post.

Thoughtfully a second hole was added in case there was a need for a sway bar set up.

Above are the original straight mounts and below are the revised curved mounts.

The other difficulty was getting those beadlocks to mount up. I needed some form of widener to get enough clearance

so the rims did not foul the knuckles and the links especially when turned.

I ended up getting some Integy 12mm to14mm hex adaptor wideners.

They came with two sets of barrel nuts, short and long. The long ones were not long enough.

Those beadlocks have about 10mm thick hubs whereas most plastic wheels have only about 3 or 4mm thickness.

The project ground to a halt for many months at this point while I contemplated what to do.

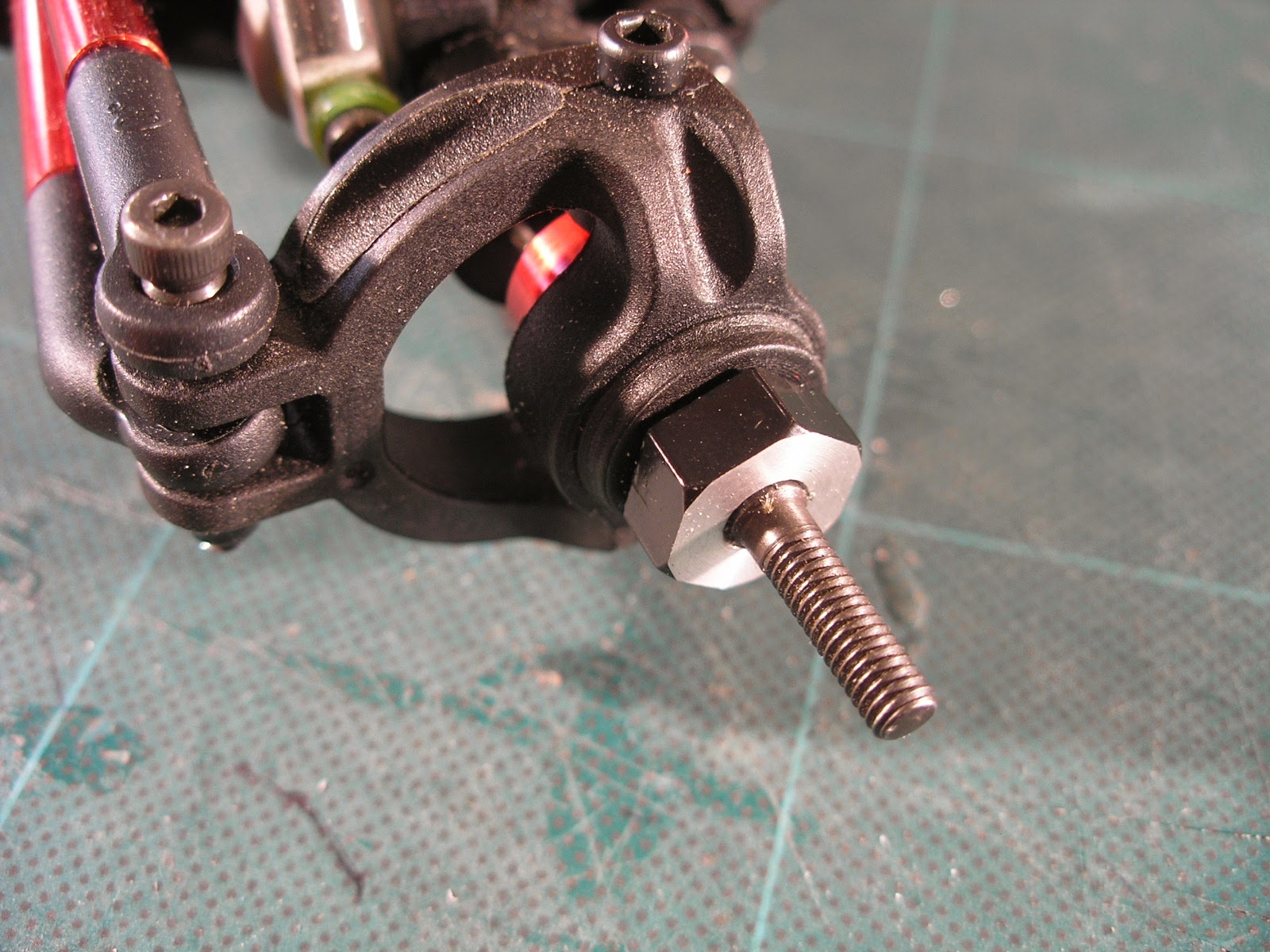

In the end I made my own barrel nuts from some 6mm bolts.

I got some 60mm in length M6 bolts and cut off the thread.

The remaining bolt shoulders were drilled out and tapped M4 to fit the axle thread and the beadlocks had to be drilled

out slightly to fit the 6mm bolts which are actually only 5.8mm in diameter. I have a set of metric drills that go from

1 to 5.9mm in 0.1mm steps, very useful for tapping and clearance hole sizes.

I felt that the Integy wideners were too wide, if I could find something that has a much smaller offset and a 14mm hex I would swap them out.

It would also reduce the amount of tyre scrub when the steering is turned.

In an attempt to shorten the offset as much as possible I used machined down Axial narrow aluminium hexes designed for 1.9 sized wheels.

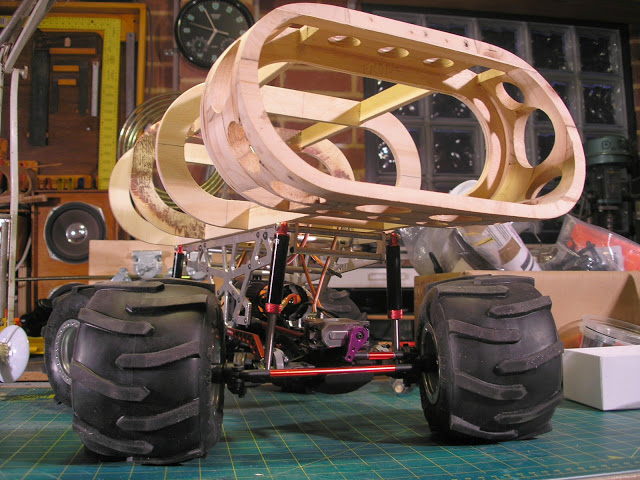

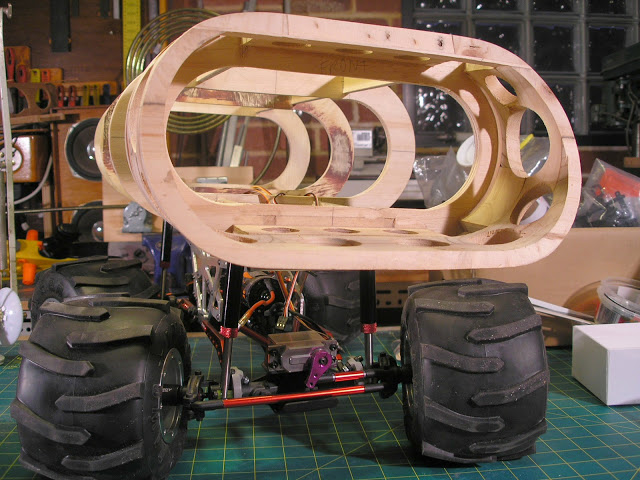

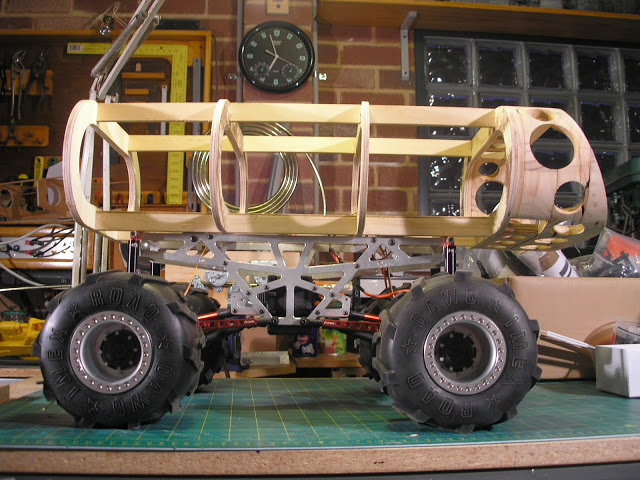

A start was made on the body. A wooden frame has been cut and assembled.

The body is held on by 4 X M4 cap screws which pass through holes in the chassis and screw into threaded plates screwed to the wooden frame.

All that work took place many months ago, more recent work described in a following post brings this project up to date.

I'm calling it a Moon Bus.

It is in no way connected with the hovering vehicle from 2001 a Space Odyssey, this one has wheels and big tyres.

The design started with the tyres.

I had a set of Imex truck pull Clodbuster tyres sitting around for quite a few years, but have never had any rims to fit.

One of my random Ebay trawls came up with a really cool set of rims that would be perfect for these tyres and a sci-fi

flavoured project.

Below are the rough design thumbnails from my sketchbook.

I only ever do enough drawing to get the idea of where to start and the general direction to take, the rest is down to

actually building the main shapes, seeing and touching the volumes and improvising from there.

The rims are an older version of the RC4WD Clod beadlocks which are no longer available.

I think you might still get a later revised version with a separate interchangeable hub.

These have a 14mm hex socket and came with some splined 14mm hexes designed to mate with the Tamiya Clod-Buster splined axles.

They are really beautifully machined and this set does not appear to have been used much, if at all.

The front beadlock rings have a number of cosmetic non-functional very short cap screws with 8 functional ones like the back rings.

The beadlocks actually completely seal the tyre so they remain effectively pumped up without any foams in place which is handy

given that the tyres didn't come with any foams.

They have sat around like this for several months now and still have not deflated.

They have a massive machined black anodised hub which screws in to hide the wheel nut and the rims are really thick and quite heavy.

The two chassis plates I made from 3mm aluminium sheet, drawn up in Delta Cad, printed out, spray glued onto the

aluminium and all the inner corner radiuses were drilled out.

I then used a scroll saw to cut out all the holes finishing up with hand filing.

The blades for the scroll saw though designed for wood will cut thin aluminium but dont last as long.

I went through quite a few.

These were made way back in 2002.

The shape being inspired by the Tamiya TXT-1 monster truck.

I was planning to build a monster truck at the time but it never got very far.

The chassis plates have been cut and shunted a bit.

Originally the idea for the monster truck was for the battery to sit low down on the extended sides, these have now been

chopped and moved to support the upper links.

The axles are once again a set from a Venom Creeper that have a manually switchable diff lock.

The transmission was originally from a Creeper, as shown in these early pictures, but that was put into the Toybash

truck project and it has been replaced by an Axial SCX10 transmission which has a slipper clutch.

The lower links are Axial machined high clearance links just because they look cool and I already had a pair which I

got to try out on another project for which they didn't turn out to be suitable.

As usual it took a lot of fiddling to sort out the shock placement. They have ended up pretty much in the monster truck vertical position.

In fact this was the test bed where a lot of mechanical problems were tried out for the Toybash truck project.

The shocks are a set of Hot Racing oil-less ones that rely on air damping. They look cool but I am not all that convinced of their efficacy.

Once again they have to be able to push up the heavy body without it flopping over to one side that the usual angled

crawler shock position encourages.

The Creeper axles have a really annoying angled shock link mount so I had to make up a set of PVC adaptors so the shocks

could mount vertically without binding.

They are captured by some vinyl fuel tubing bushes which permit flexibility of movement.

The first set I made were straight but this meant the shocks were too tall so I made some curved versions.

The curved versions restricted the steering throw a bit and I did recently modify the mounts to cure this to be covered in the next post.

Thoughtfully a second hole was added in case there was a need for a sway bar set up.

Above are the original straight mounts and below are the revised curved mounts.

The other difficulty was getting those beadlocks to mount up. I needed some form of widener to get enough clearance

so the rims did not foul the knuckles and the links especially when turned.

I ended up getting some Integy 12mm to14mm hex adaptor wideners.

They came with two sets of barrel nuts, short and long. The long ones were not long enough.

Those beadlocks have about 10mm thick hubs whereas most plastic wheels have only about 3 or 4mm thickness.

The project ground to a halt for many months at this point while I contemplated what to do.

In the end I made my own barrel nuts from some 6mm bolts.

I got some 60mm in length M6 bolts and cut off the thread.

The remaining bolt shoulders were drilled out and tapped M4 to fit the axle thread and the beadlocks had to be drilled

out slightly to fit the 6mm bolts which are actually only 5.8mm in diameter. I have a set of metric drills that go from

1 to 5.9mm in 0.1mm steps, very useful for tapping and clearance hole sizes.

I felt that the Integy wideners were too wide, if I could find something that has a much smaller offset and a 14mm hex I would swap them out.

It would also reduce the amount of tyre scrub when the steering is turned.

In an attempt to shorten the offset as much as possible I used machined down Axial narrow aluminium hexes designed for 1.9 sized wheels.

A start was made on the body. A wooden frame has been cut and assembled.

The body is held on by 4 X M4 cap screws which pass through holes in the chassis and screw into threaded plates screwed to the wooden frame.

All that work took place many months ago, more recent work described in a following post brings this project up to date.

Last edited: