dday

Sr Member

Hi all,

I call this build a DVH 2.5 because the cast parts themselves are the V2 from DVH however I've done a bit of build streamlining with a custom pipe, rail and tracks from Sskunky.

I offer these kits for sale in limited runs, see my signature for the sale thread and put up interest in the current or an upcoming run.

Without further ado....

So, I started out thinking I would offer the kits with a PVC pipe, but since the PVC pipes I have easily available are pretty thin walled, when I cut the holes for the ejection port and the cocking lever slide, the PVC decided to collapse a little... Plus who wants PVC when there is a nice aluminum pipe available?

You can't see the warping in this photo very well, I didn't take a good picture of it but it is there.

After giving up on the PVC pipe, and going with the aluminum, I've made up some new group photos with the tracks, d-ring alu pipe and all the parts as shown here.

The PVC experience was very good, I learned a bit about the positioning, how I wanted to attach things and what I could do better on the next round.

I ordered some 38OD 1.5mm wall aluminum pipe, which is pretty close the same ID as the original pipes and is very easily available for me. I'm considering using a 40mm pipe later, since the DVH parts are formed around a 40mm pipe. I will decide after the first wave of these kits are out.

So phase 1 was to use the template at http://www.whitearmor.net/forum/topic/16705-the-best-sterling-templates-ever/page-5 the templates are at the bottom of the page, post #99. There are templates created by our FISD members DaveJ, V7sj, sskunky and Zeroroom and the help of other members in the thread. Big props to them for these, they are amazing.

Now, I had bought a little drill press that you lock your drill into and go and a 10.7mm spiral bit for the barrel holes, it worked great for the PVC pipe, but I rapidly found out this setup was NOT going to cut it for the Aluminum pipe. The bit was too long, so there was not a nice, straight cut and the spiral bits can jam up and splinter or catch the pipe and holes can be misaligned and so on. Also, the press wasn't really smooth enough and robust enough to get the kind of precision I was looking for in the drilling. So I packed it back up and am going to take it back to the store. Luckily I was smart enough to try a few practice holes on a scrap piece of aluminum and not the pipes I want to use for the kits!

To solve both of the previous problems I ordered a larger drill press with the drill built in, adjustable drilling platform and so on. Not a really expensive one, but one good enough to do this job. I also ordered a step bit that will handle the holes and due to it's shape and length will help when being more precise with the holes.

Now... while I wait for that to arrive, I started doing the other stuff I needed to do on the pipe that don't need a nice drill press.

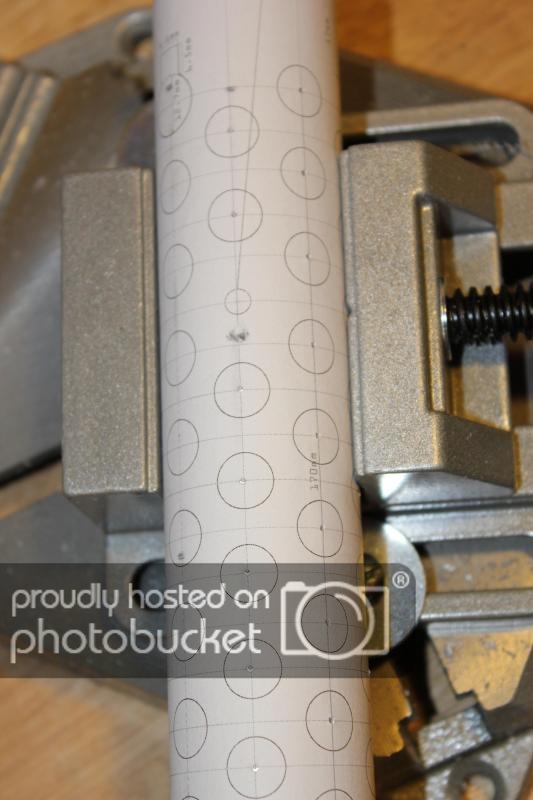

So step one, attach the templates nice and tight and straight.

Then I took my pipe cutter and got the exact right length of pipe.

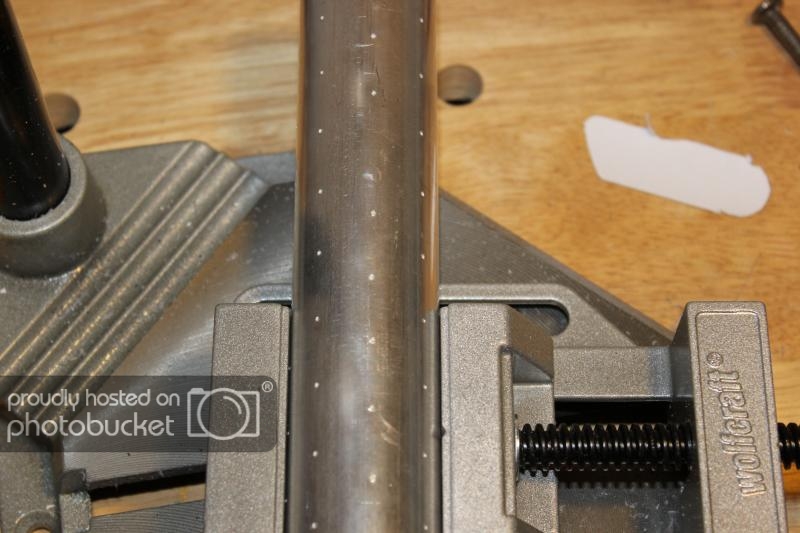

I started out by using a punch (or a big nail) to mark the holes in the pipe for later. Thats a lot of holes... and I did 6 pipes worth of holes.

Once the holes all over the pipe were punched, I took a box cutter and cut out the ejection port, marked where the magazine feeder was, cut out the cocking hammer path and marked where the stock lug attaches on the front.

Once the template was taken off, the punched holes are now visible as well as a nice tracing of where the cut out parts should be.

I drilled a few holes in the ejection port to lessen the amount of metal I had to cut off, then took out the dremel to cut out the rest of the metal... I burned through 2 cutting disks on this, so I might look for another way, but for now... it is what I have to use.

After some more grinding and clean up, I've basically arrived at a point where I'm happy with the cutouts. Next comes attaching the main parts to the pipe. I really want to build it so that these main parts are removable so that in the future of someone wants to add real sterling parts, or electronics (the bolt has a hole for electronics and wiring) it will be a snap.

So the first step is to screw on the magazine feeder (My kits include all the holes predrilled in the pipe and the screws needed to attach everything) to the pipe. It is pretty easy, just take the small short brass screws and screw them into the magazine. The holes in the pipe and magazine receiver are already there in my kits.

The screws shown here were the first version, included in the kits are smaller brass ones that sit flush with the pipe so the bolt doesn't get snagged.

Once this is done, you will put the bolt in, and slide the bolt lever in the large hole at the back into the bolt. Once this is done slide the bolt all the way forward.

The cocking lever is not glued in but rather just sits in the bolt hole. It may wiggle a little but it won't fall out or anything since it is held in by the pipe and the bolt. It might actually save you a broken cocking handle since if it gets snagged there is a little give in it.

Then you put the handle on the bottom and take the two longer brass screws and screw them through the bottom. These go through the handle using the default sterling holes and through the pipe and into the bolt itself. This will hold the handle on tight and keep the bolt in a static location.

Again, this can all be disassembled for any reason any time you want since it's all modular and screwed in rather then glued on.

After getting the new table drill press, I'm very pleased!

I drilled up the first pipe filly today and will be keeping on with the build and shipping the paid for kits this week.

There will be parts the need to be glued onto the pipe as screwing them on will not be a good way to go, but as I progress, you will see which they are...

Ok, updates and a photogasm.

I would have kept on working on it except the camera battery died and I can't take progress photos if the good camera doesn't have a loaded battery!

Here are some overview shots of the main pieces screwed on. Once I started adding the other pieces, I have removed these pieces to put on later.

Here, I cut out the stuff on the inside so that I had the frame and the center block (for the sight) and glued them on separately. As well as glueing in the nose. Since the kit was built for a 40mm tube, I had to shave off the edge a bit to make it fit and look better.

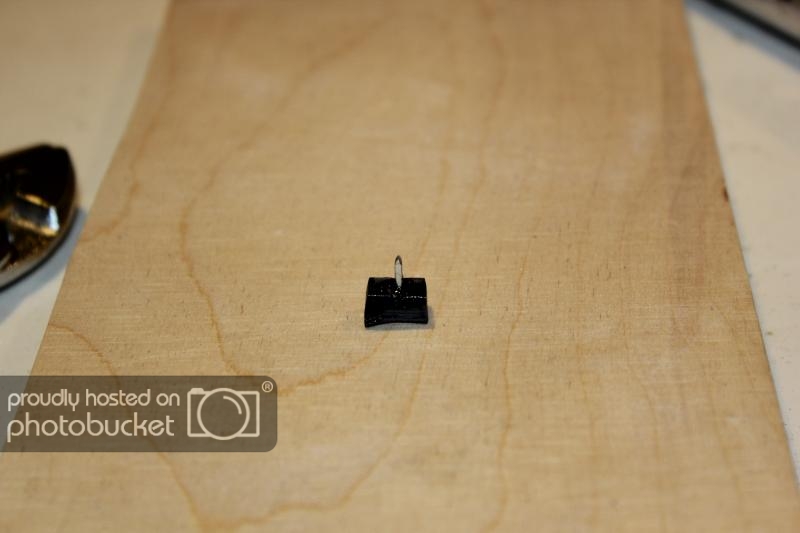

To make the front sight needle I took the nail from a pop rivet and ground the roundness out of the last 5mm of it so it was more flat on each side.

Chopped it off and drilled a small hole in the sight block and glued it in there.

To screw on the bayonet lug, you stick the screwdriver through the other side and screw it down.

The folding stock is next up. I put holes in the sides with a small drill bit through the stock and the stock mount. Then I screwed in two short screws to hold it in place. It's not accurate, as here was a domed pin in the originals.

Now to attach the stock handle to the stock itself. I like adding pins into high stress pieces like this, just glueing it is asking for trouble with such a heavy piece.

Ok, updates and a photogasm.

I would have kept on working on it except the camera battery died and I can't take progress photos if the good camera doesn't have a loaded battery!

Here are some overview shots of the main pieces screwed on. Once I started adding the other pieces, I have removed these pieces to put on later.

Here, I cut out the stuff on the inside so that I had the frame and the center block (for the sight) and glued them on separately. As well as glueing in the nose. Since the kit was built for a 40mm tube, I had to shave off the edge a bit to make it fit and look better.

