Tatsutetsu

Member

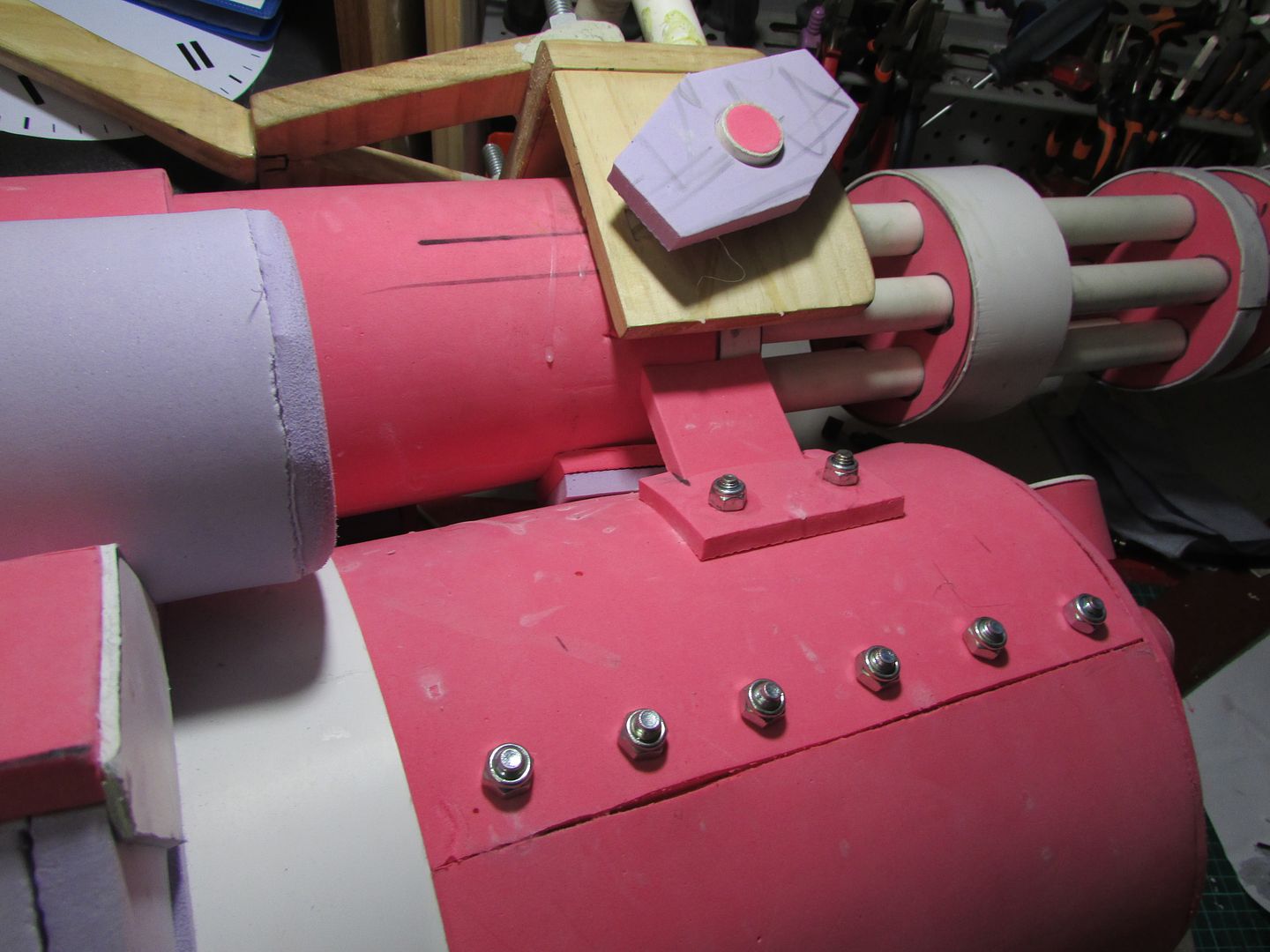

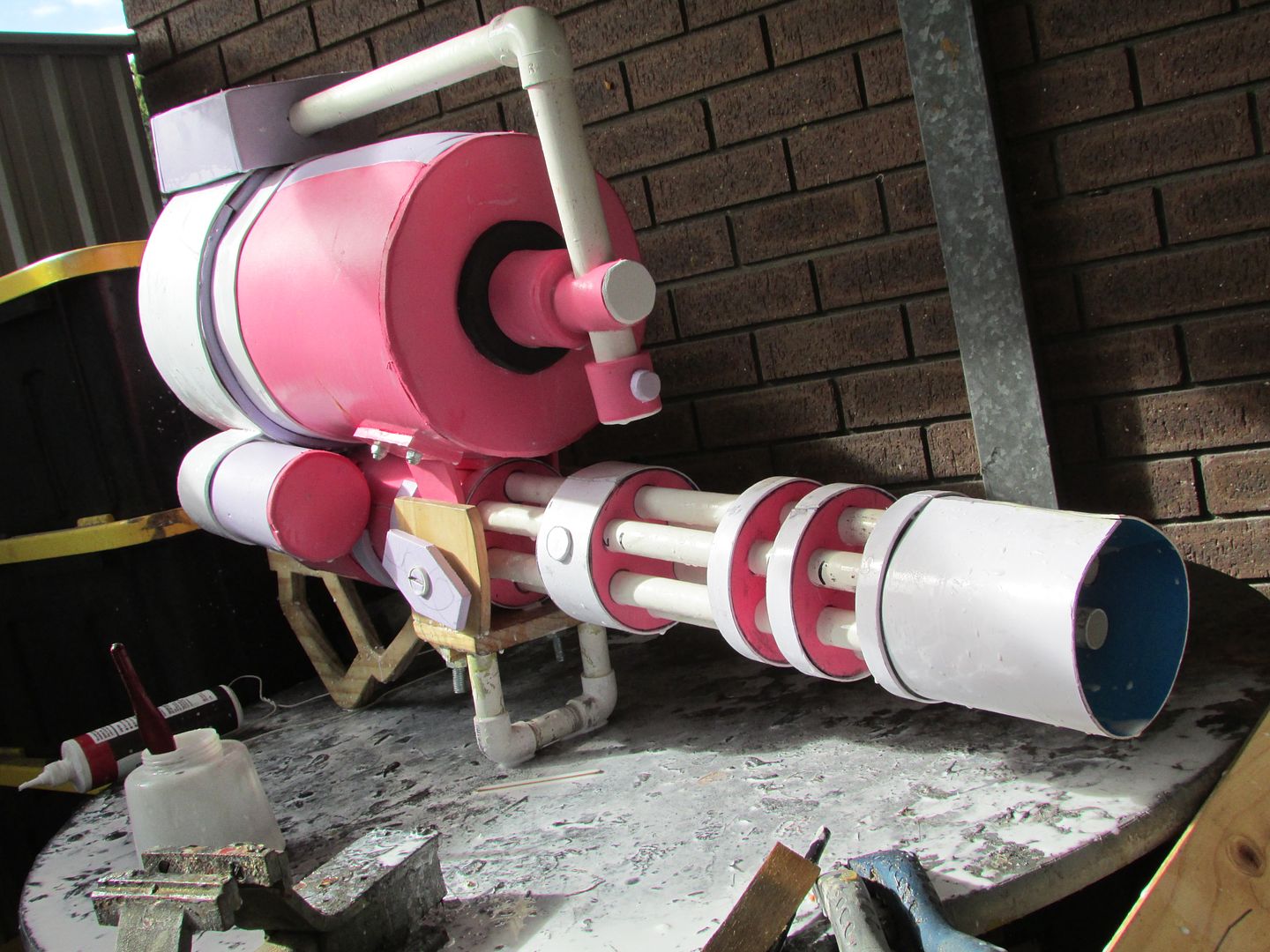

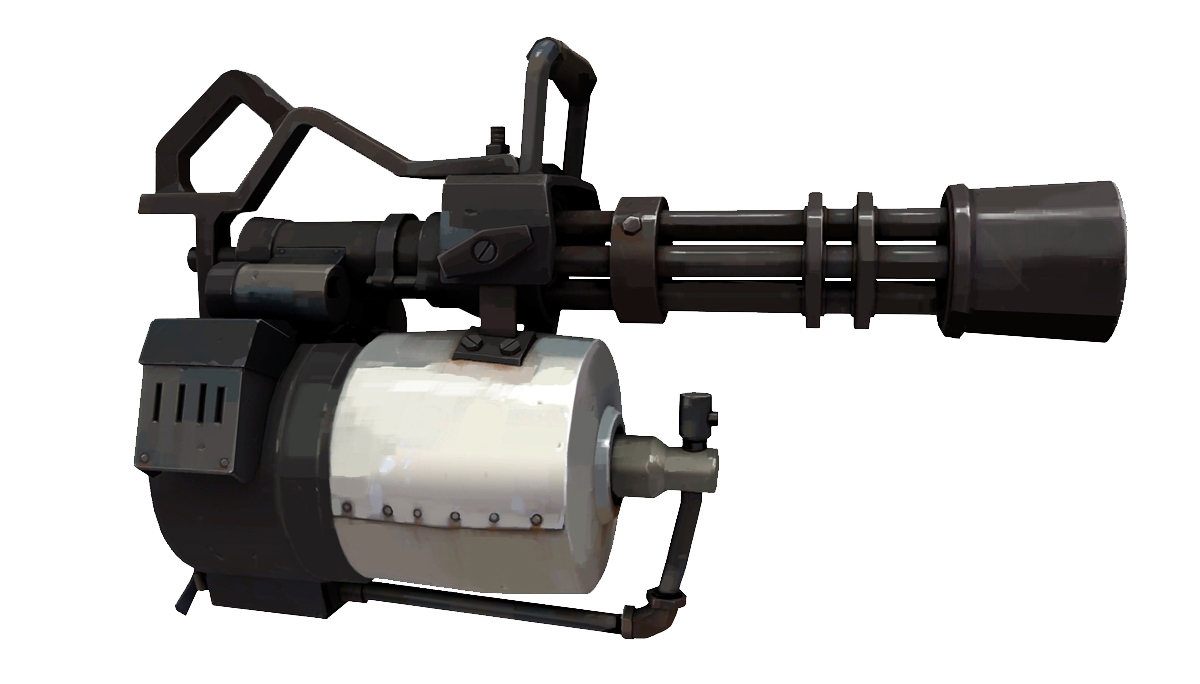

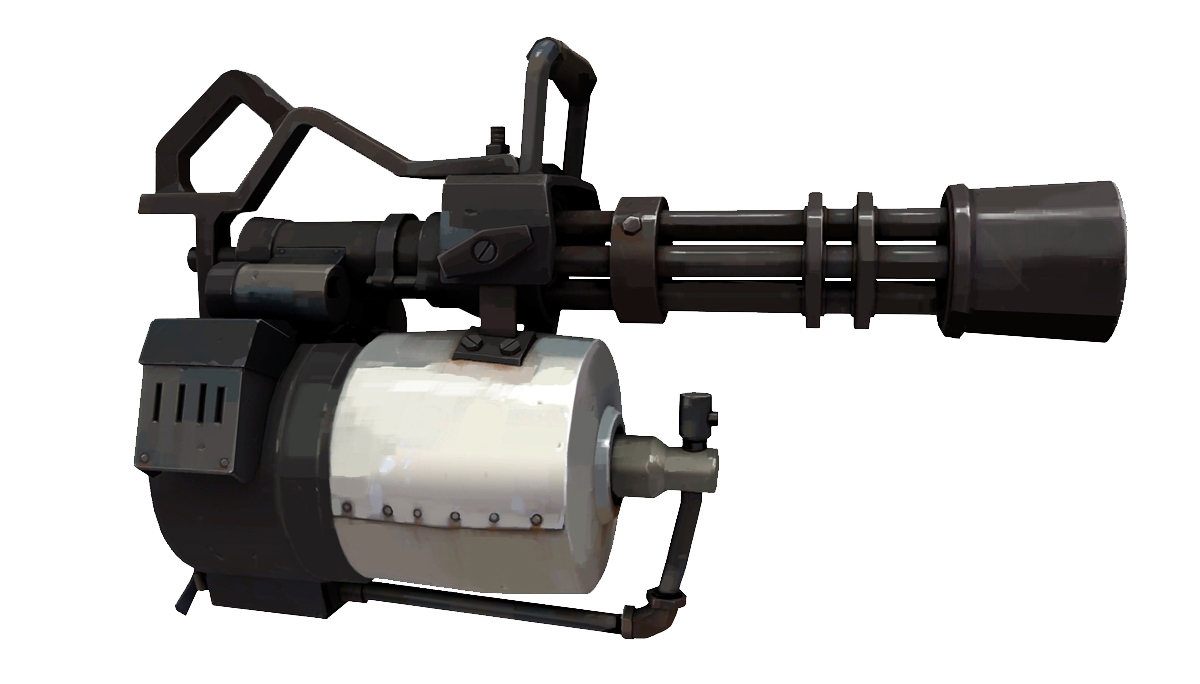

I figured I’d share my progress on the Heavy’s minigun “Sasha” from Team Fortress 2, that I’m currently cranking out for an upcoming convention, that I hope you fellow TF2 fans out there will enjoy.

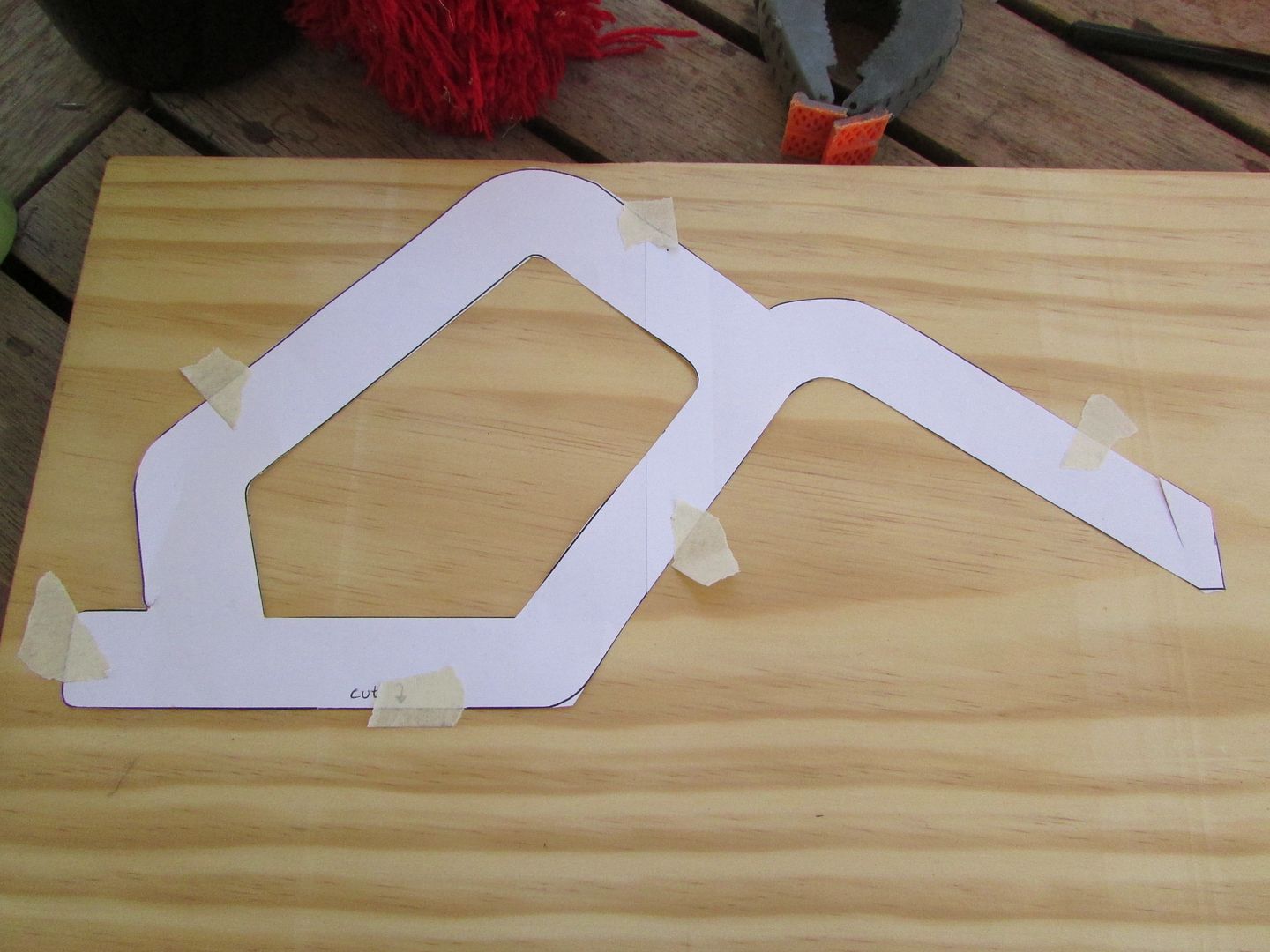

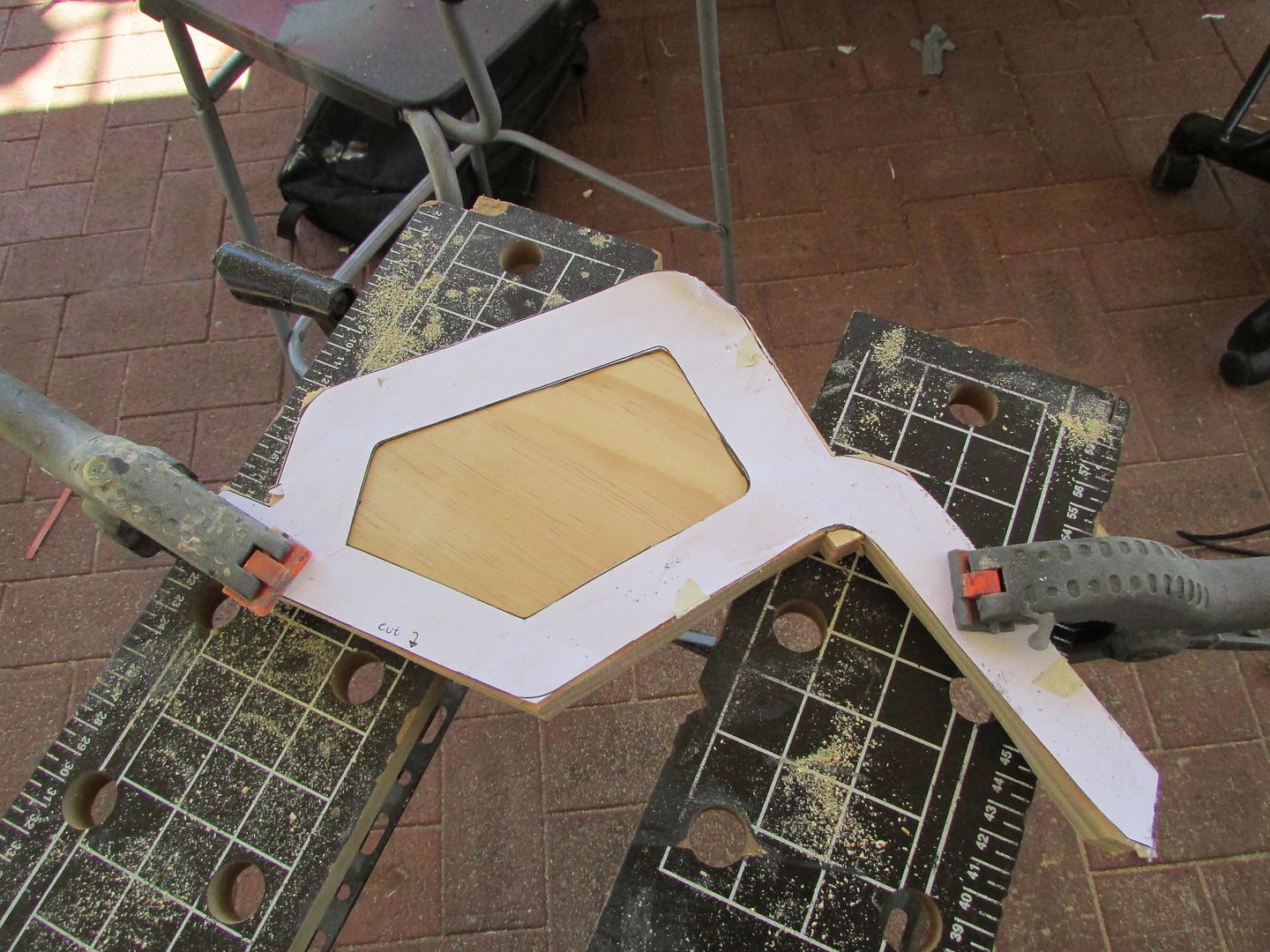

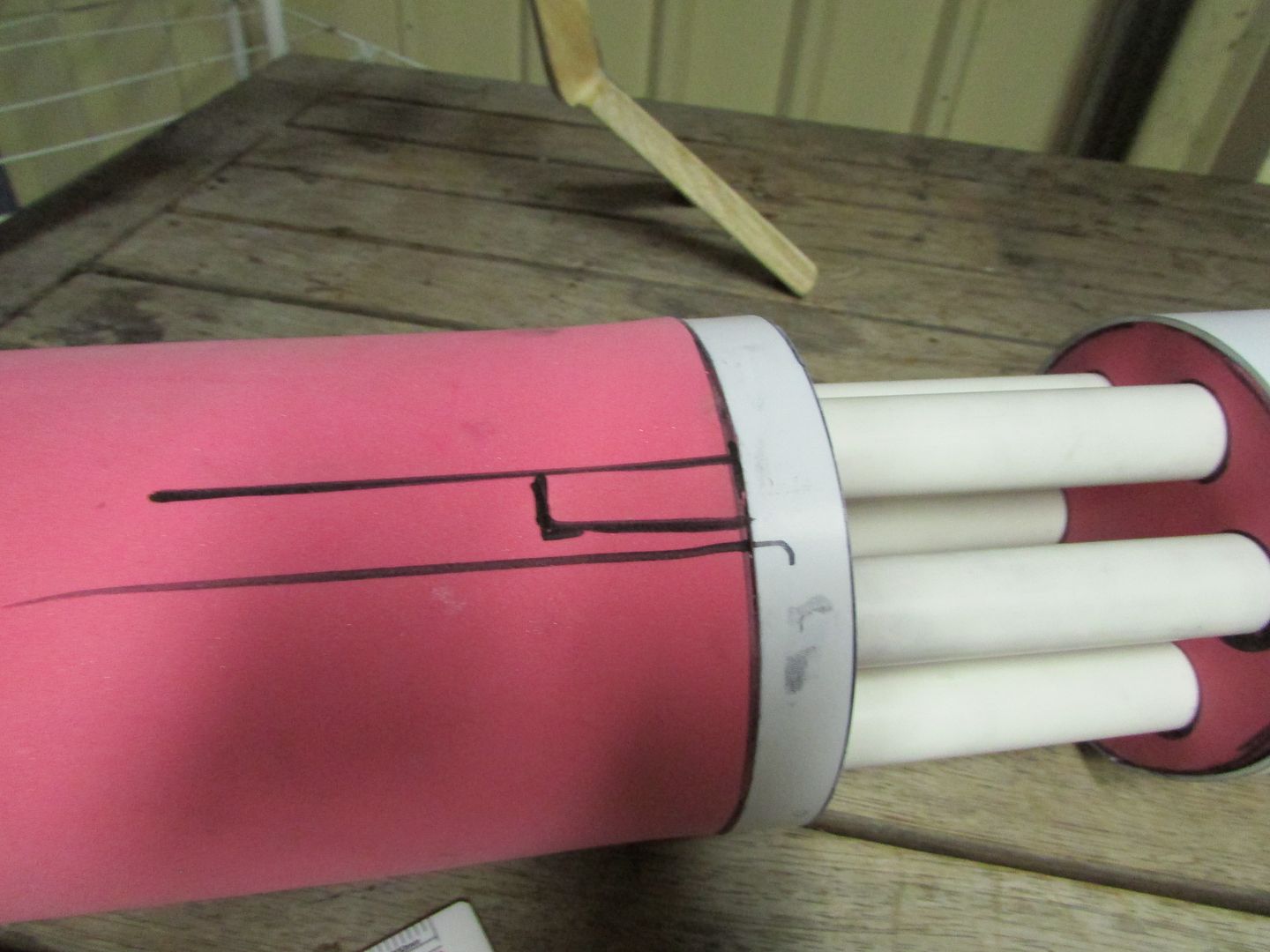

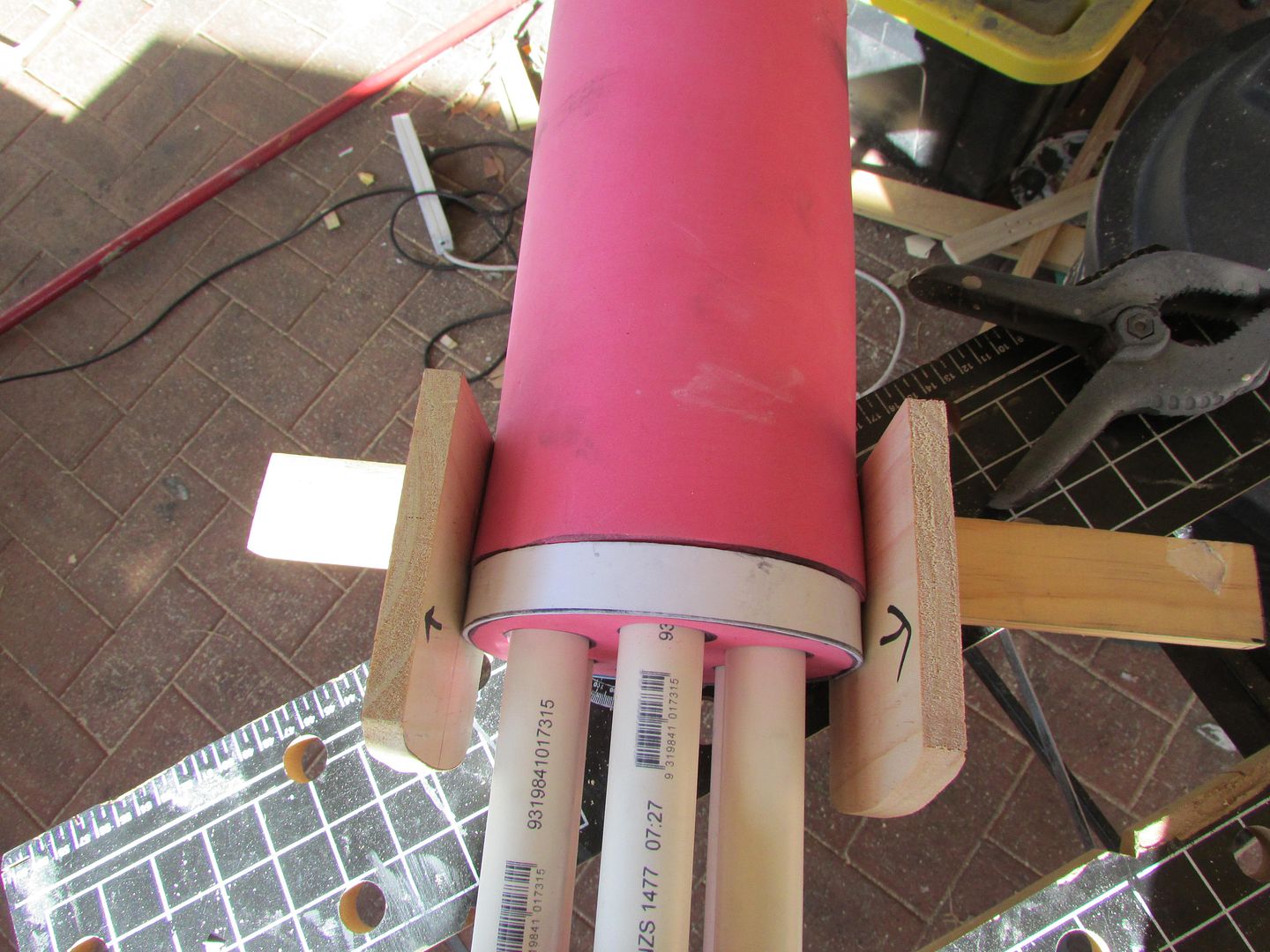

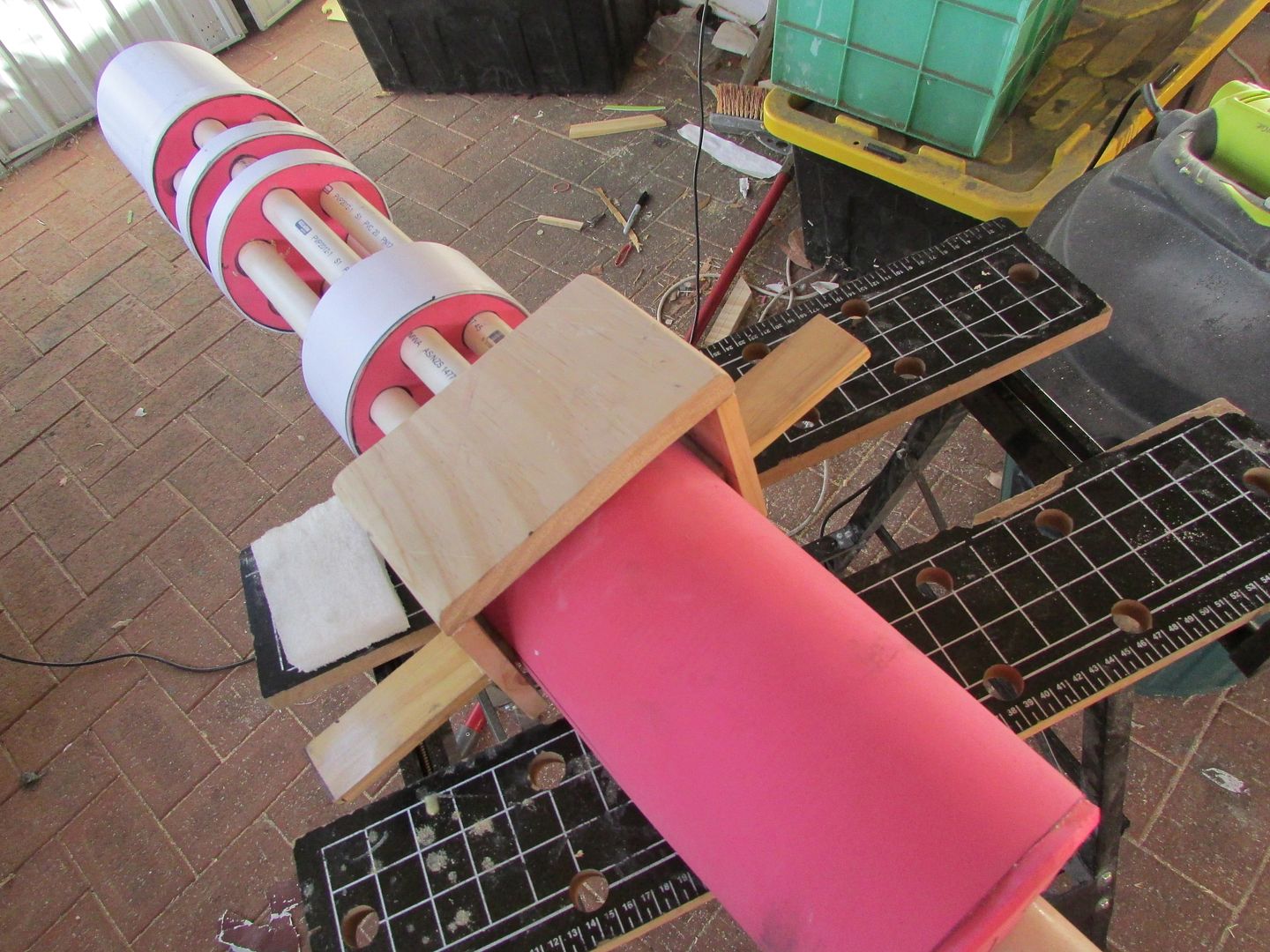

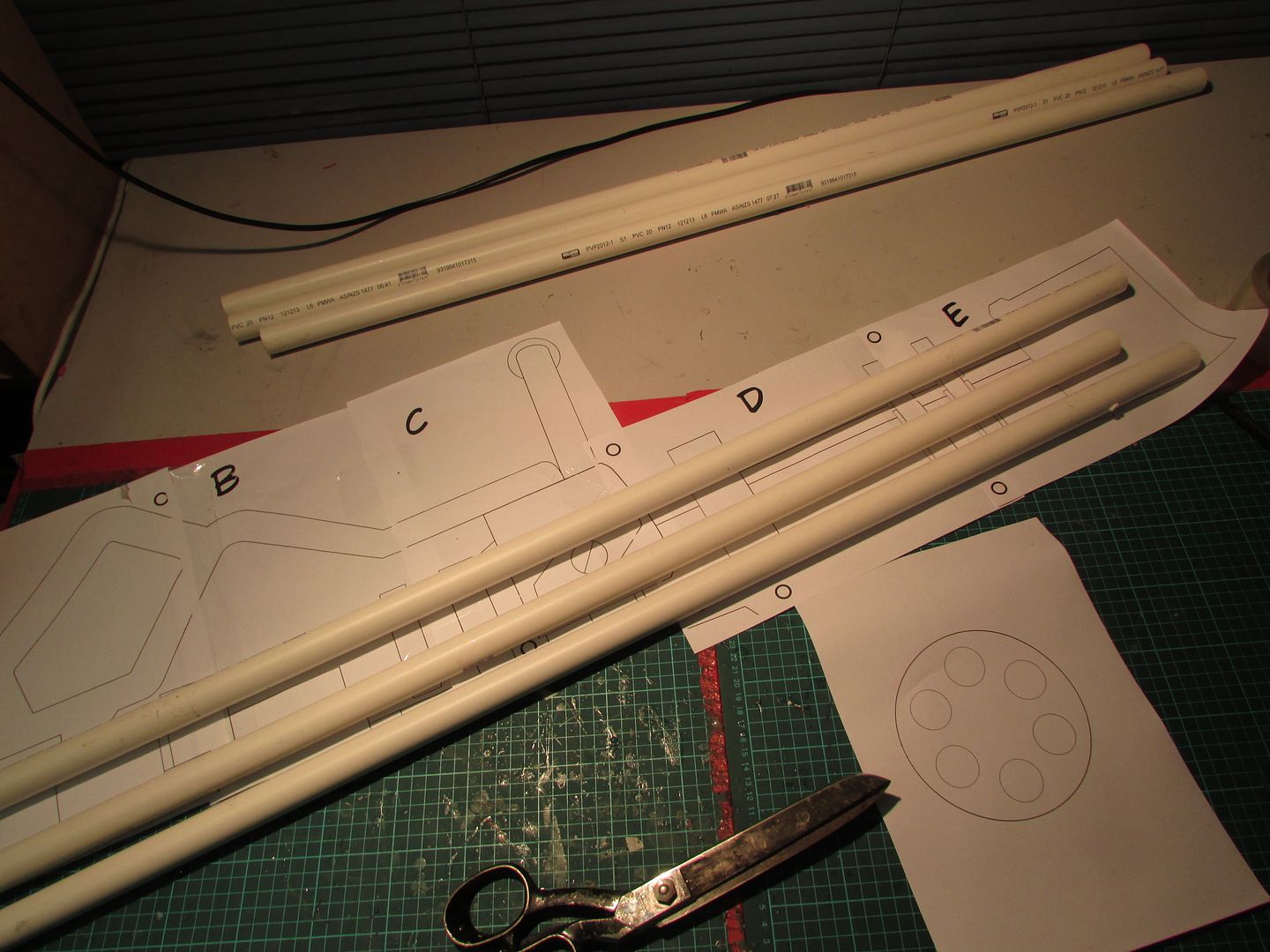

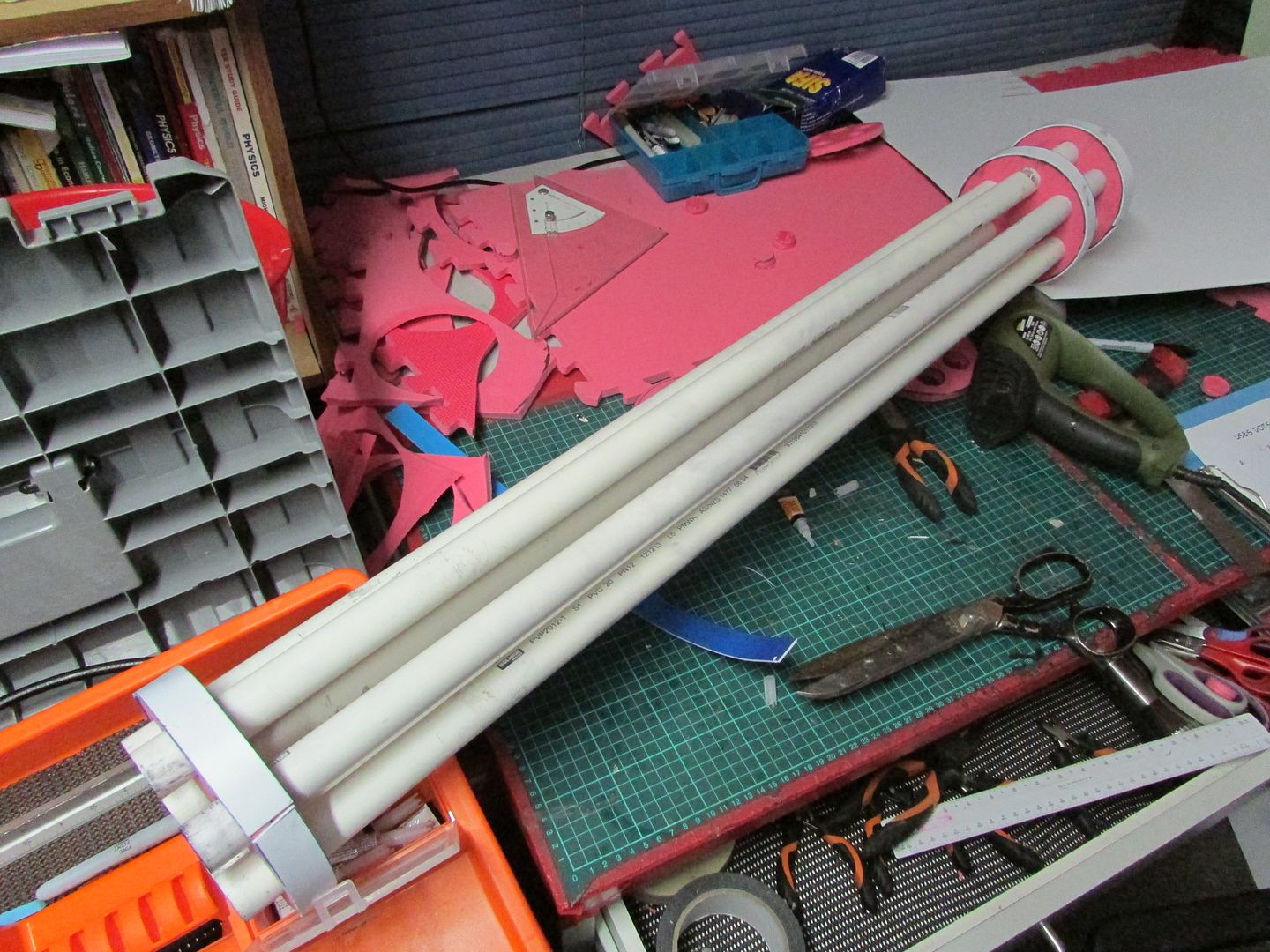

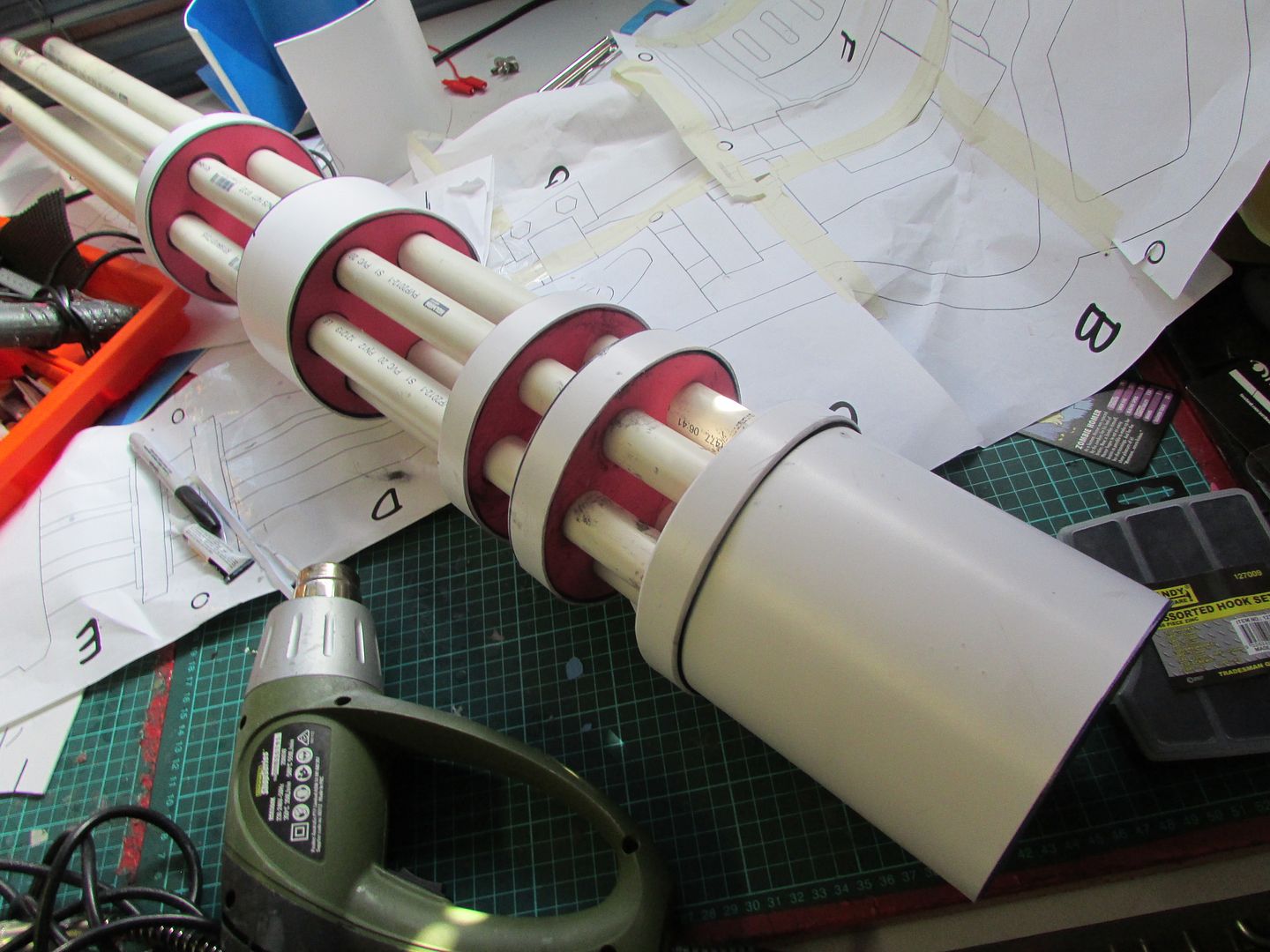

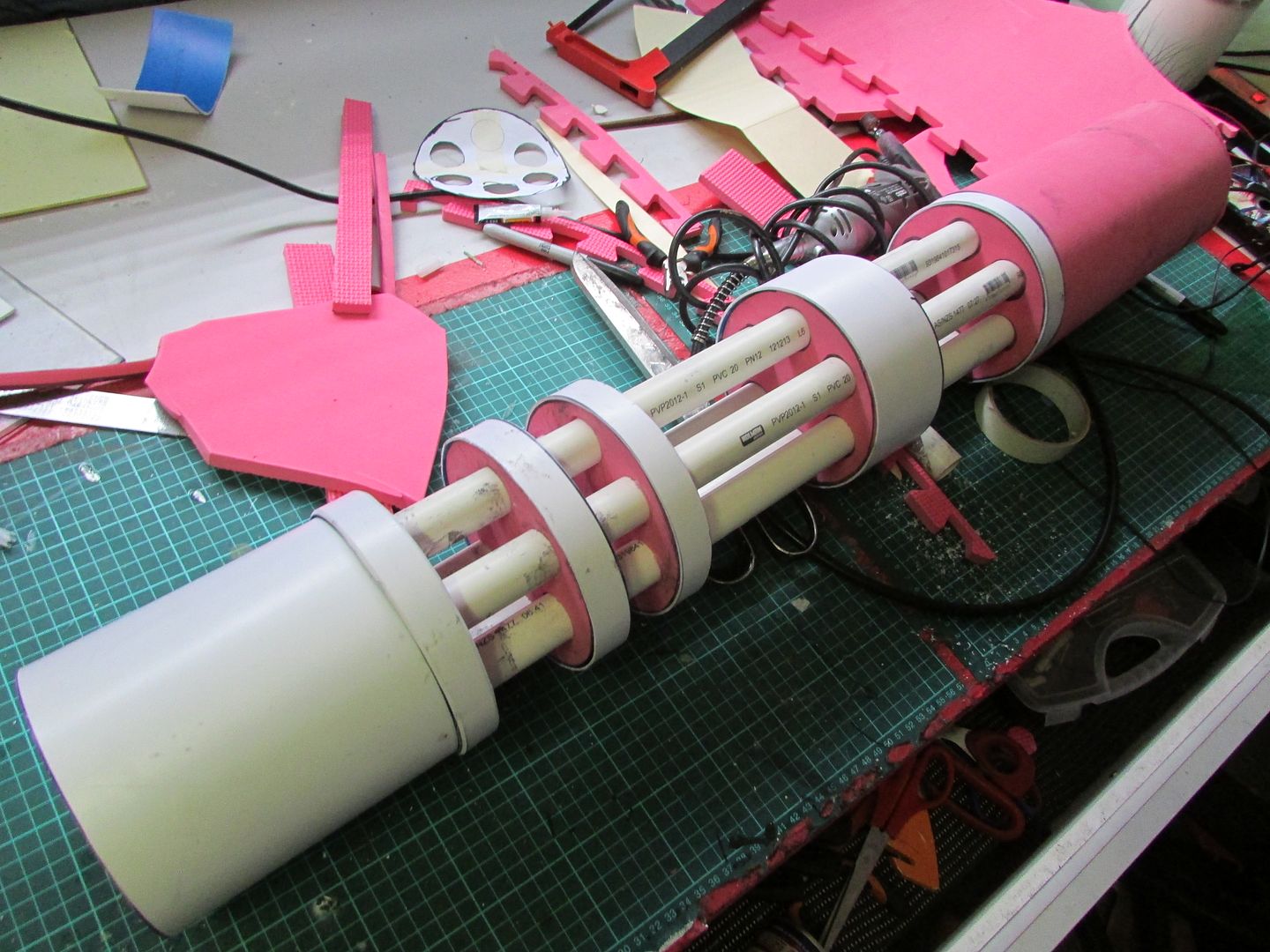

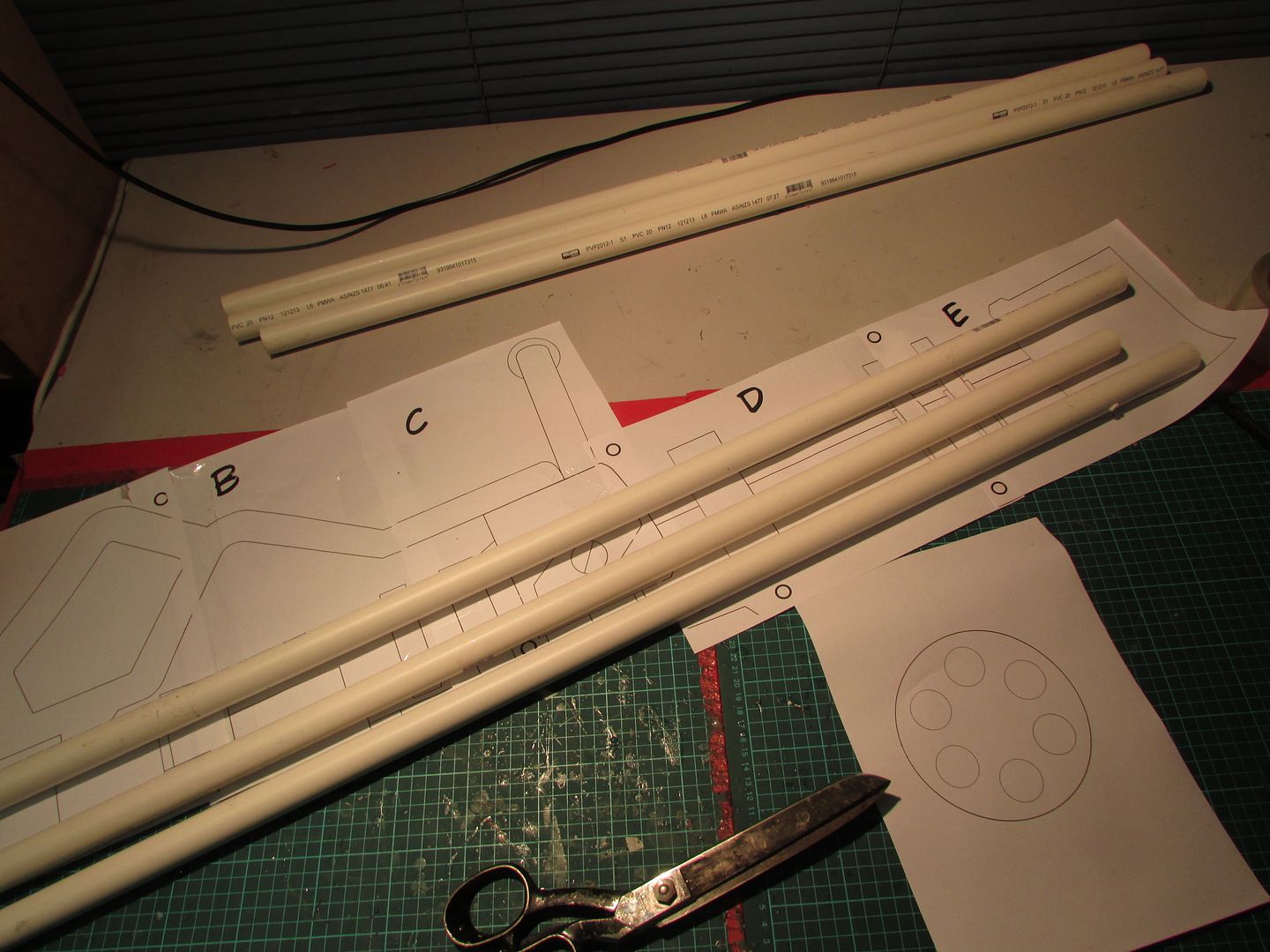

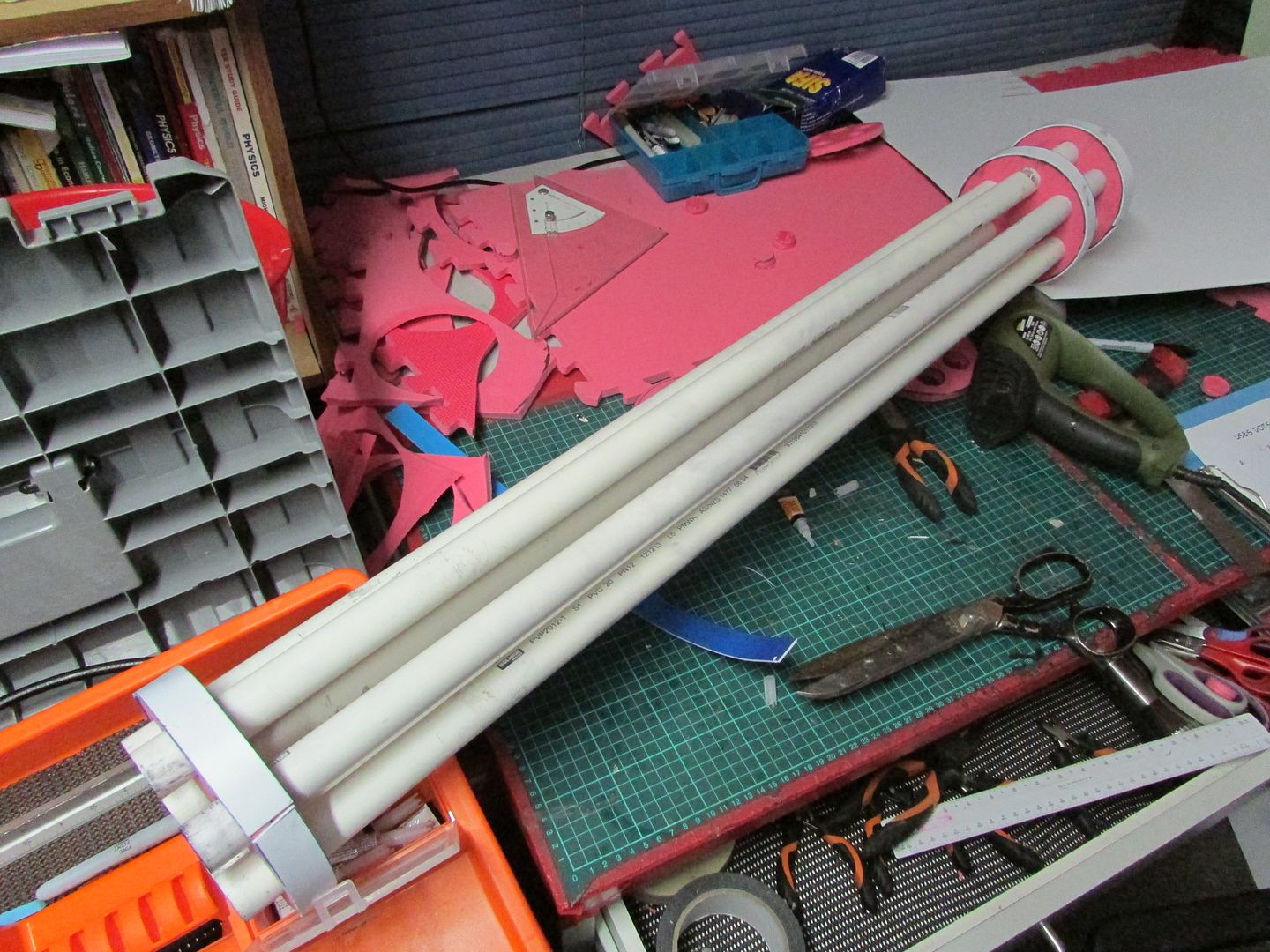

