Will Vale

Member

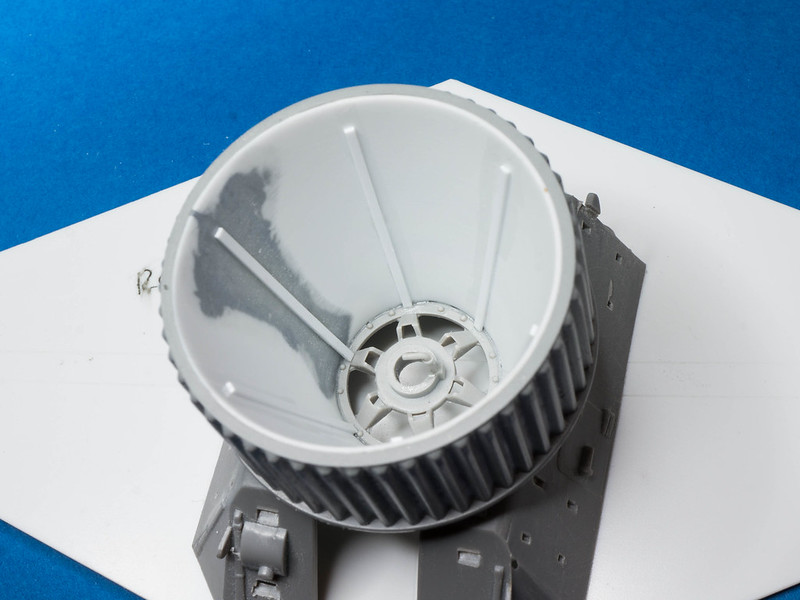

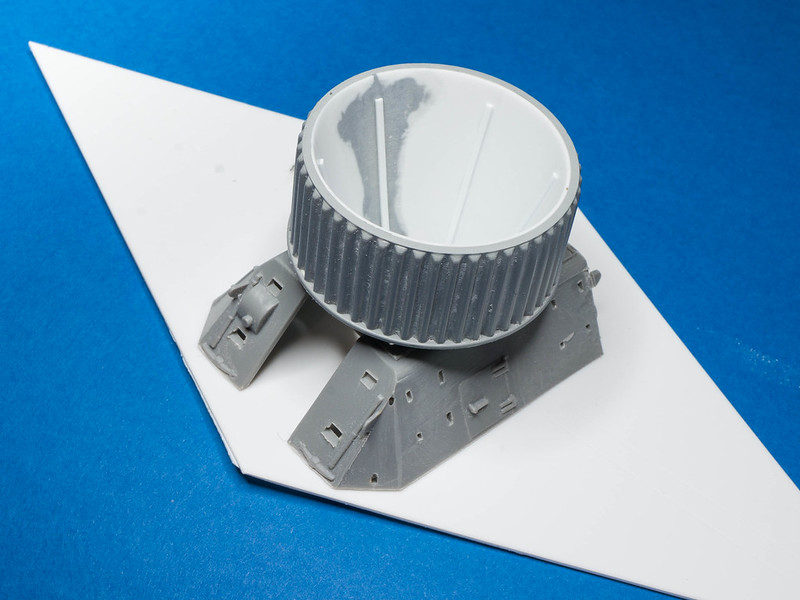

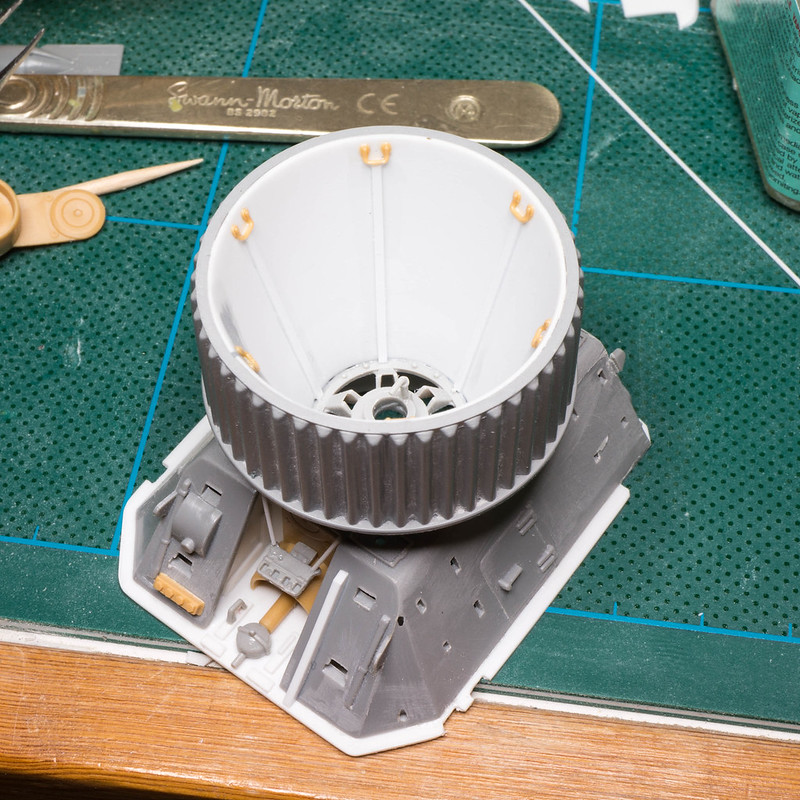

It's cool isn't it? The complete coupler is that thing plus the two light grey screw rings - I think the "teeth" get driven against the hose by the rings when they're screwed down.