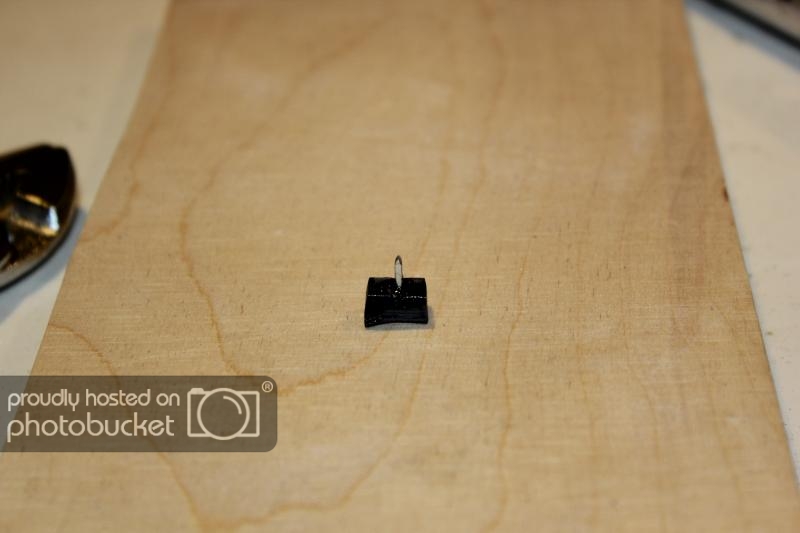

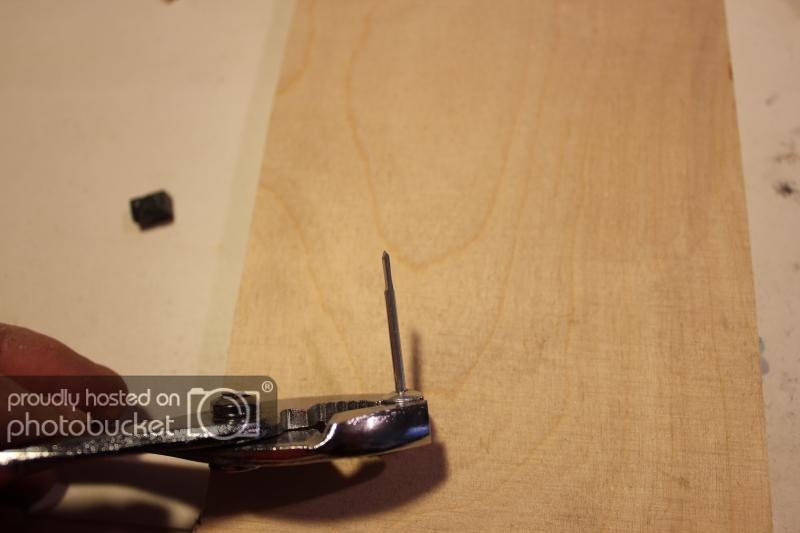

To make the front sight needle I took the nail from a pop rivet and ground the roundness out of the last 5mm of it so it was more flat on each side.

Chopped it off and drilled a small hole in the sight block and glued it in there.

To screw on the bayonet lug, you stick the screwdriver through the other side and screw it down.

The folding stock is next up. I put holes in the sides with a small drill bit through the stock and the stock mount. Then I screwed in two short screws to hold it in place. It's not accurate, as here was a domed pin in the originals.

Now, to attach the stock handle to the stock itself. I like adding pins to high stress/heavy pieces like this. If you don't you're really asking for trouble and repairs later on. I use the shaft of a pop rivet for this, they are great axles and pins.

Simple drill a hole in one side, put some glue on the pin, stick it in.

Then find out where the pin touches on the opposite side and drill a new hole there. Add some glue to the pin and the contacting resin and put it together.

This is the whole thing in one piece.

This is easy enough. Just shape the port guard so it sits on the pipe well. Add the glue, attach it and hold a few seconds.

The front one is the same. Just make sure you face it the right way. It should be opposite the way you have the ejection port guard.

The scope rail is quickly finished as well. You'll need approx. 26cm of the aluminum bar. Then you'll shape it roughly like you see here.

The nose is to hold the rail in place once the back is screwed down. If you add this nose to it, it won't move or come out.

The end will look similar to this and will bolt through the rail, the rear sight and the tube. You'll have to drill this hole in the tube, I didn't put it in there because it might vary based on how you cut the rail and how you want to attach it. A simple house drill and bit will do this, Aluminum is easy to drill.

Now, when the camera battery is charged, more photos and building!

I am very close to finished. Tomorrow I will check the final pieces and ensure they are secure on the tube. After this I will take all the removable parts off and paint them in groups. This will make the painting job go easier all of the hard corners and tight spaces will be opened by separating the pieces for painting.

Camera Battery back up, the attachment for the back of the rail. Simply bolted through the rail to the sight and a nut on the inside of the tube.

All Front parts attached.

The 2 knobs/tensioners added to the mag housing

The folding stock clip on the bottom

The mag housing and the mag needed some grinding on to get them to match up well. Then I drilled in 2 pins to help it stay in place and align right.

Dropped on the powercells/targeting thingies

Trigger glues in

Trigger guard in. If you add this now you will have to grind some in order to get the screw in the front. If I did it again, I would keep the trigger guard separate until after painting and all was assembled, then glue it in.

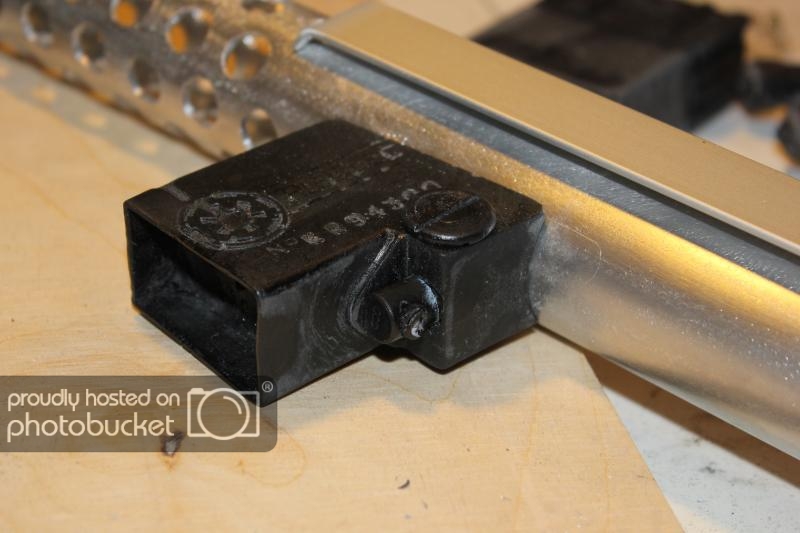

This bolt head drops right in and screws in tight.

Bolts in the front need glue to stay in.

After sitting down and thinking about attaching the hengstler rail, I realized how dumb it is to try and attach it with the extra from the scope rail. So I grabbed some L aluminum I had around and cut out a bracket. Then I drilled in all the holes for the screws.

I decided I wanted the L to point up (vs the common down) so I will always know my build no matter where it goes!

So the blaster almost in it's final state. I discovered that the CA (super)glue doesn't work well on it's own for the pieces connected to the aluminum. It is good enough for sticking it on, but it will be knocked off easily. So I decided to try out some CA glue in one spot to hold it down and E6000 on the rest of the piece to see what kind of a grip it will have. The tape over the pieces is part of that, to hold the piece tight. I also scored into the aluminum more where I glued to give the glue more to grip onto.

I am pretty sure I will add the T-Tracks as the final piece after painting. I'm not sure if the tracks on the blasters were painted at all, or just attached. Once everything is painted, I will see how they look unpainted, but if the colors stand out too much, I will sand them down some and paint it the same as the rest.

So, the final steps revealed!

I realized that I didn't feel good about just glueing the folding stock on. It is one of the heaviest pieces, so I decided to glue it on.

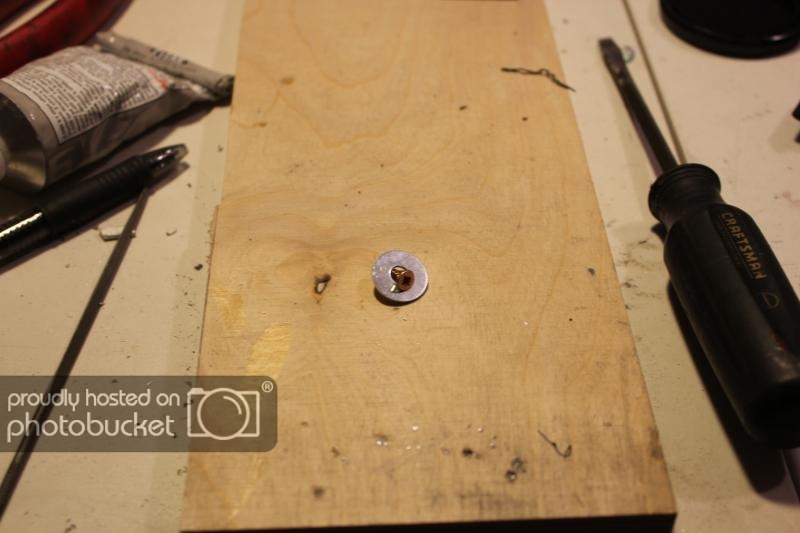

I used a small screw with a washer, since the hole was drilled and the screw alone wasn't enough.

Screw it in from the top row of holes into a predrilled hole on the thick part of the stock.

Now this was sorted, the sun had come out so it's time to get some paint on!

Bending the T-Tracks was interesting. to do it, I drilled a hole in a wood 2x4 and used this edge to fold it down once heated with a heat gun. Be aware, heatguns heat the plastic very fast! If you aren't careful the structure of the track will collapse, warm, melt and many other terrible things. So heat it slowly and carefully just until it is able to be shaped with a little pressure. Leave the very top track off for this moment.

I got the tracks to fit in the best and lay flat when I pointed the ends straight down. If the tracks are slanted at an angle on the ends, it naturally will want to bow up in the middle.

After the tracks are fitted in there good (add some glue to the edges where they go into the holes if they aren't fitting in tight and moving around some). and before you glue in the end cap lock, you'll want to mount the folding stock. Pass the screw and washer through the end of the tube and screw it down. You will need to have the bolt out for the washer to fit through as well.

Now you have to glue the endcap lock in and glue the D-ring cap on the end cap. Make sure you fit the endcap on the lock first and find out the right positioning so it sits straight.