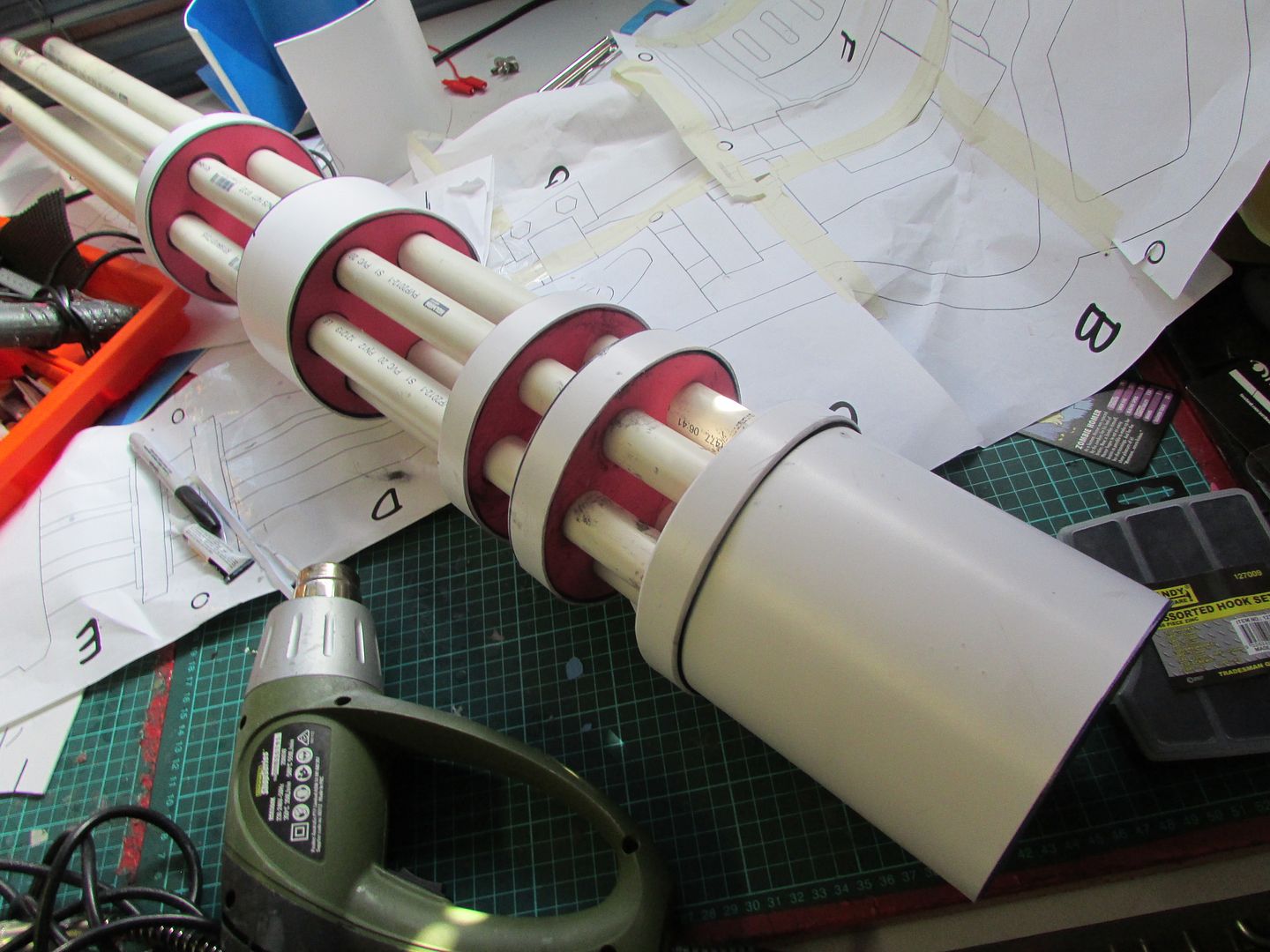

For starters in terms of scaling I’ve chosen to base all dimensions of the gun relative off a 25mm diameter PVC pipe that I’m using for the gun barrels and scaled my vector blueprints of the gun to match suit.

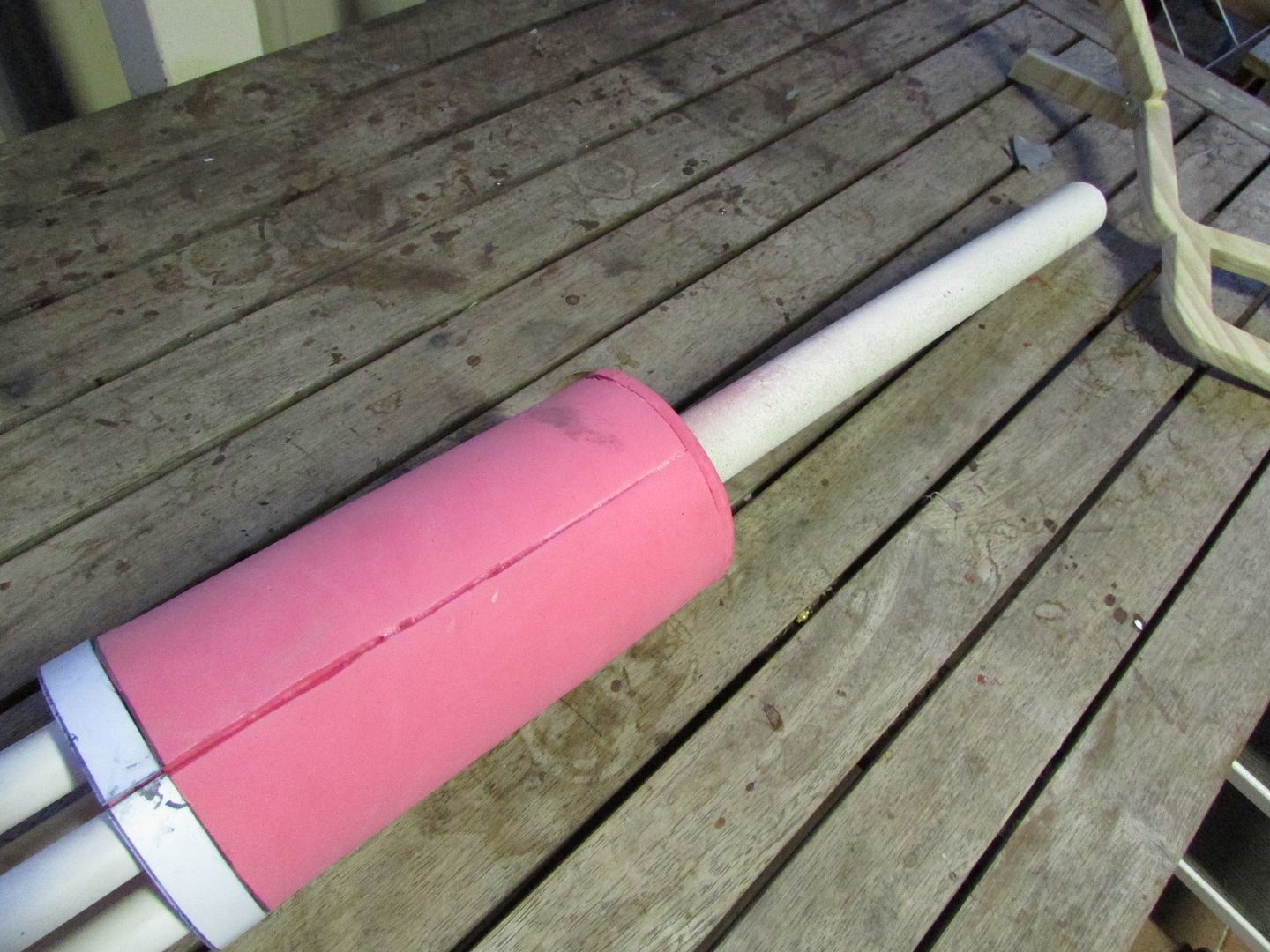

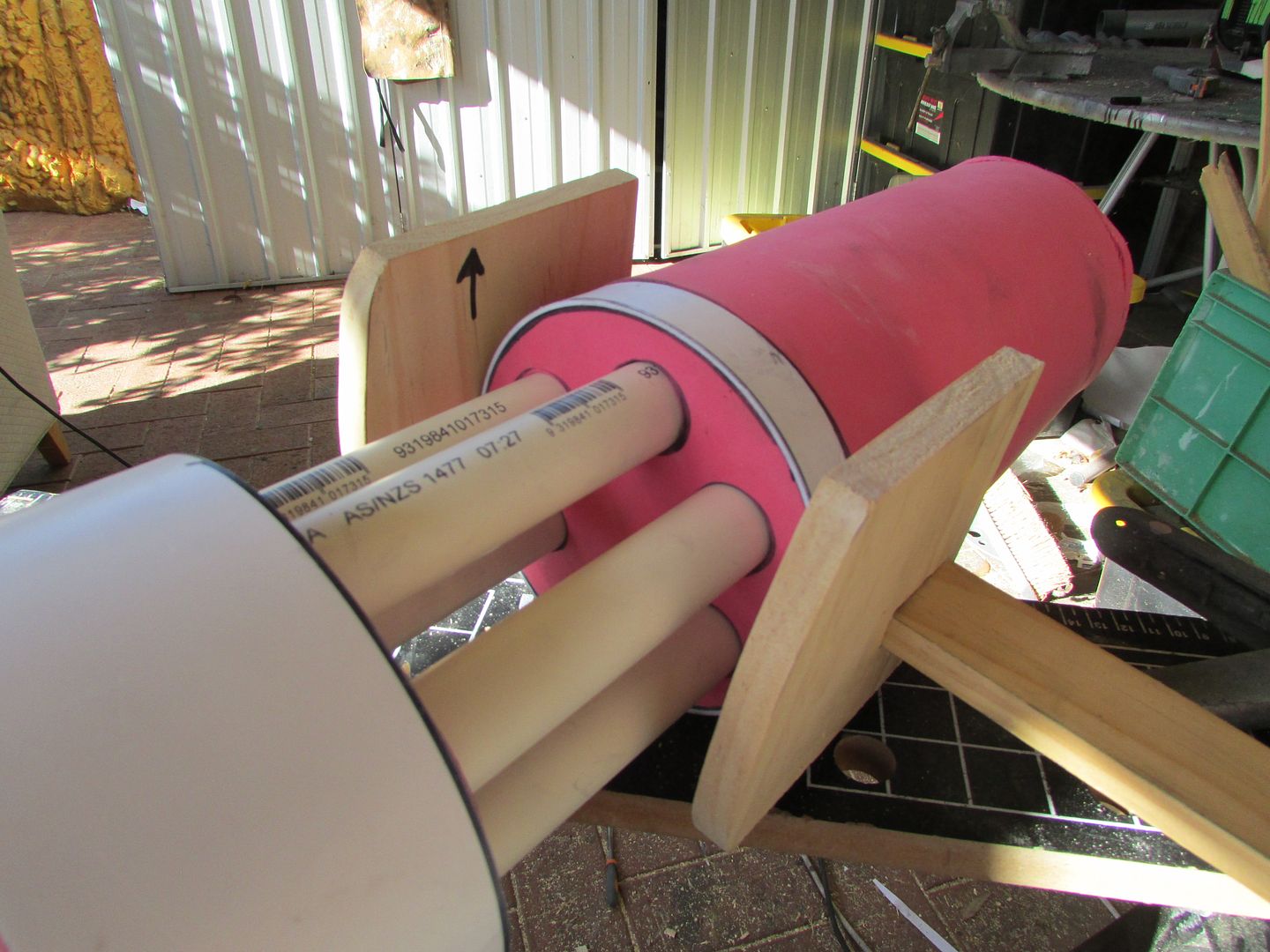

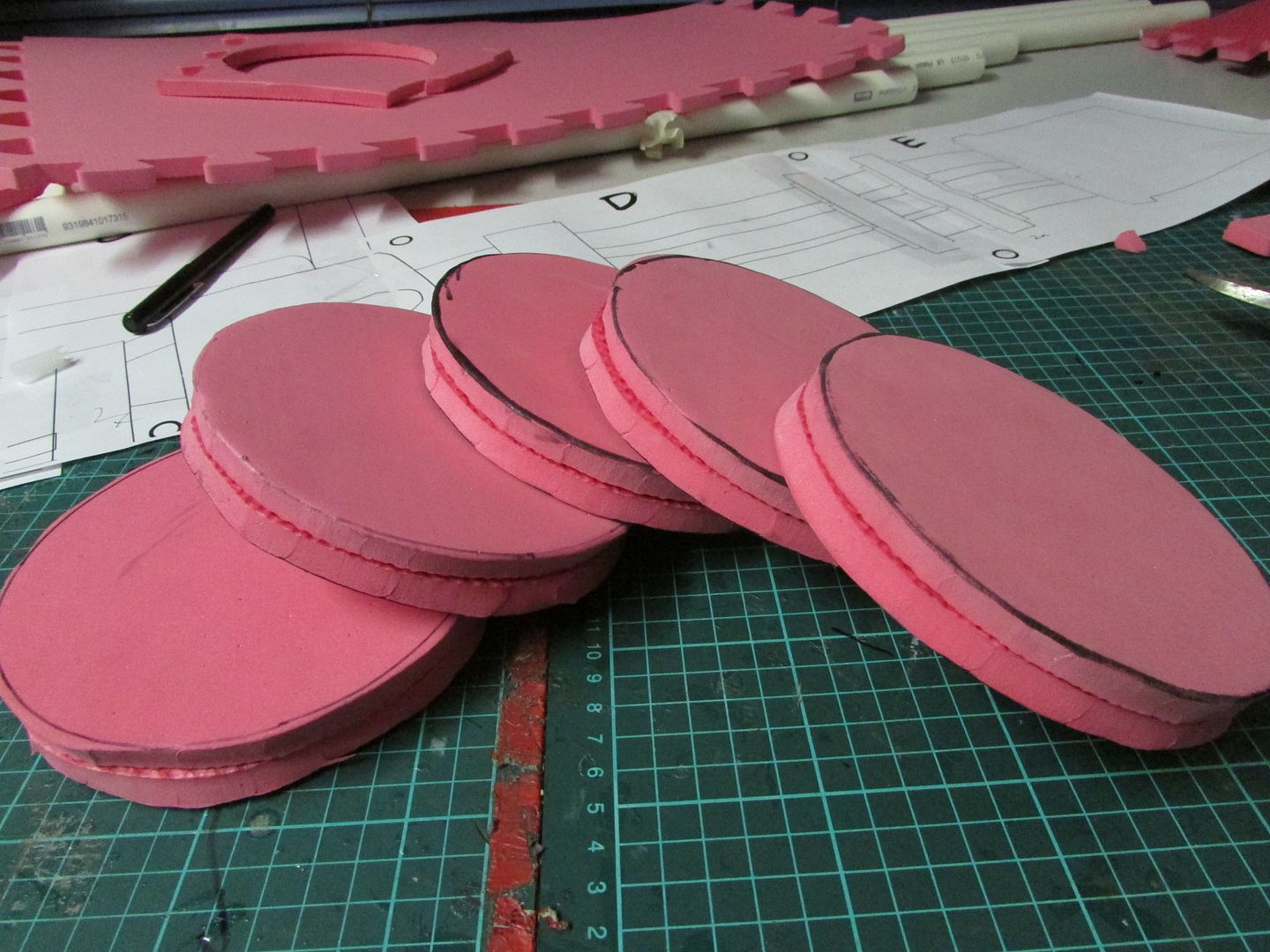

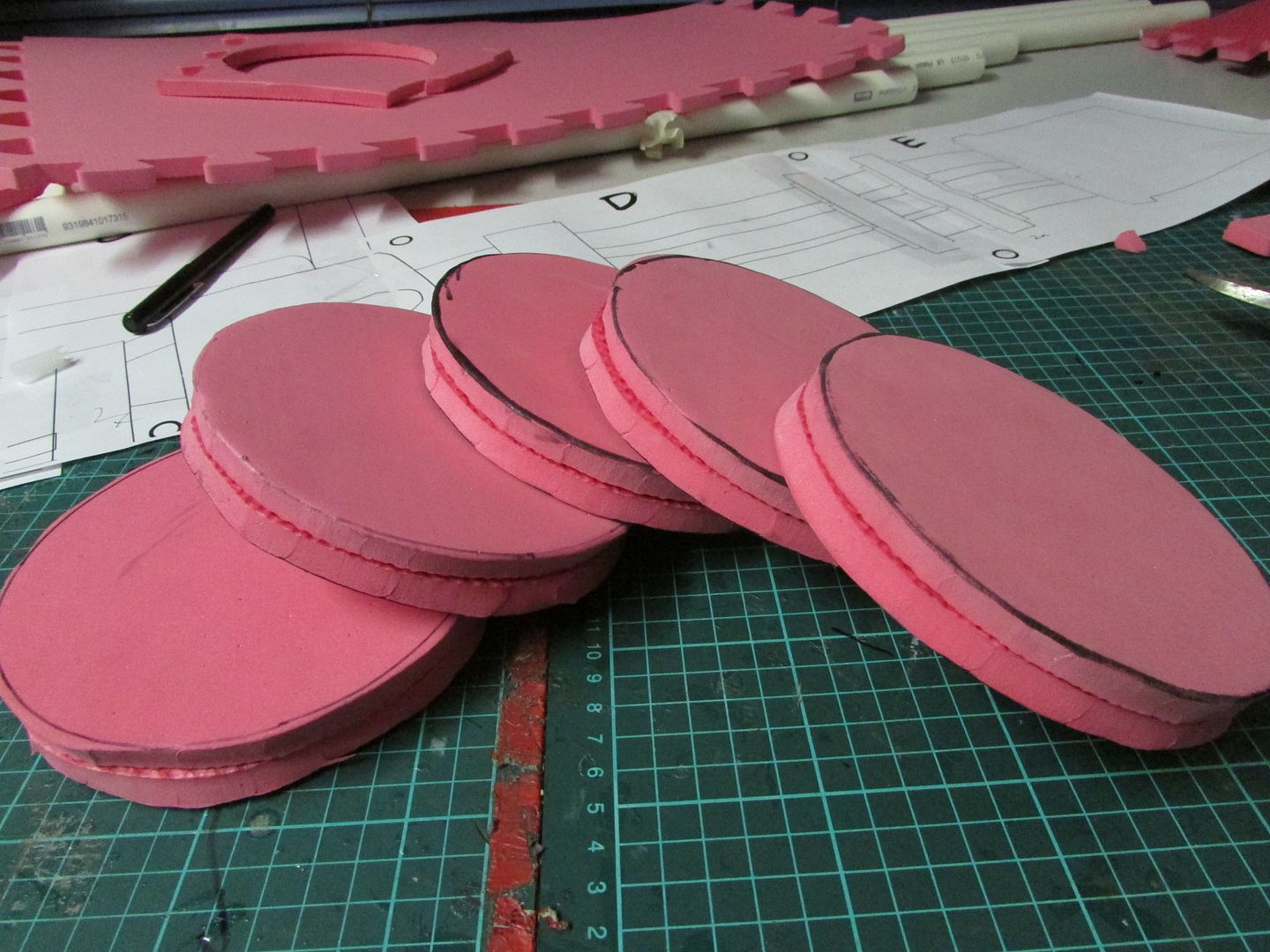

For the barrel clamps, to get the thickness I wanted I decided to superglue some 130mm diamter EVA craft foam circles that I cut out of some foam gym mats back to back. Supergluing in this manner hides the less desirable pattern of the material whilst leaving the nicer smooth side for all to see.