The only problem is that a friend suggests it might well be made of polypropylene, which is very very hard to paint and glue. I think a pro would cast it in resin but I don't have any experience with that, so one option would be to use it as a concept and make something similar from styrene.

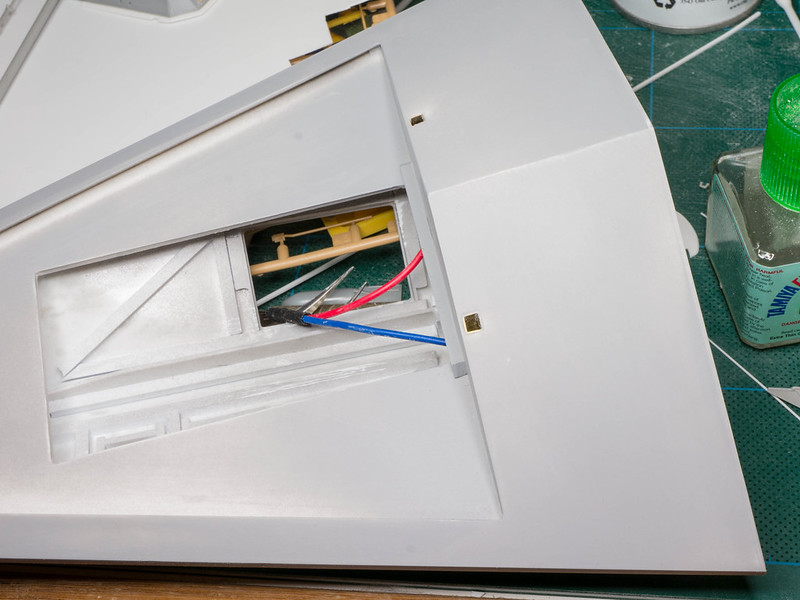

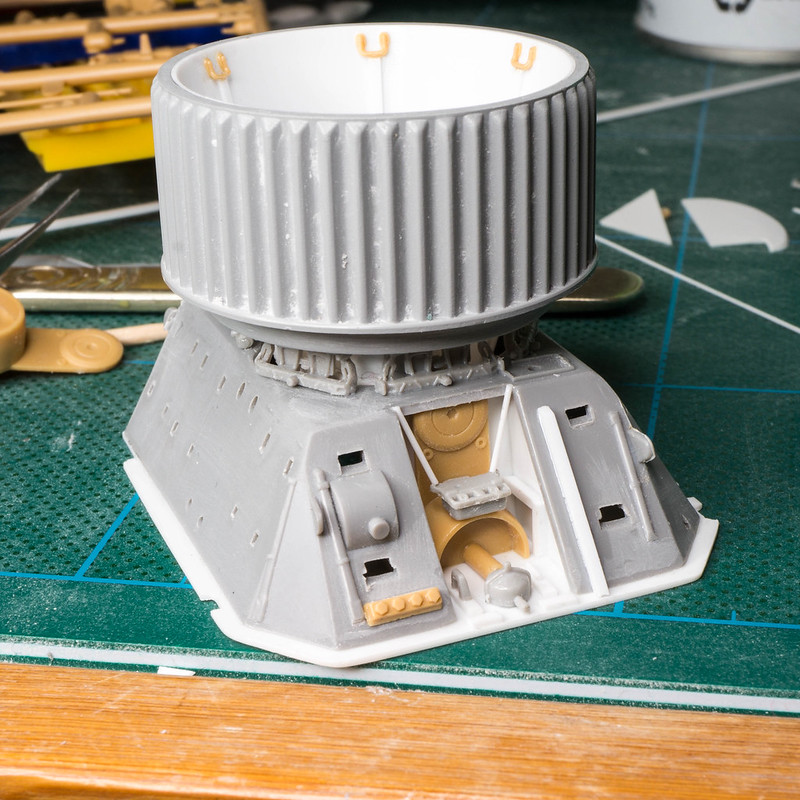

I got two more bits today - a couple of those plastic eggs for silly putty. I'm thinking they might make nice NASA-style engine bells which would look pretty cool. Still playing, really, which is frustrating because I'd like to get the back plate on so that I can detail the hull, but I need to make any engine cut-outs first.

Will

The only problem is that a friend suggests it might well be made of polypropylene, which is very very hard to paint and glue. I think a pro would cast it in resin but I don't have any experience with that, so one option would be to use it as a concept and make something similar from styrene.

I got two more bits today - a couple of those plastic eggs for silly putty. I'm thinking they might make nice NASA-style engine bells which would look pretty cool. Still playing, really, which is frustrating because I'd like to get the back plate on so that I can detail the hull, but I need to make any engine cut-outs first.

Will