Now you're done.

Here is the finished E11. I've weathered it with dry brushing on some silver and then chipping off some of the paint on the aluminum parts. Just remember, the tracks are not metal, so no battle damage on these. The scope is brass under, so if you weather this, use a copper or a copperish brown.

Adding the spring is such a cinch, so I just did it.

No photos, but it's easy. You take a wire hanger.... I had an uncoated, unpainted standard silver one (which is best)... and straightened it out with a pair of plyers. Then I took and wrapped it around a broom handle. Once it was done, I took it off and fixed the spacing with my fingers and viola! Done.

I was inadvertently lucky though, the bolt I used to hold the read right and rail on sticks inside the tube a little. This actually acted as a threading point for the new spring. The wire turned in based on this point and this will also help keep it steady and not rattle on the inside or move.

I call this build a DVH 2.5 because the cast parts themselves are the V2 from DVH however I've done a bit of build streamlining with a custom pipe, rail and tracks from Sskunky.

I offer these kits for sale in limited runs, see my signature for the sale thread and put up interest in the current or an upcoming run.

Without further ado....

So, I started out thinking I would offer the kits with a PVC pipe, but since the PVC pipes I have easily available are pretty thin walled, when I cut the holes for the ejection port and the cocking lever slide, the PVC decided to collapse a little... Plus who wants PVC when there is a nice aluminum pipe available?

You can't see the warping in this photo very well, I didn't take a good picture of it but it is there.

After giving up on the PVC pipe, and going with the aluminum, I've made up some new group photos with the tracks, d-ring alu pipe and all the parts as shown here.

The PVC experience was very good, I learned a bit about the positioning, how I wanted to attach things and what I could do better on the next round.

I ordered some 38OD 1.5mm wall aluminum pipe, which is pretty close the same ID as the original pipes and is very easily available for me. I'm considering using a 40mm pipe later, since the DVH parts are formed around a 40mm pipe. I will decide after the first wave of these kits are out.

So phase 1 was to use the template at http://www.whitearmor.net/forum/topic/16705-the-best-sterling-templates-ever/page-5 the templates are at the bottom of the page, post #99. There are templates created by our FISD members DaveJ, V7sj, sskunky and Zeroroom and the help of other members in the thread. Big props to them for these, they are amazing.

Now, I had bought a little drill press that you lock your drill into and go and a 10.7mm spiral bit for the barrel holes, it worked great for the PVC pipe, but I rapidly found out this setup was NOT going to cut it for the Aluminum pipe. The bit was too long, so there was not a nice, straight cut and the spiral bits can jam up and splinter or catch the pipe and holes can be misaligned and so on. Also, the press wasn't really smooth enough and robust enough to get the kind of precision I was looking for in the drilling. So I packed it back up and am going to take it back to the store. Luckily I was smart enough to try a few practice holes on a scrap piece of aluminum and not the pipes I want to use for the kits!

To solve both of the previous problems I ordered a larger drill press with the drill built in, adjustable drilling platform and so on. Not a really expensive one, but one good enough to do this job. I also ordered a step bit that will handle the holes and due to it's shape and length will help when being more precise with the holes.

Now... while I wait for that to arrive, I started doing the other stuff I needed to do on the pipe that don't need a nice drill press.

So step one, attach the templates nice and tight and straight.

Then I took my pipe cutter and got the exact right length of pipe.

I started out by using a punch (or a big nail) to mark the holes in the pipe for later. Thats a lot of holes... and I did 6 pipes worth of holes.

Once the holes all over the pipe were punched, I took a box cutter and cut out the ejection port, marked where the magazine feeder was, cut out the cocking hammer path and marked where the stock lug attaches on the front.

Once the template was taken off, the punched holes are now visible as well as a nice tracing of where the cut out parts should be.

I drilled a few holes in the ejection port to lessen the amount of metal I had to cut off, then took out the dremel to cut out the rest of the metal... I burned through 2 cutting disks on this, so I might look for another way, but for now... it is what I have to use.

After some more grinding and clean up, I've basically arrived at a point where I'm happy with the cutouts. Next comes attaching the main parts to the pipe. I really want to build it so that these main parts are removable so that in the future of someone wants to add real sterling parts, or electronics (the bolt has a hole for electronics and wiring) it will be a snap.