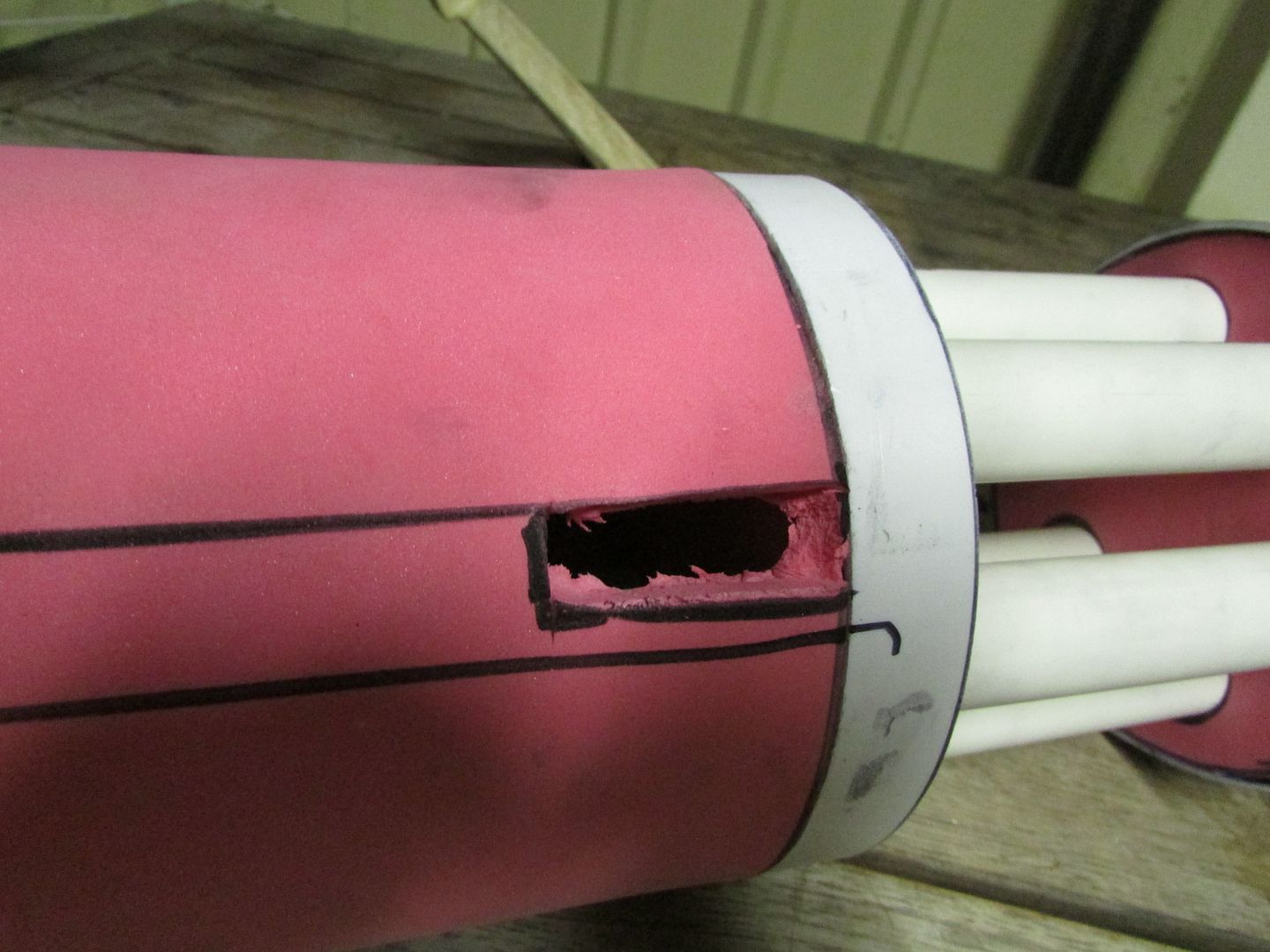

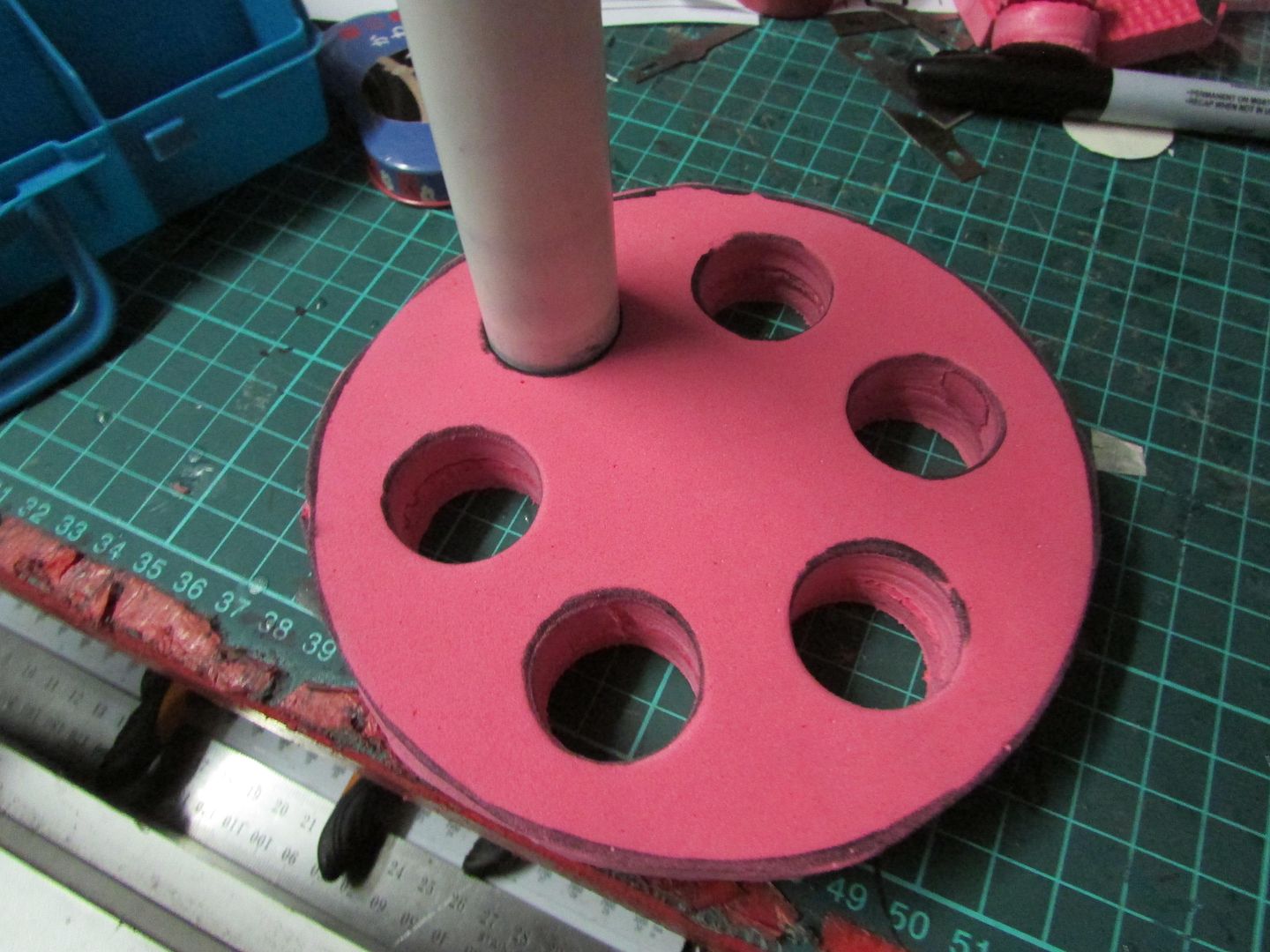

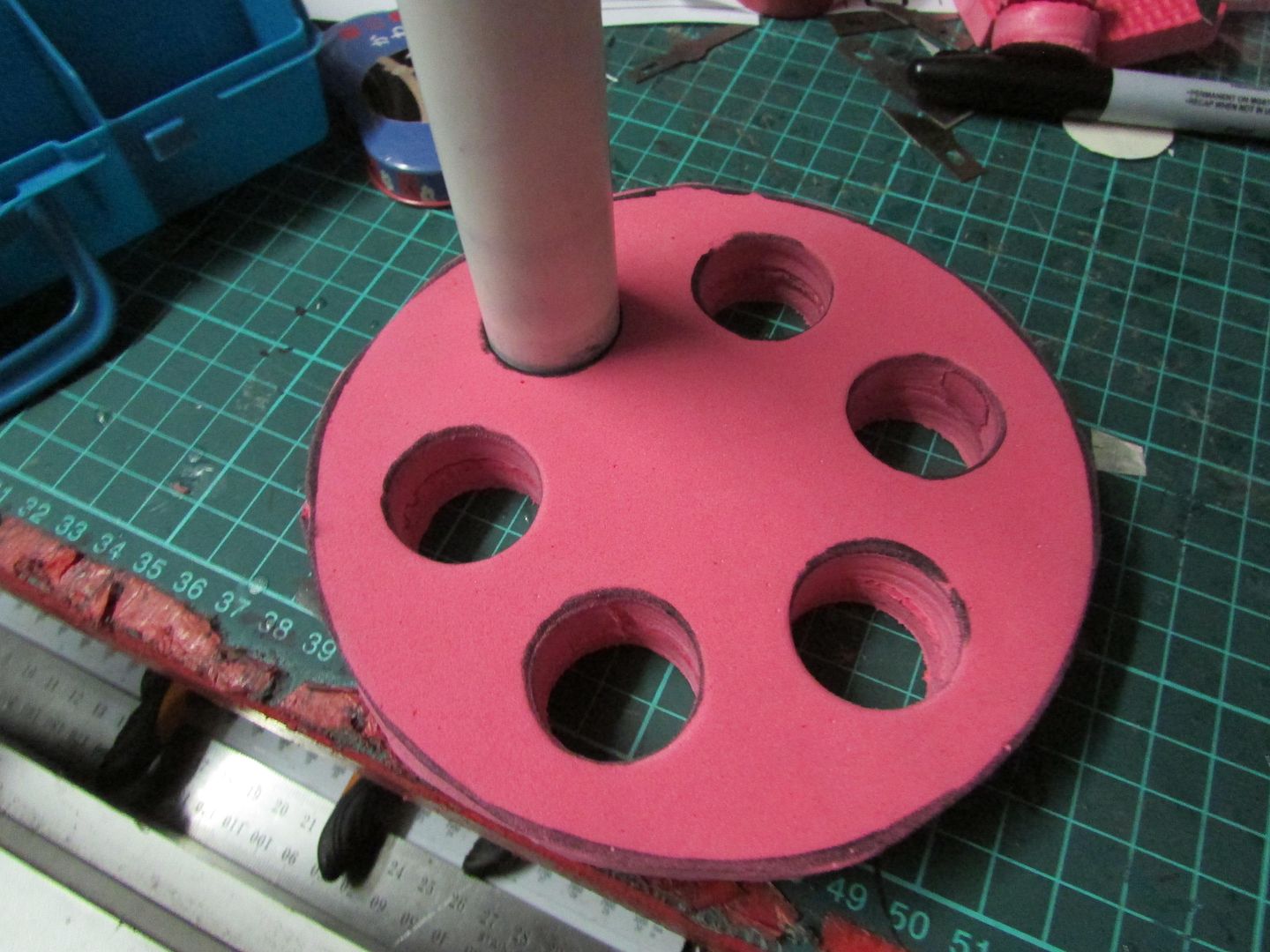

For the holes that the barrels are meant to sit in I plotted out the locations of where each one ought to sit and ended up cutting out the circular holes using the PVC pipe itself like a cookie cutter, using twisting motions making a kind of EVA foam core sample.

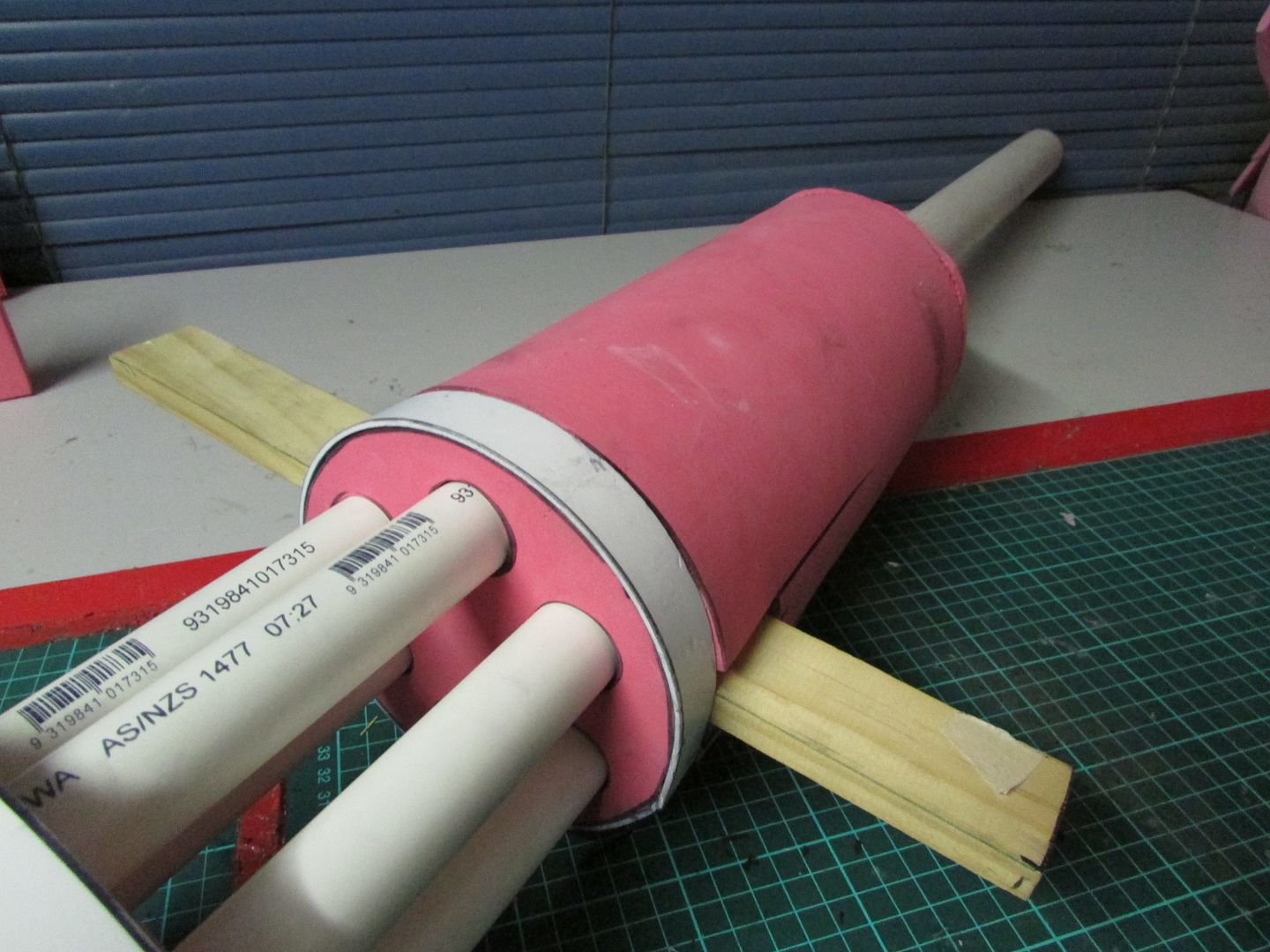

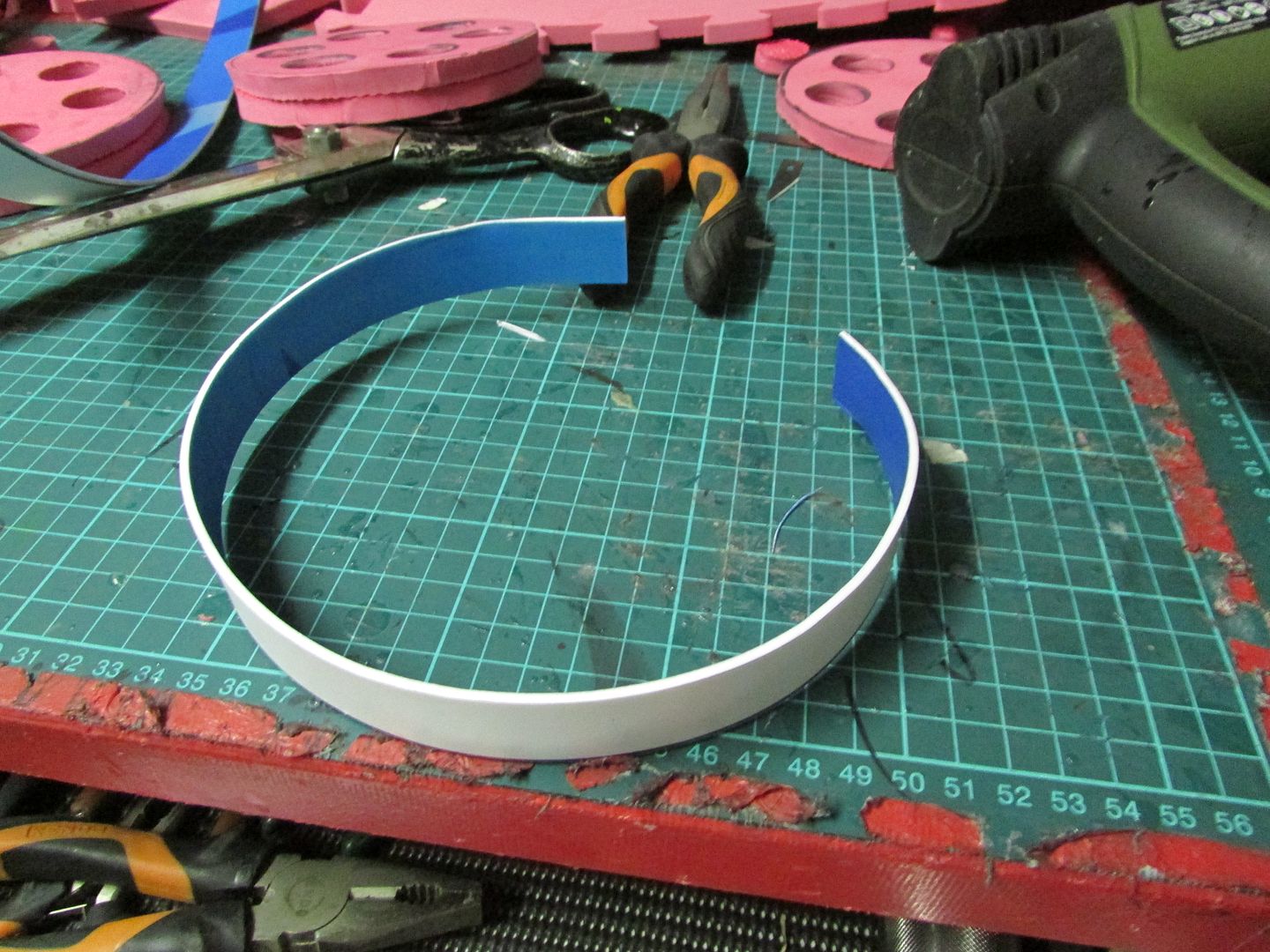

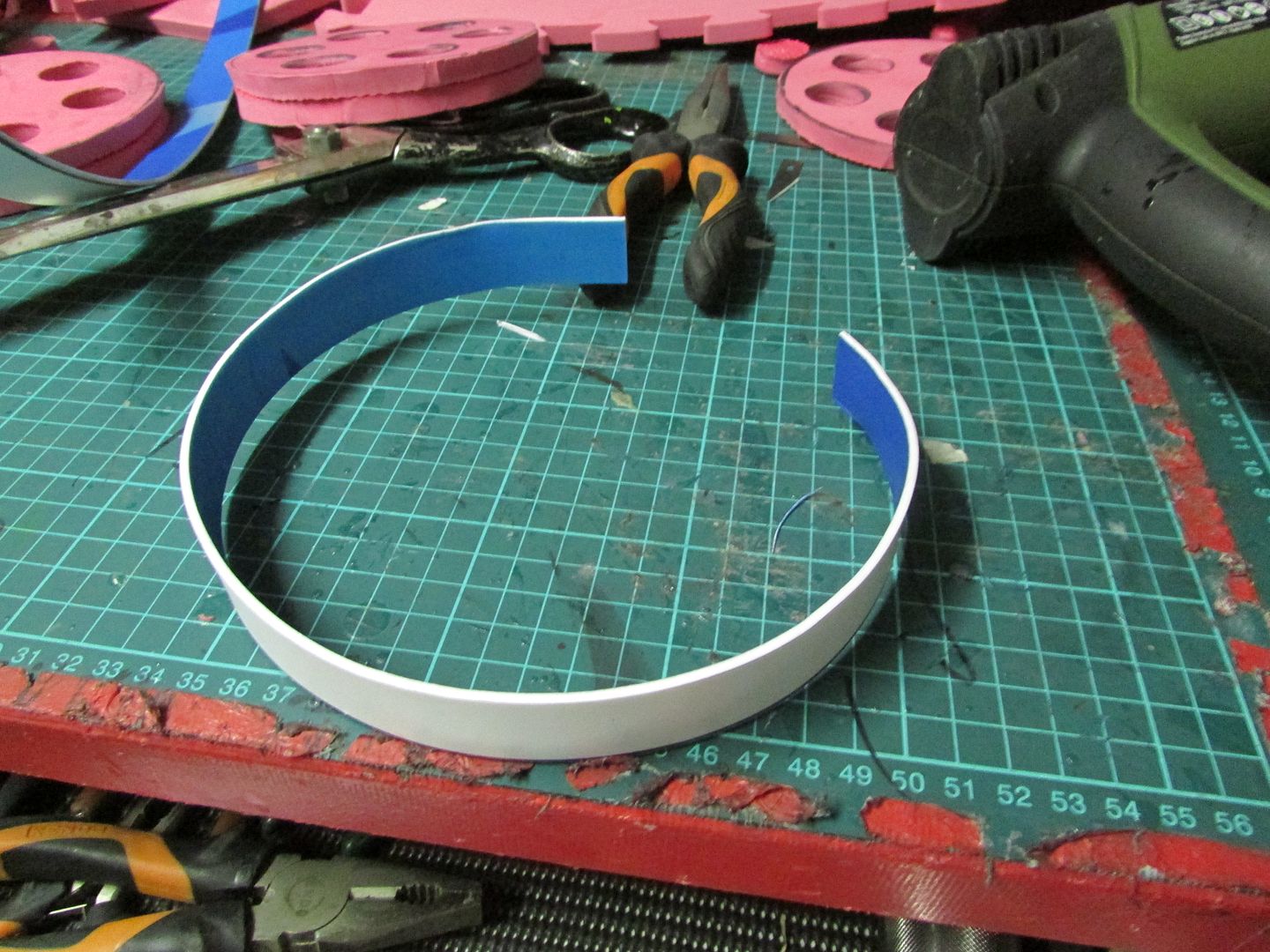

Now to hide the interfacing seams of each of the barrel clamps, originally I was going to use automotive filler and sand it over but thankfully I decide to opt out for some cut to length PVC sheeting that I bent into a circle using a heat gun and superglued onto the foam.

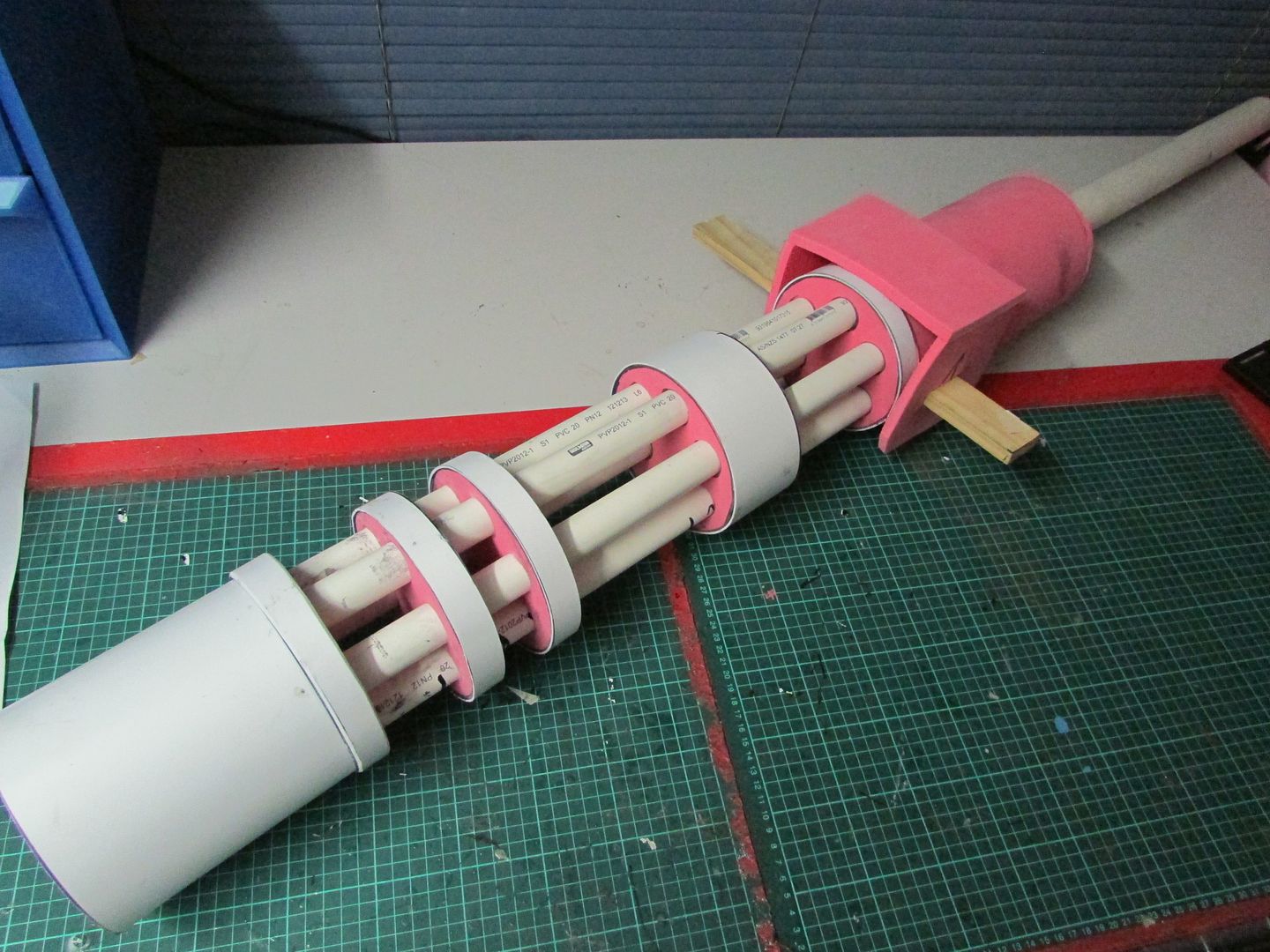

With all the clamps put together it was just simply a matter of knocking them down the PVC pipe till it sat where it needed to match the vector blueprint, to which i superglued into place, I should also not the end muzzle was made using PVC sheeting I had bent with a heat gun.

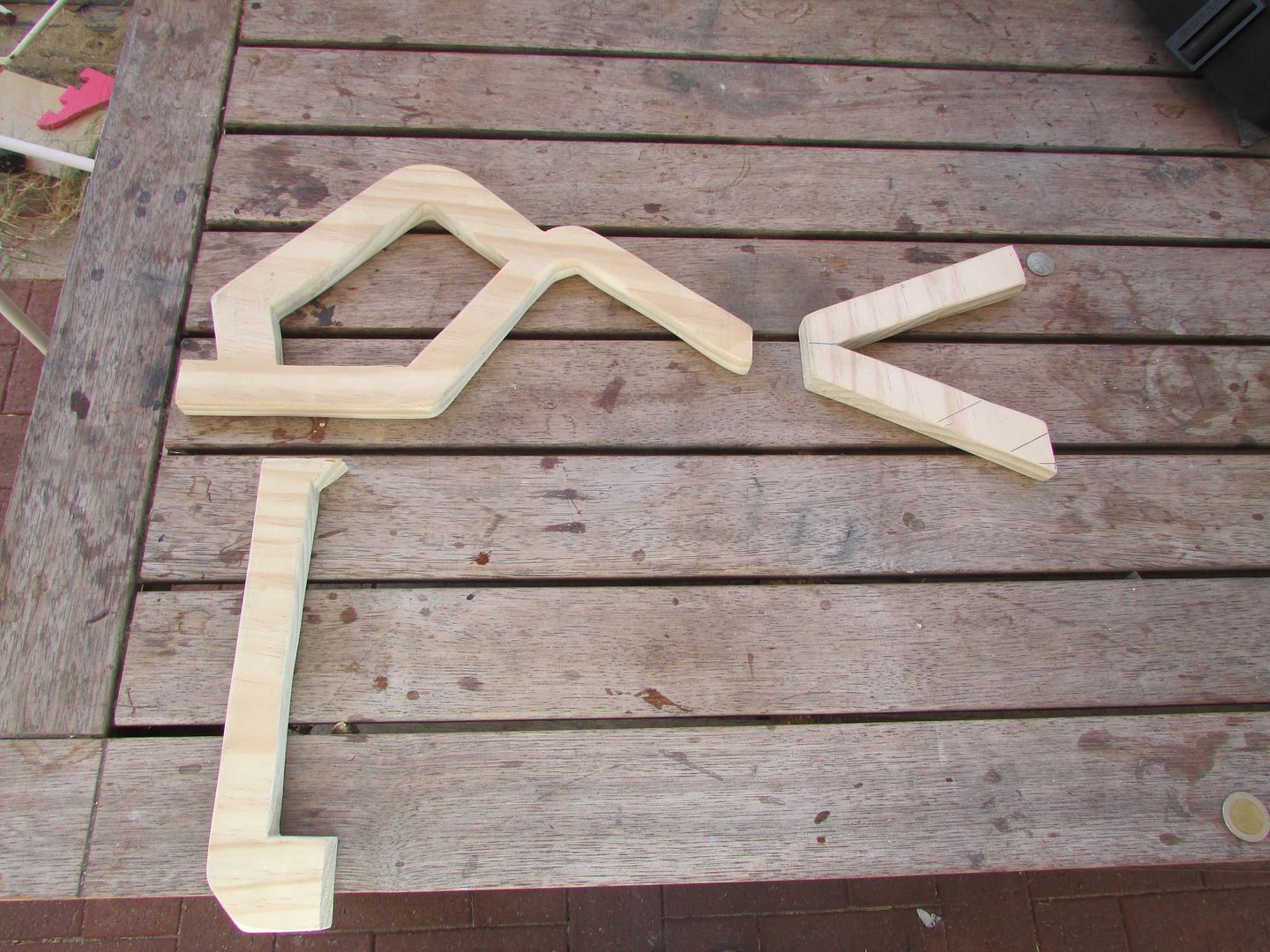

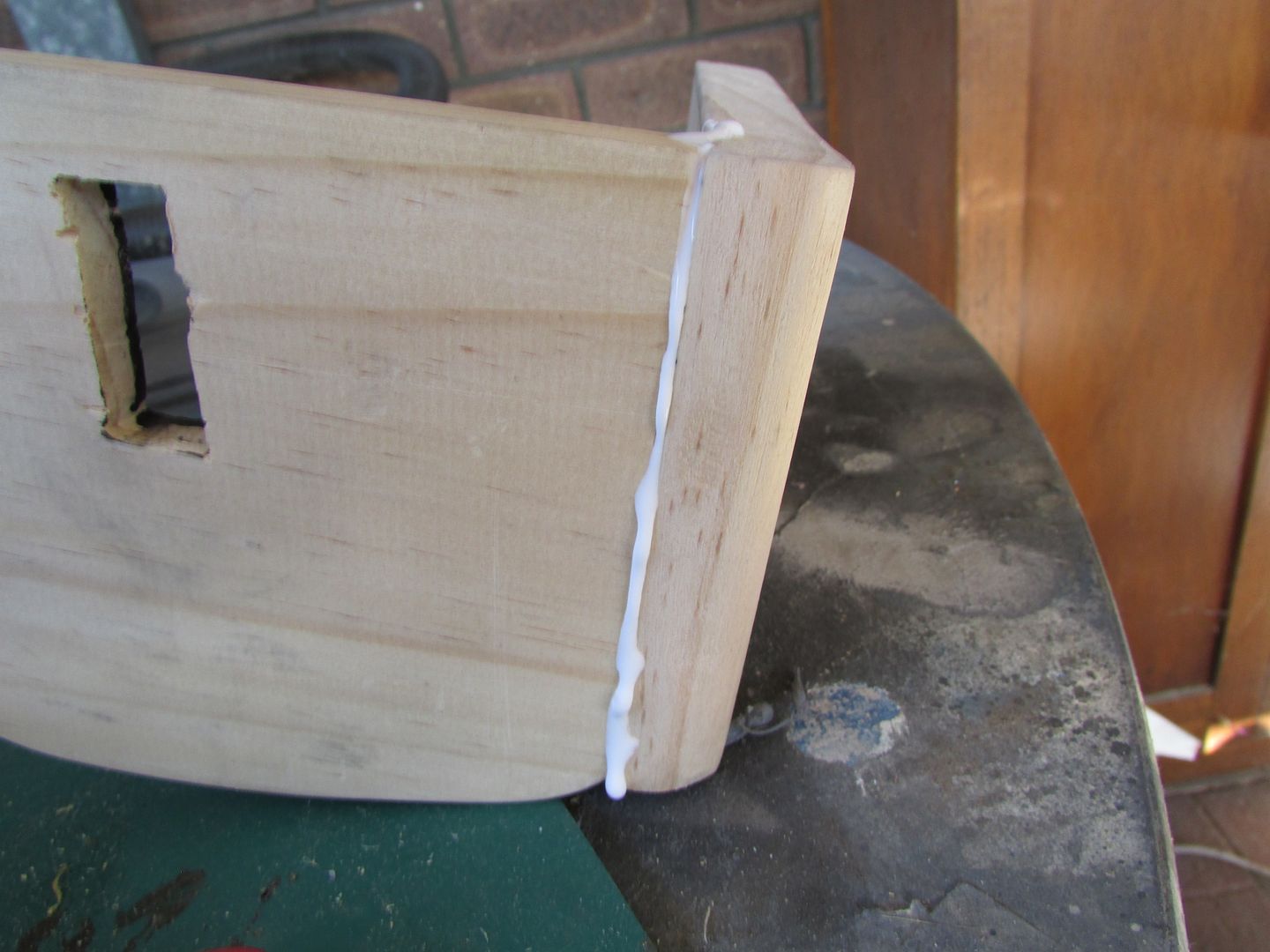

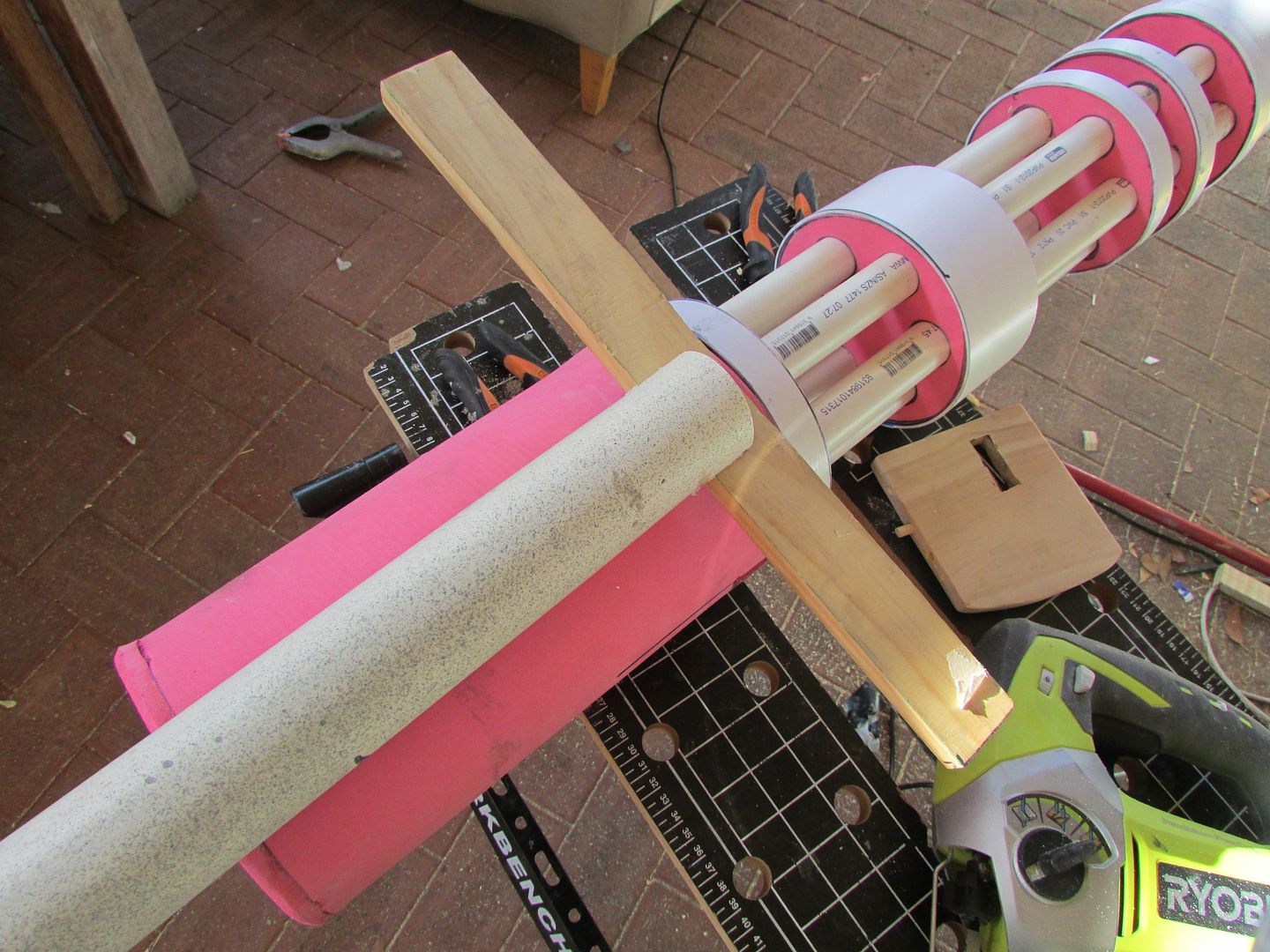

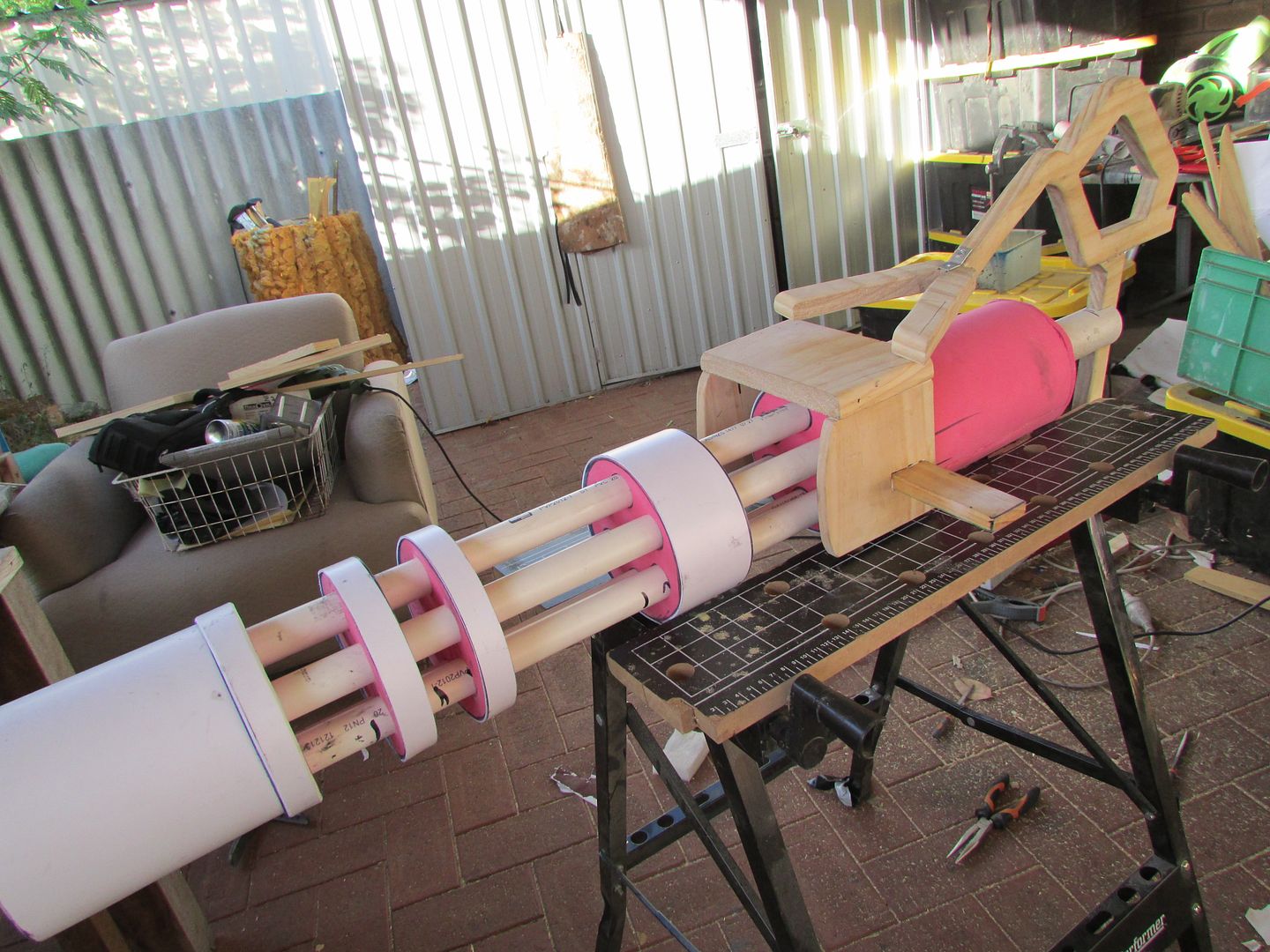

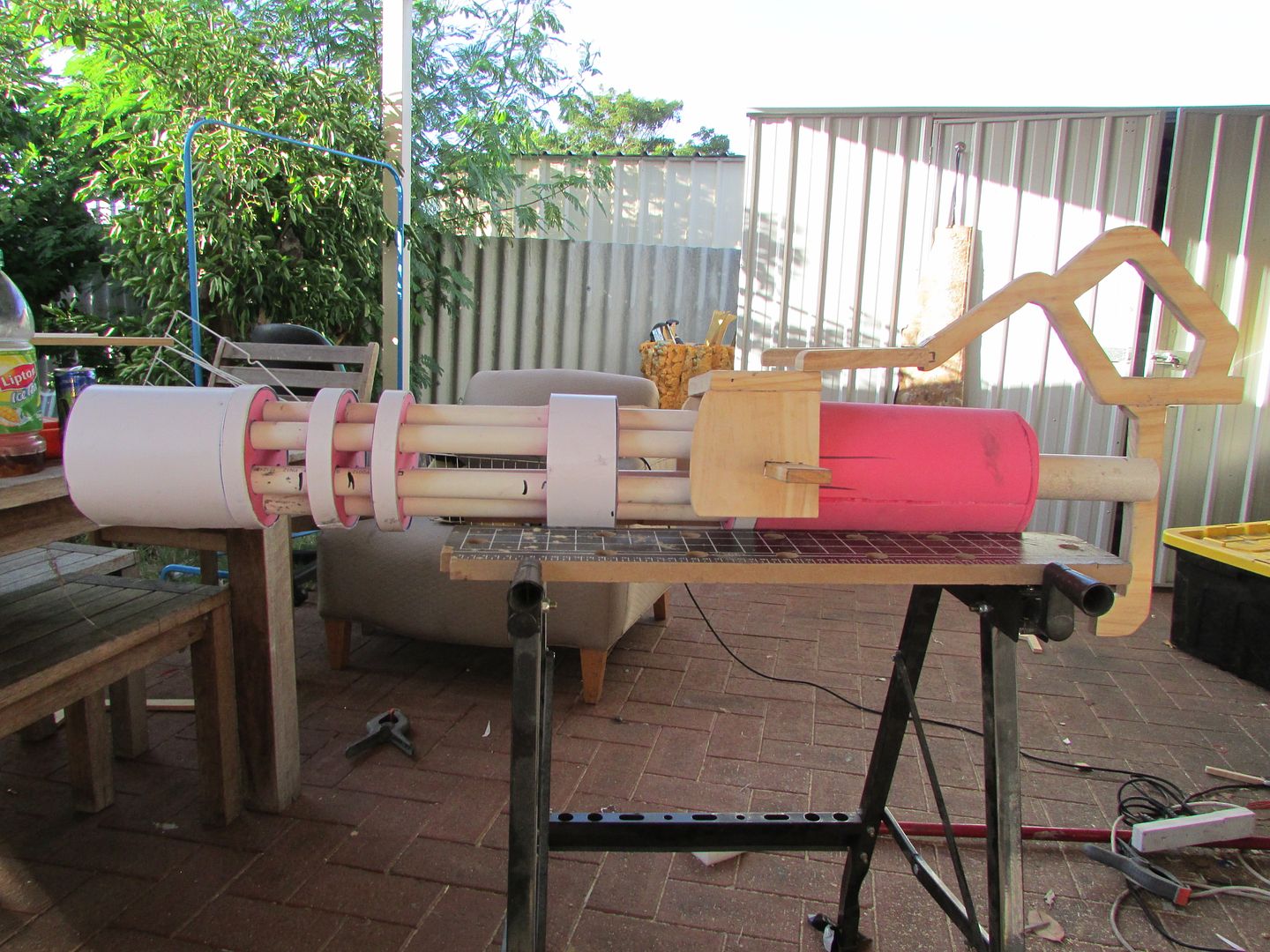

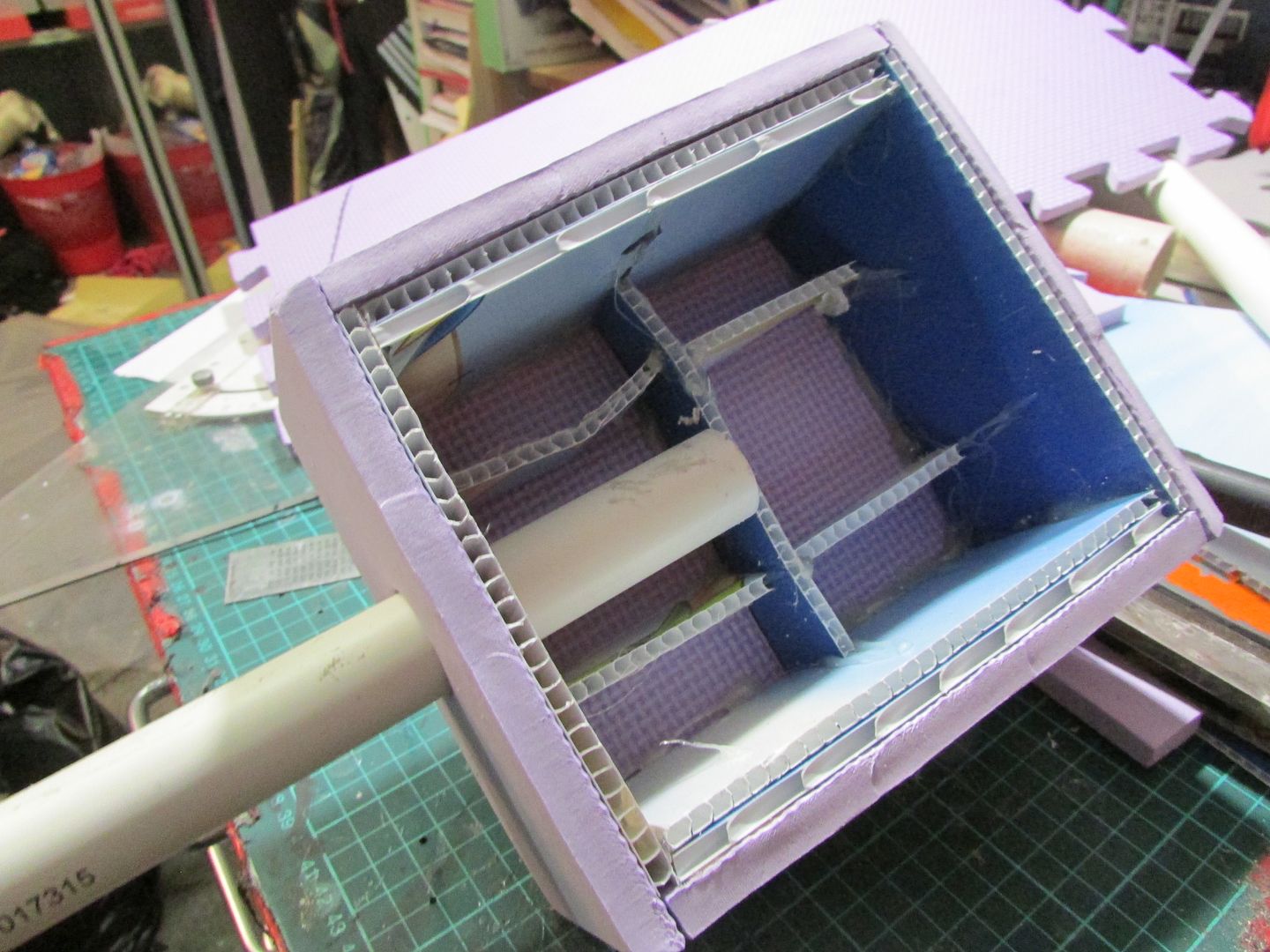

Now to start work on the frame to support everything, so look forward to that.

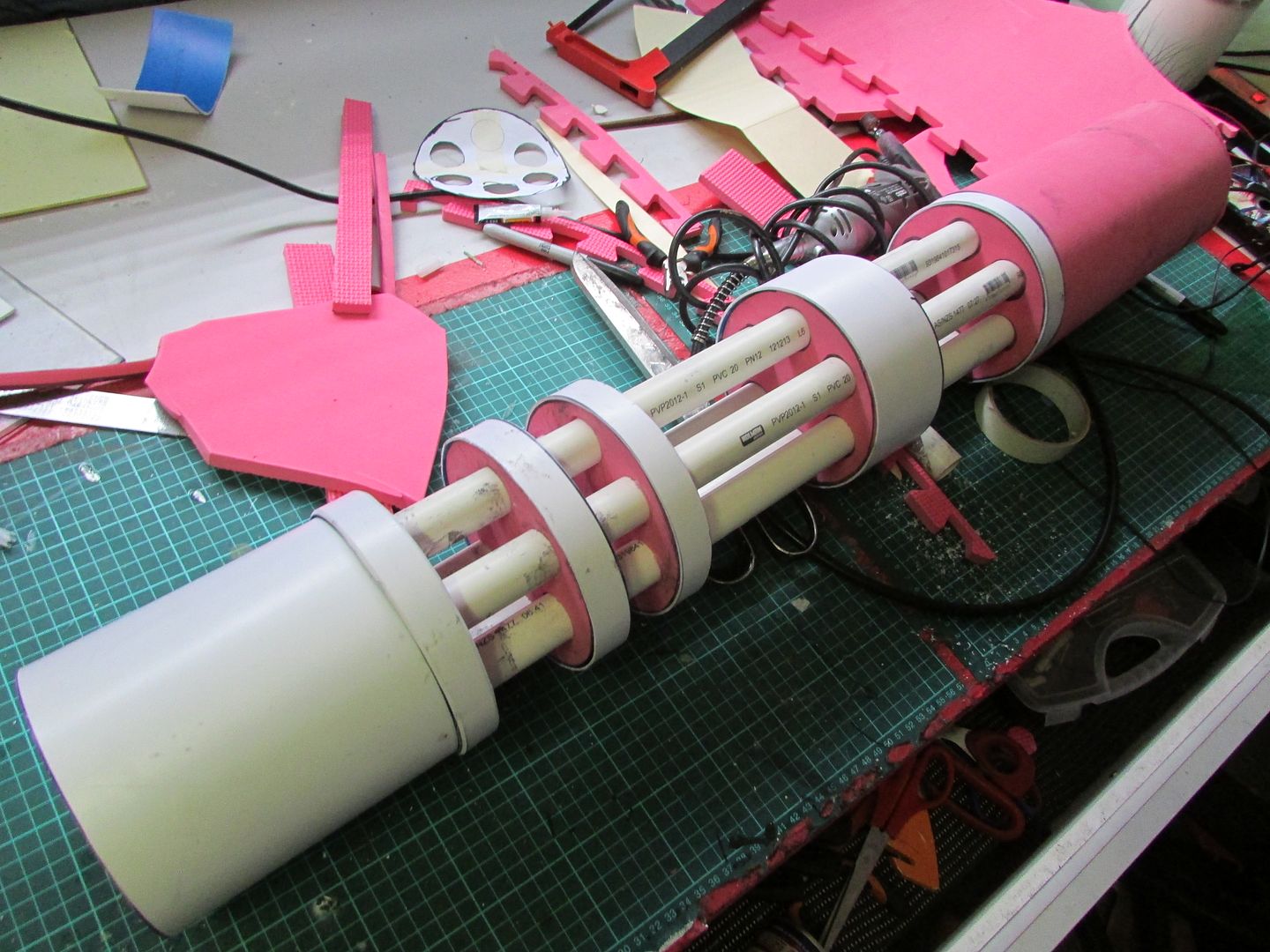

For starters in terms of scaling I’ve chosen to base all dimensions of the gun relative off a 25mm diameter PVC pipe that I’m using for the gun barrels and scaled my vector blueprints of the gun to match suit.

For the barrel clamps, to get the thickness I wanted I decided to superglue some 130mm diamter EVA craft foam circles that I cut out of some foam gym mats back to back. Supergluing in this manner hides the less desirable pattern of the material whilst leaving the nicer smooth side for all to see.

For the holes that the barrels are meant to sit in I plotted out the locations of where each one ought to sit and ended up cutting out the circular holes using the PVC pipe itself like a cookie cutter, using twisting motions making a kind of EVA foam core sample.

Now to hide the interfacing seams of each of the barrel clamps, originally I was going to use automotive filler and sand it over but thankfully I decide to opt out for some cut to length PVC sheeting that I bent into a circle using a heat gun and superglued onto the foam.

With all the clamps put together it was just simply a matter of knocking them down the PVC pipe till it sat where it needed to match the vector blueprint, to which i superglued into place, I should also not the end muzzle was made using PVC sheeting I had bent with a heat gun.

Now to start work on the frame to support everything, so look forward to that.