Yeah that would be the case. Perhaps it was milled at first, then additional filing was performed to create the angles that we're seeing?

I thought about that (I've spent a lot of time thinking this through), but there are two problems with it. First, that's an awful lot of work for a small piece that's not going to read even on film in that much detail, so it would be unlikely to be done. Even the milling itself requires quite a bit of work -- setting up is time-consuming. So adding to that with more filing and such seems very wasteful.

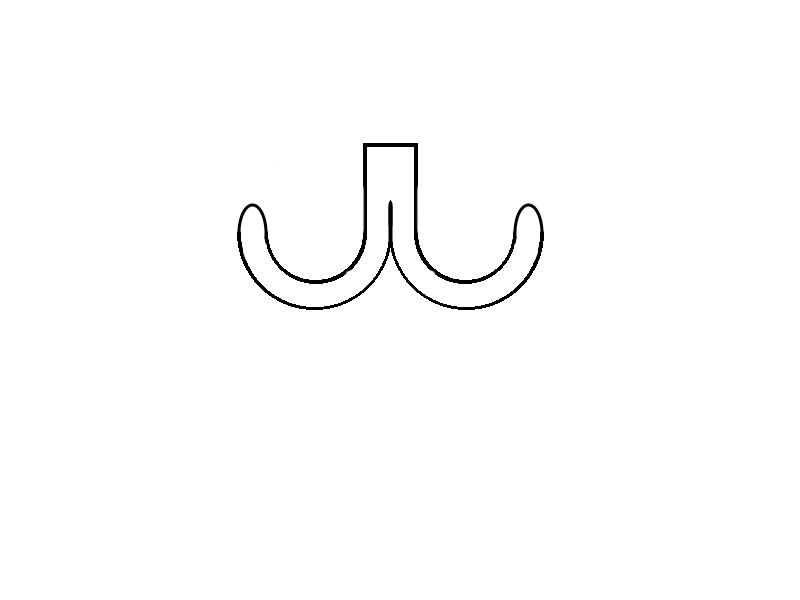

Second, the sides of the profile are mostly flat, which couldn't be done by

removing material from a circular profile. You'd have to

add material back to fill in the curves. So that's a non-starter IMO.

Today, you could do it with a very small (say 1/16") ball-nose on a CNC mill, doing multiple passes to carve out that profile. Very efficient. But in 1966, forget it.

So the more I've thought about the milling and casting ideas, the more doubts about them I've come up with. Just the opposite with the bent strip idea -- the more I think about it, the more good reasons for it I can think of. It's fast, requires only a bench vise and some hand tools (and possibly a quick trip to the bandsaw), and gets it done. Crude, but that's par for the course with phasers. And it creates the profile we see as a natural byproduct of the method, as opposed to time-consuming reshaping for no good reason.

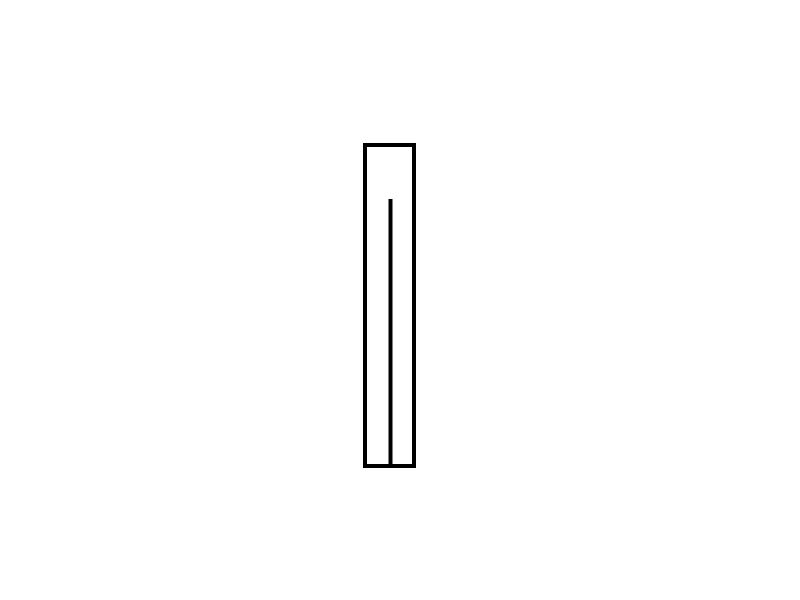

Something I'd forgotten about: This profile was in Matt Jeffries' drawings. Look at section B-B here, on the left side of the page:

So now we'd also have to think up a reason they would start by milling out a round profile and then do extra work (for four heroes) to get to the designed shape, when bending it would be very easy.

There hasn't been a phaser detail debate like this in years, it's deja vu all over again :cool And though I'm still skeptical, I'm starting to lean a bit closer to this at least being possible.

As well you should be skeptical. We all should be about all our certainties when it comes to props we've never inspected ourselves.

For instance, I'm skeptical about the milling + filing theory, but I can't say it's impossible.