So the first step is to screw on the magazine feeder (My kits include all the holes predrilled in the pipe and the screws needed to attach everything) to the pipe. It is pretty easy, just take the small short brass screws and screw them into the magazine. The holes in the pipe and magazine receiver are already there in my kits.

The screws shown here were the first version, included in the kits are smaller brass ones that sit flush with the pipe so the bolt doesn't get snagged.

Once this is done, you will put the bolt in, and slide the bolt lever in the large hole at the back into the bolt. Once this is done slide the bolt all the way forward.

The cocking lever is not glued in but rather just sits in the bolt hole. It may wiggle a little but it won't fall out or anything since it is held in by the pipe and the bolt. It might actually save you a broken cocking handle since if it gets snagged there is a little give in it.

Then you put the handle on the bottom and take the two longer brass screws and screw them through the bottom. These go through the handle using the default sterling holes and through the pipe and into the bolt itself. This will hold the handle on tight and keep the bolt in a static location.

Again, this can all be disassembled for any reason any time you want since it's all modular and screwed in rather then glued on.

After getting the new table drill press, I'm very pleased!

I drilled up the first pipe filly today and will be keeping on with the build and shipping the paid for kits this week.

There will be parts the need to be glued onto the pipe as screwing them on will not be a good way to go, but as I progress, you will see which they are...

Ok, updates and a photogasm.

I would have kept on working on it except the camera battery died and I can't take progress photos if the good camera doesn't have a loaded battery!

Here are some overview shots of the main pieces screwed on. Once I started adding the other pieces, I have removed these pieces to put on later.

Here, I cut out the stuff on the inside so that I had the frame and the center block (for the sight) and glued them on separately. As well as glueing in the nose. Since the kit was built for a 40mm tube, I had to shave off the edge a bit to make it fit and look better.

To make the front sight needle I took the nail from a pop rivet and ground the roundness out of the last 5mm of it so it was more flat on each side.

Chopped it off and drilled a small hole in the sight block and glued it in there.

To screw on the bayonet lug, you stick the screwdriver through the other side and screw it down.

The folding stock is next up. I put holes in the sides with a small drill bit through the stock and the stock mount. Then I screwed in two short screws to hold it in place. It's not accurate, as here was a domed pin in the originals.

Now to attach the stock handle to the stock itself. I like adding pins into high stress pieces like this, just glueing it is asking for trouble with such a heavy piece.

Ok, updates and a photogasm.

I would have kept on working on it except the camera battery died and I can't take progress photos if the good camera doesn't have a loaded battery!

Here are some overview shots of the main pieces screwed on. Once I started adding the other pieces, I have removed these pieces to put on later.

Here, I cut out the stuff on the inside so that I had the frame and the center block (for the sight) and glued them on separately. As well as glueing in the nose. Since the kit was built for a 40mm tube, I had to shave off the edge a bit to make it fit and look better.

To make the front sight needle I took the nail from a pop rivet and ground the roundness out of the last 5mm of it so it was more flat on each side.

Chopped it off and drilled a small hole in the sight block and glued it in there.

To screw on the bayonet lug, you stick the screwdriver through the other side and screw it down.

The folding stock is next up. I put holes in the sides with a small drill bit through the stock and the stock mount. Then I screwed in two short screws to hold it in place. It's not accurate, as here was a domed pin in the originals.

Now, to attach the stock handle to the stock itself. I like adding pins to high stress/heavy pieces like this. If you don't you're really asking for trouble and repairs later on. I use the shaft of a pop rivet for this, they are great axles and pins.

Simple drill a hole in one side, put some glue on the pin, stick it in.

Then find out where the pin touches on the opposite side and drill a new hole there. Add some glue to the pin and the contacting resin and put it together.

This is the whole thing in one piece.

This is easy enough. Just shape the port guard so it sits on the pipe well. Add the glue, attach it and hold a few seconds.

The front one is the same. Just make sure you face it the right way. It should be opposite the way you have the ejection port guard.

The scope rail is quickly finished as well. You'll need approx. 26cm of the aluminum bar. Then you'll shape it roughly like you see here.

The nose is to hold the rail in place once the back is screwed down. If you add this nose to it, it won't move or come out.

The end will look similar to this and will bolt through the rail, the rear sight and the tube. You'll have to drill this hole in the tube, I didn't put it in there because it might vary based on how you cut the rail and how you want to attach it. A simple house drill and bit will do this, Aluminum is easy to drill.

Now, when the camera battery is charged, more photos and building!

I am very close to finished. Tomorrow I will check the final pieces and ensure they are secure on the tube. After this I will take all the removable parts off and paint them in groups. This will make the painting job go easier all of the hard corners and tight spaces will be opened by separating the pieces for painting.

Camera Battery back up, the attachment for the back of the rail. Simply bolted through the rail to the sight and a nut on the inside of the tube.

All Front parts attached.

The 2 knobs/tensioners added to the mag housing

The folding stock clip on the bottom

The mag housing and the mag needed some grinding on to get them to match up well. Then I drilled in 2 pins to help it stay in place and align right.

Dropped on the powercells/targeting thingies

Trigger glues in

Trigger guard in. If you add this now you will have to grind some in order to get the screw in the front. If I did it again, I would keep the trigger guard separate until after painting and all was assembled, then glue it in.

This bolt head drops right in and screws in tight.

Bolts in the front need glue to stay in.

After sitting down and thinking about attaching the hengstler rail, I realized how dumb it is to try and attach it with the extra from the scope rail. So I grabbed some L aluminum I had around and cut out a bracket. Then I drilled in all the holes for the screws.

I decided I wanted the L to point up (vs the common down) so I will always know my build no matter where it goes!

So the blaster almost in it's final state. I discovered that the CA (super)glue doesn't work well on it's own for the pieces connected to the aluminum. It is good enough for sticking it on, but it will be knocked off easily. So I decided to try out some CA glue in one spot to hold it down and E6000 on the rest of the piece to see what kind of a grip it will have. The tape over the pieces is part of that, to hold the piece tight. I also scored into the aluminum more where I glued to give the glue more to grip onto.

I am pretty sure I will add the T-Tracks as the final piece after painting. I'm not sure if the tracks on the blasters were painted at all, or just attached. Once everything is painted, I will see how they look unpainted, but if the colors stand out too much, I will sand them down some and paint it the same as the rest.

So, the final steps revealed!

I realized that I didn't feel good about just glueing the folding stock on. It is one of the heaviest pieces, so I decided to glue it on.

I used a small screw with a washer, since the hole was drilled and the screw alone wasn't enough.

Screw it in from the top row of holes into a predrilled hole on the thick part of the stock.

Now this was sorted, the sun had come out so it's time to get some paint on!

Bending the T-Tracks was interesting. to do it, I drilled a hole in a wood 2x4 and used this edge to fold it down once heated with a heat gun. Be aware, heatguns heat the plastic very fast! If you aren't careful the structure of the track will collapse, warm, melt and many other terrible things. So heat it slowly and carefully just until it is able to be shaped with a little pressure. Leave the very top track off for this moment.

I got the tracks to fit in the best and lay flat when I pointed the ends straight down. If the tracks are slanted at an angle on the ends, it naturally will want to bow up in the middle.

After the tracks are fitted in there good (add some glue to the edges where they go into the holes if they aren't fitting in tight and moving around some). and before you glue in the end cap lock, you'll want to mount the folding stock. Pass the screw and washer through the end of the tube and screw it down. You will need to have the bolt out for the washer to fit through as well.

Now you have to glue the endcap lock in and glue the D-ring cap on the end cap. Make sure you fit the endcap on the lock first and find out the right positioning so it sits straight.

Now you're done.

Here is the finished E11. I've weathered it with dry brushing on some silver and then chipping off some of the paint on the aluminum parts. Just remember, the tracks are not metal, so no battle damage on these. The scope is brass under, so if you weather this, use a copper or a copperish brown.

Adding the spring is such a cinch, so I just did it.

No photos, but it's easy. You take a wire hanger.... I had an uncoated, unpainted standard silver one (which is best)... and straightened it out with a pair of plyers. Then I took and wrapped it around a broom handle. Once it was done, I took it off and fixed the spacing with my fingers and viola! Done.

I was inadvertently lucky though, the bolt I used to hold the read right and rail on sticks inside the tube a little. This actually acted as a threading point for the new spring. The wire turned in based on this point and this will also help keep it steady and not rattle on the inside or move.

Last edited by a moderator: