cecrops props

Active Member

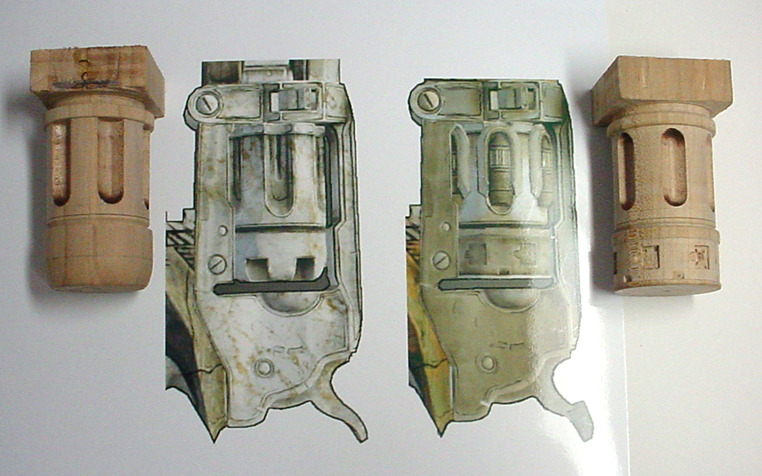

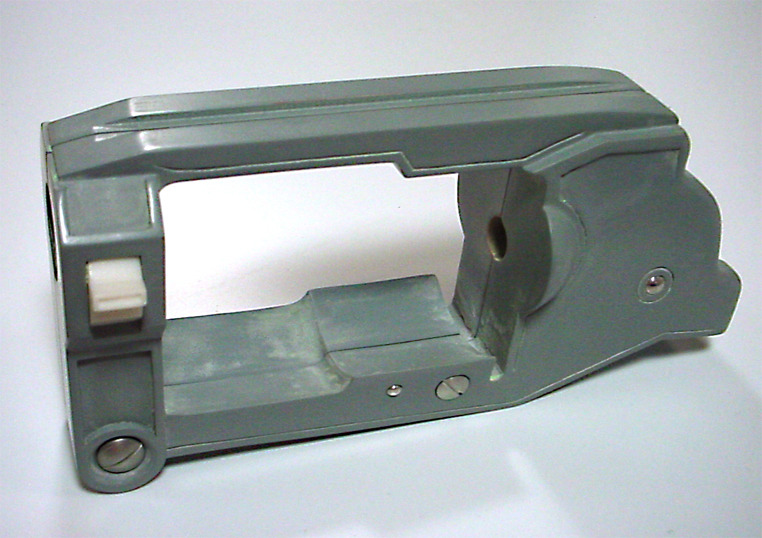

I am in the process of building the Jakobs pistol from Borderlands 2. This will be all of the parts to build the pure Jakobs pistols, such as the Iron and Rex series pistols pictured below.

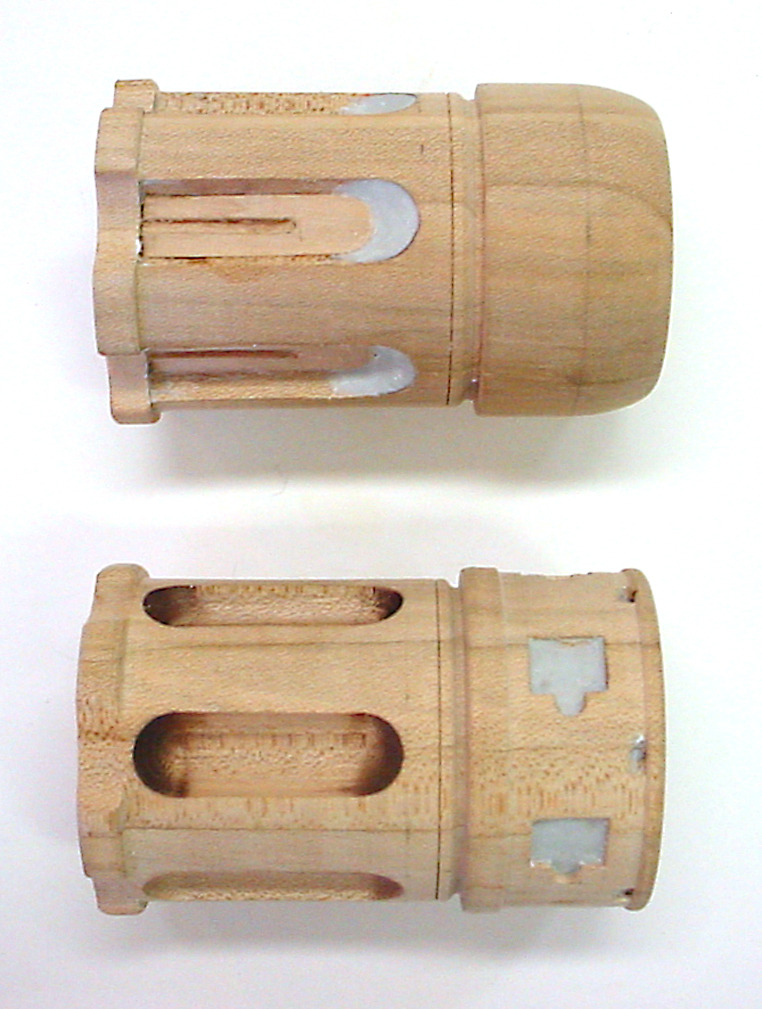

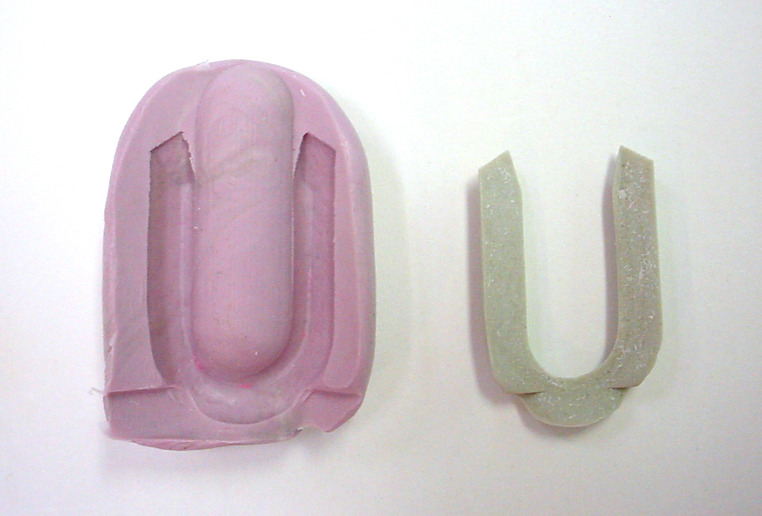

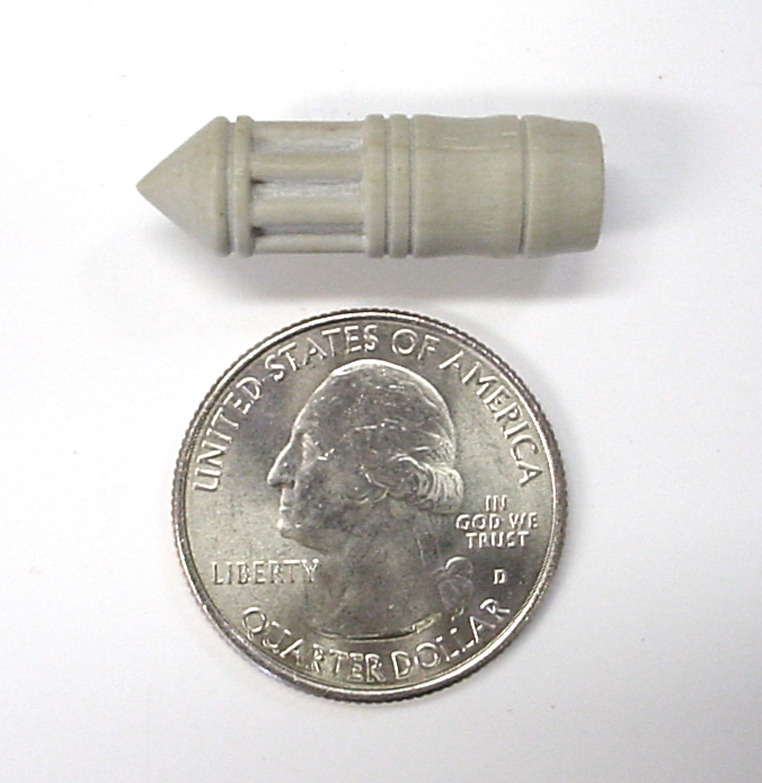

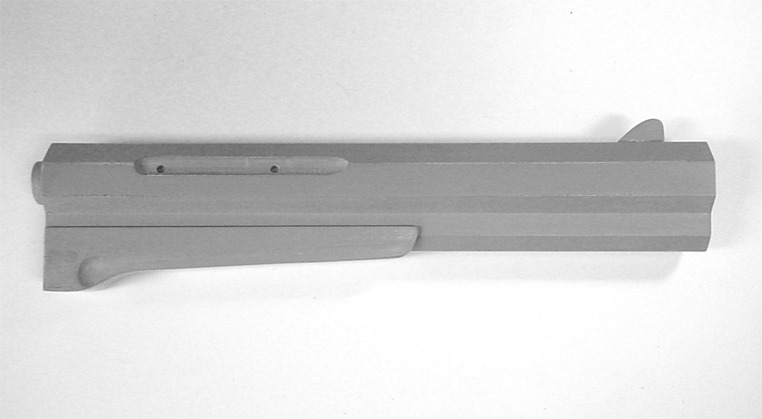

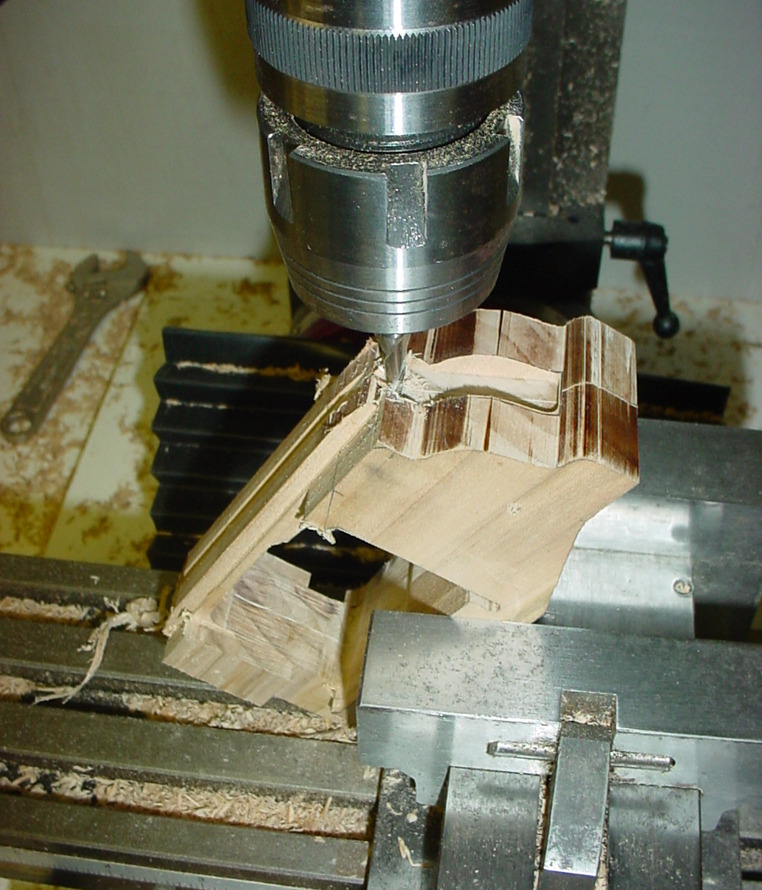

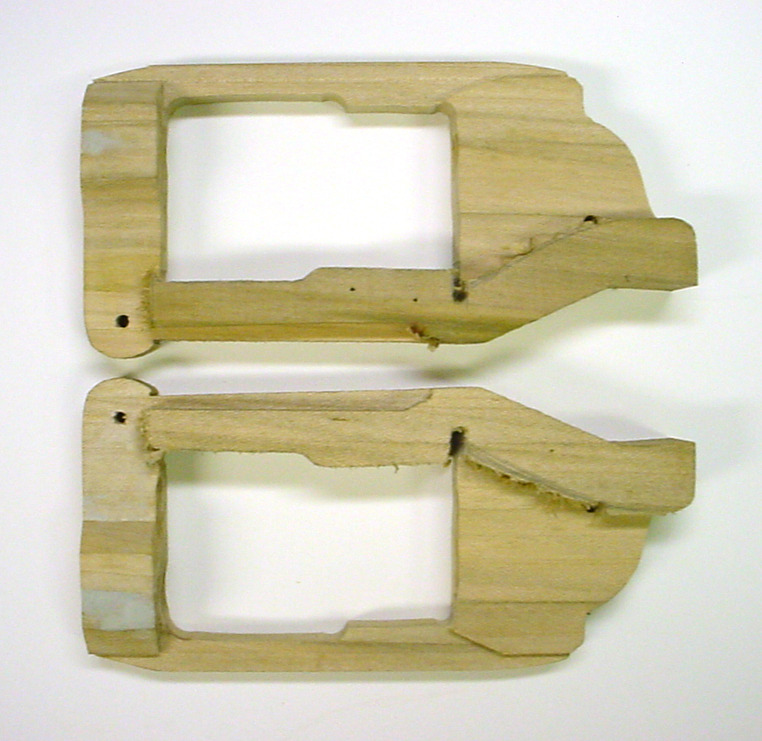

Here are the initial pieces blocked out in maple.

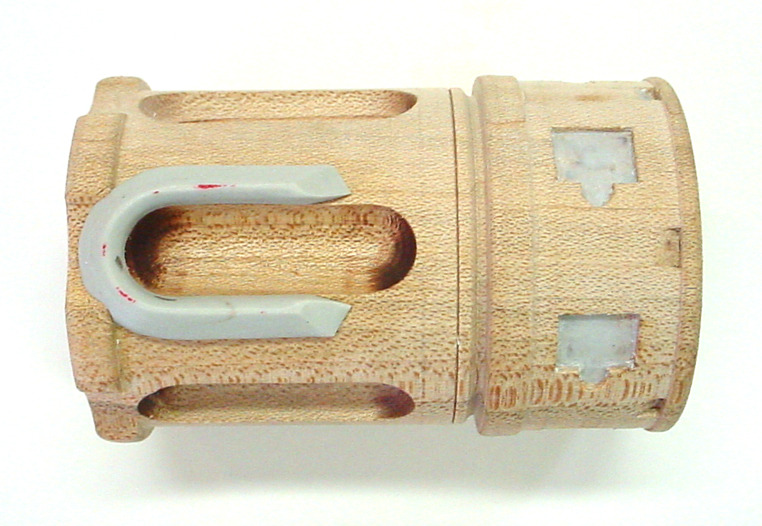

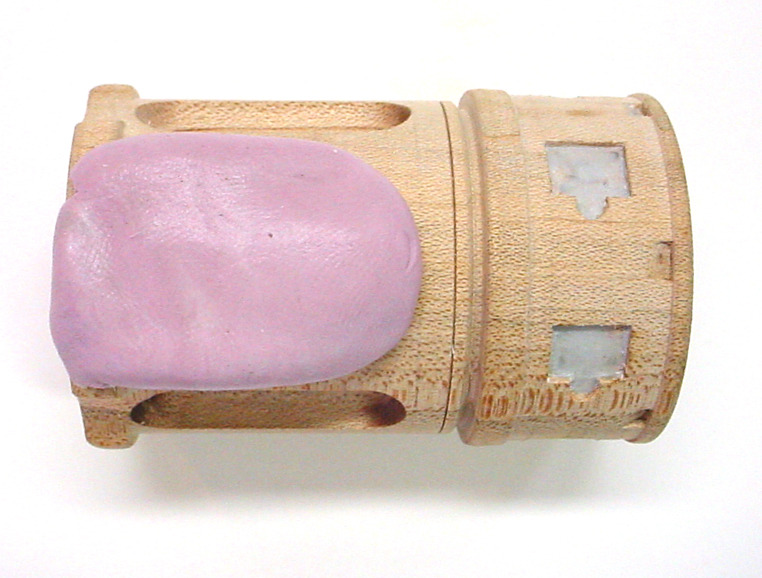

After looking at several alternatives, I chose to use maple to make the master model for several reasons. It is a traditional model making material in foundry work because it is dimensionally stable, has a very tight grain, is relatively inexpensive, and is easy to finish to a smooth surface. It can also be worked with both woodworking and metalworking tools.

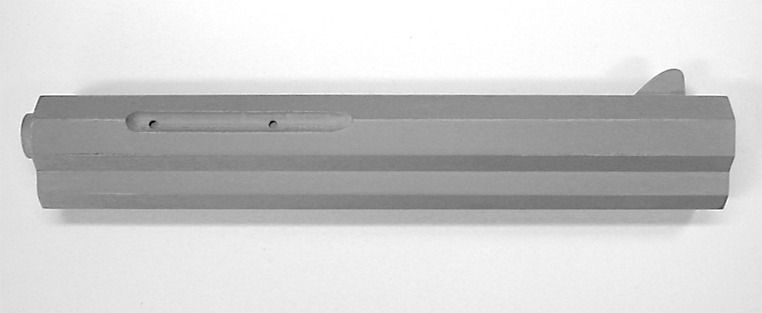

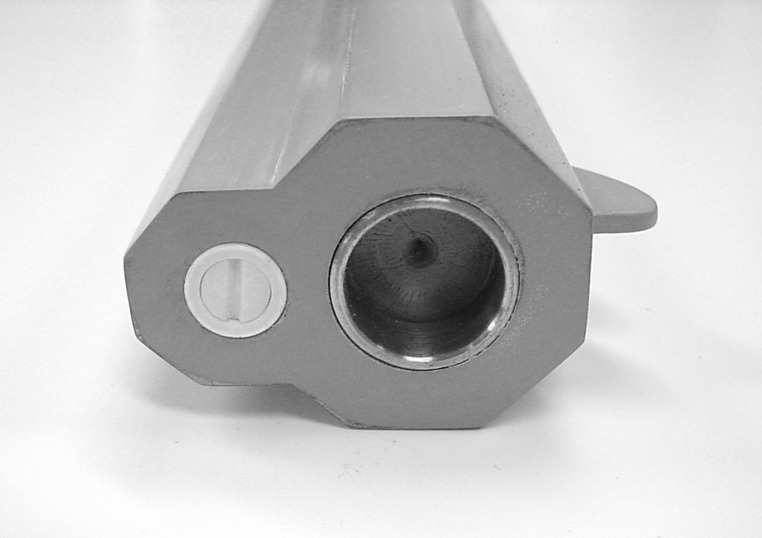

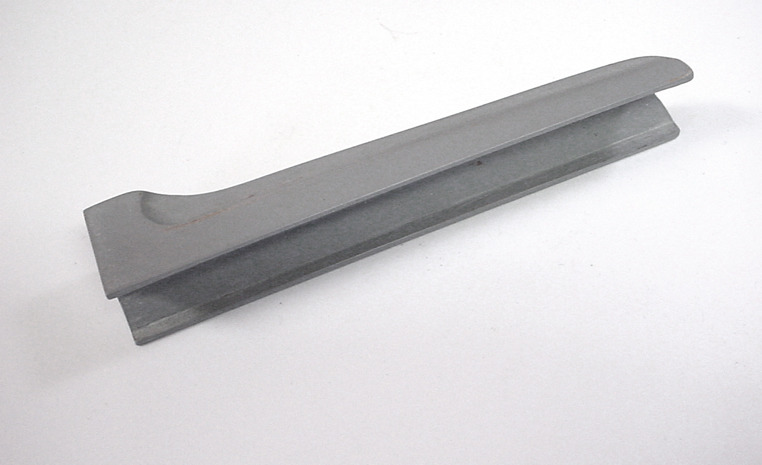

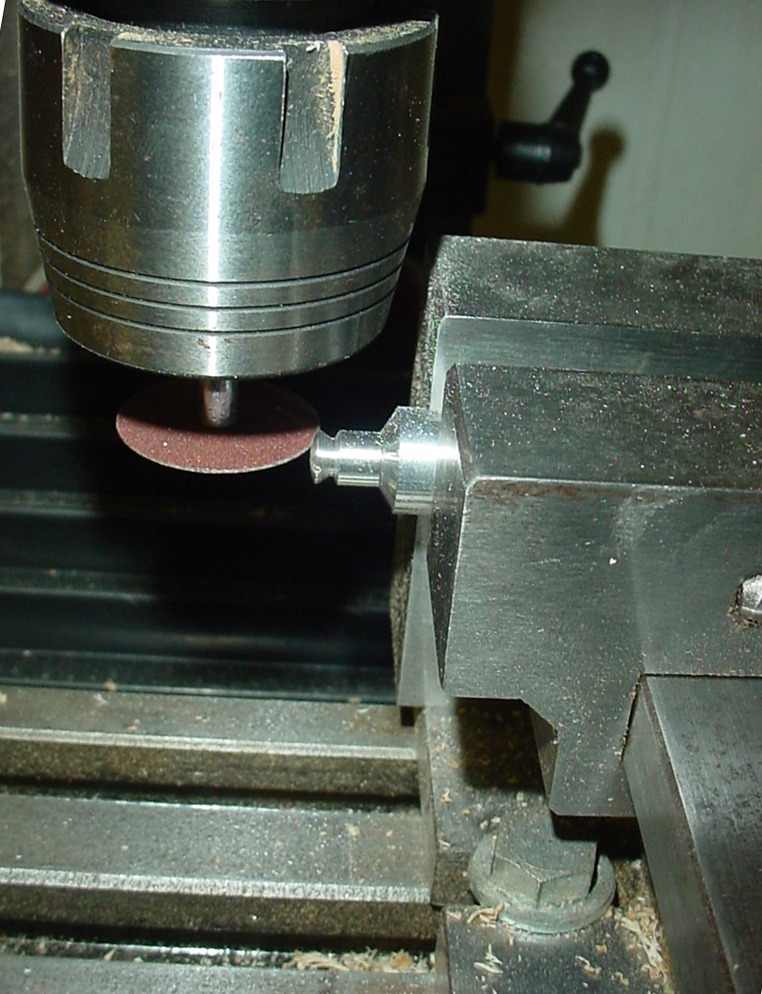

The barrel was cut to size and planed into the octagon profile with a block plane. Using a sheet of sandpaper on a flat surface and digital calipers, I was able to get it octagonal to within a few thousandths of an inch.

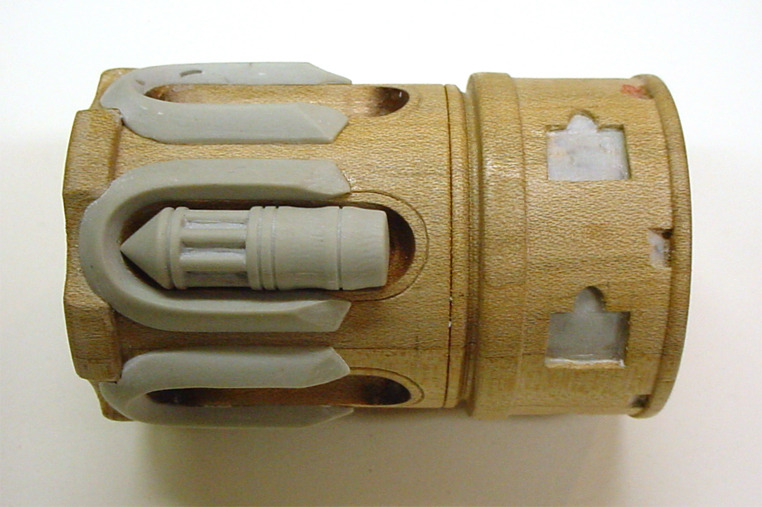

I’m making two cylinders because two different cylinders occur on the Jakobs pistols in the games, as can be seen on the screenshots above. I have also decided to make the parts for gun separated into the various parts that the Borderlands 2 gun generation system uses. That way, when I make other Borderlands pistols in the future, various parts can be interchanged to make all of the pistol variations in the games.

As I continue this build, I will be posting my progress, all the way to the end.

Here are the initial pieces blocked out in maple.

After looking at several alternatives, I chose to use maple to make the master model for several reasons. It is a traditional model making material in foundry work because it is dimensionally stable, has a very tight grain, is relatively inexpensive, and is easy to finish to a smooth surface. It can also be worked with both woodworking and metalworking tools.

The barrel was cut to size and planed into the octagon profile with a block plane. Using a sheet of sandpaper on a flat surface and digital calipers, I was able to get it octagonal to within a few thousandths of an inch.

I’m making two cylinders because two different cylinders occur on the Jakobs pistols in the games, as can be seen on the screenshots above. I have also decided to make the parts for gun separated into the various parts that the Borderlands 2 gun generation system uses. That way, when I make other Borderlands pistols in the future, various parts can be interchanged to make all of the pistol variations in the games.

As I continue this build, I will be posting my progress, all the way to the end.