UPDDATE

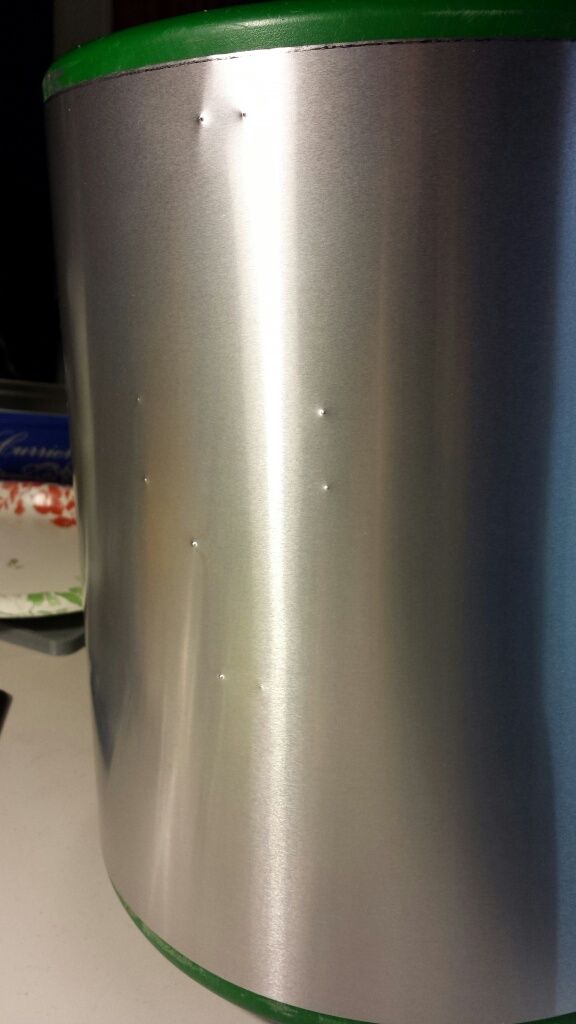

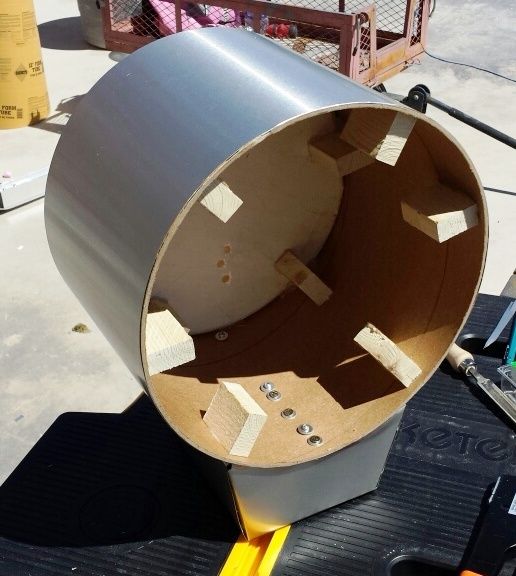

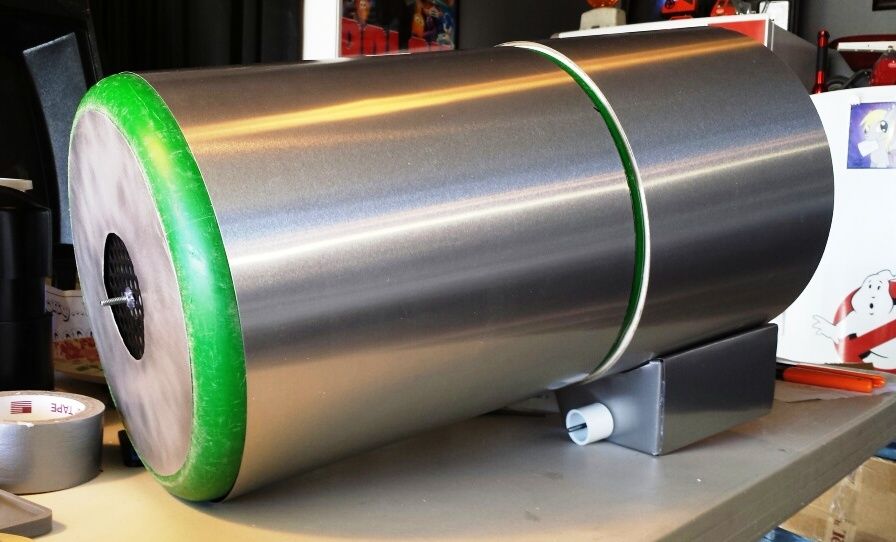

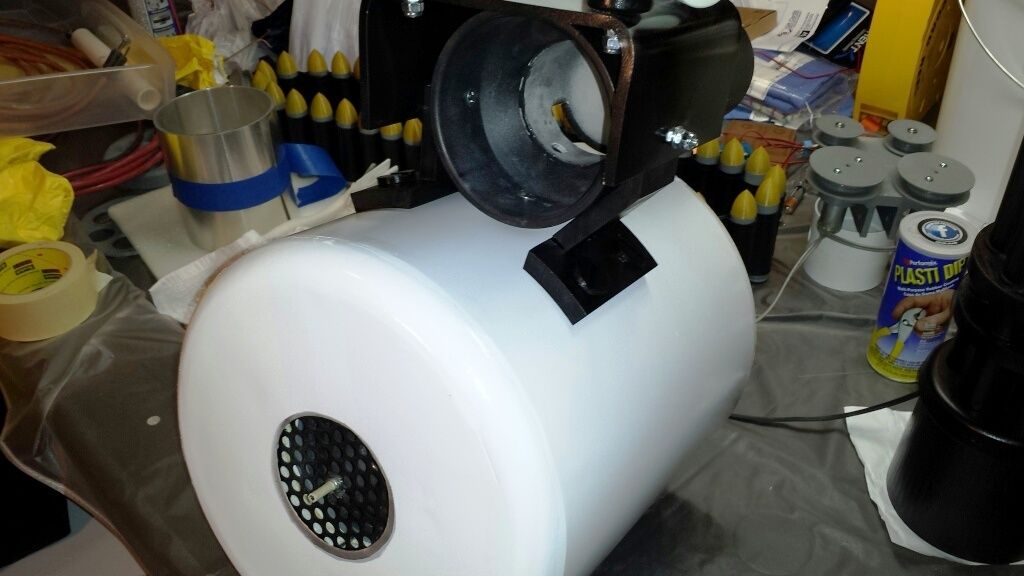

(before you get too excited, I've got to remove the barrel and replace the 3 belts with shorter ones... the ones I installed were about 2" too long)

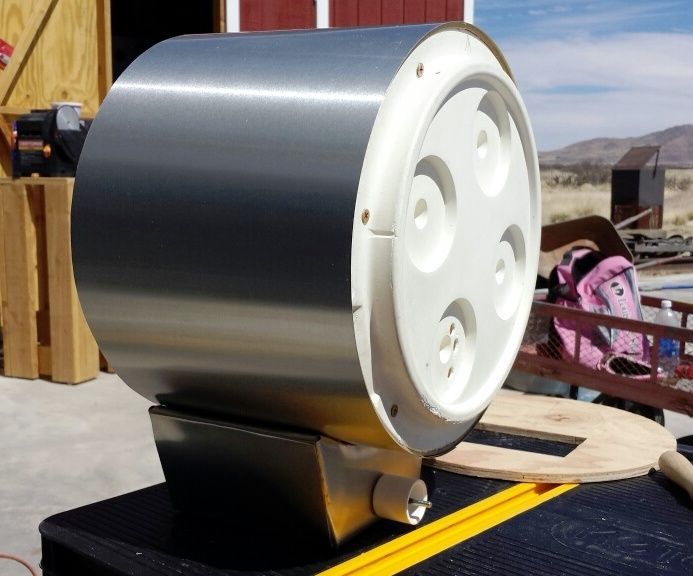

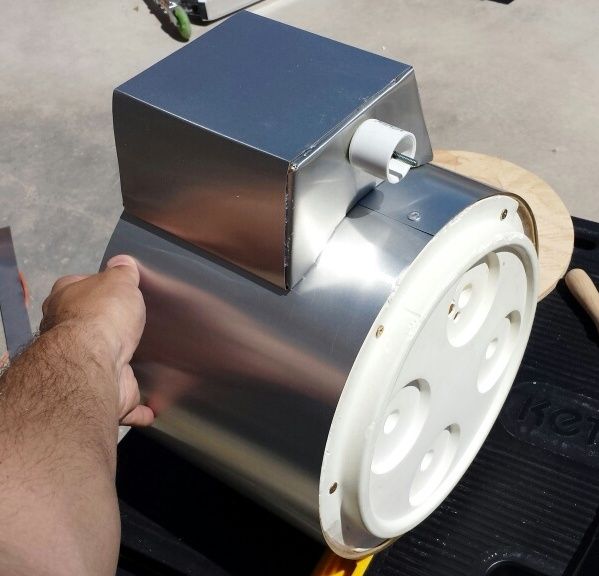

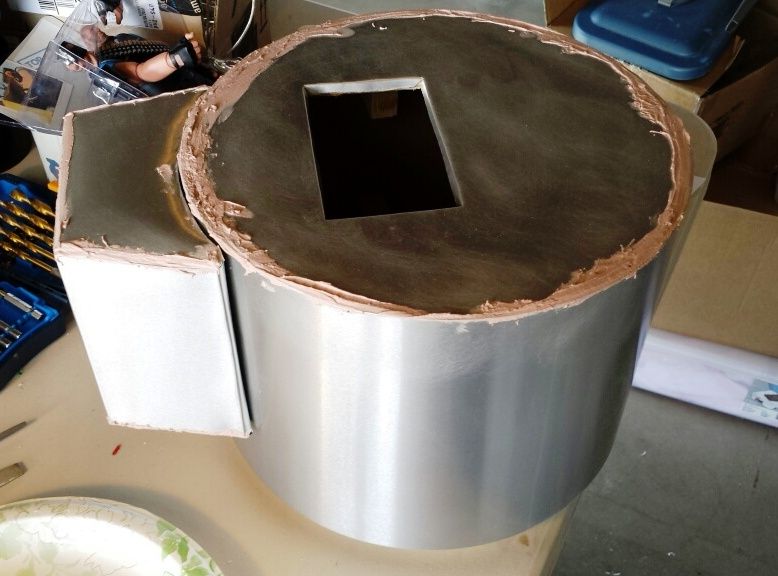

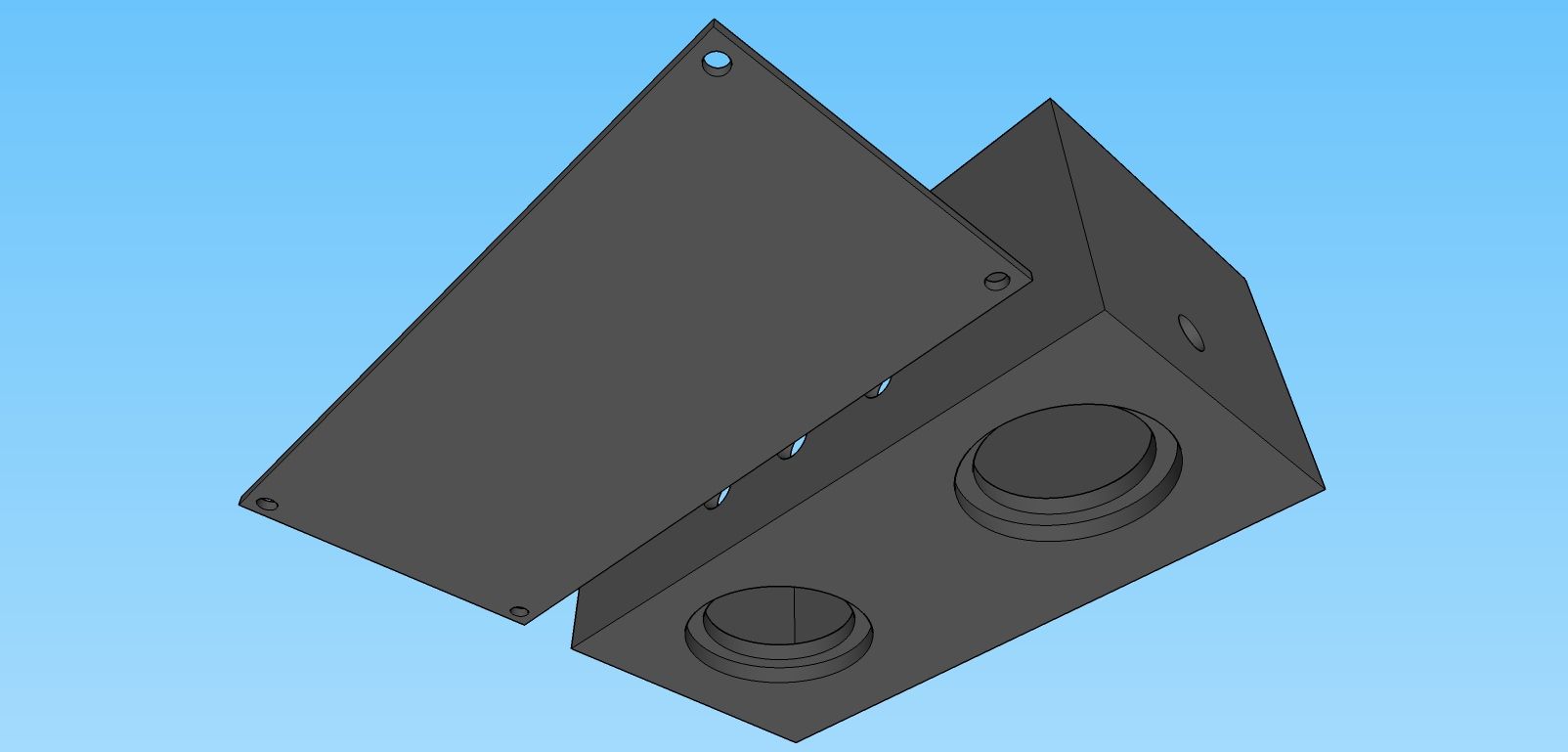

I installed the Rotating Barrel and Belts

Belts and LED lead enter here...

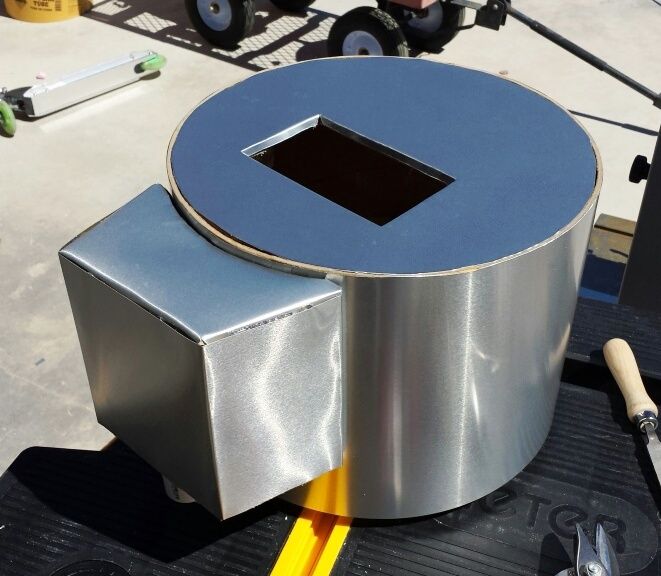

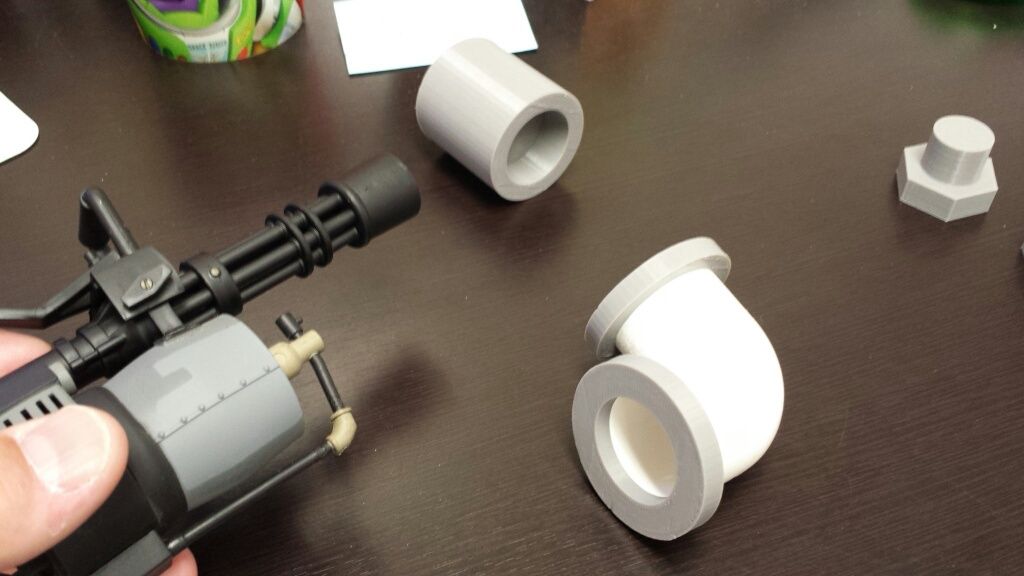

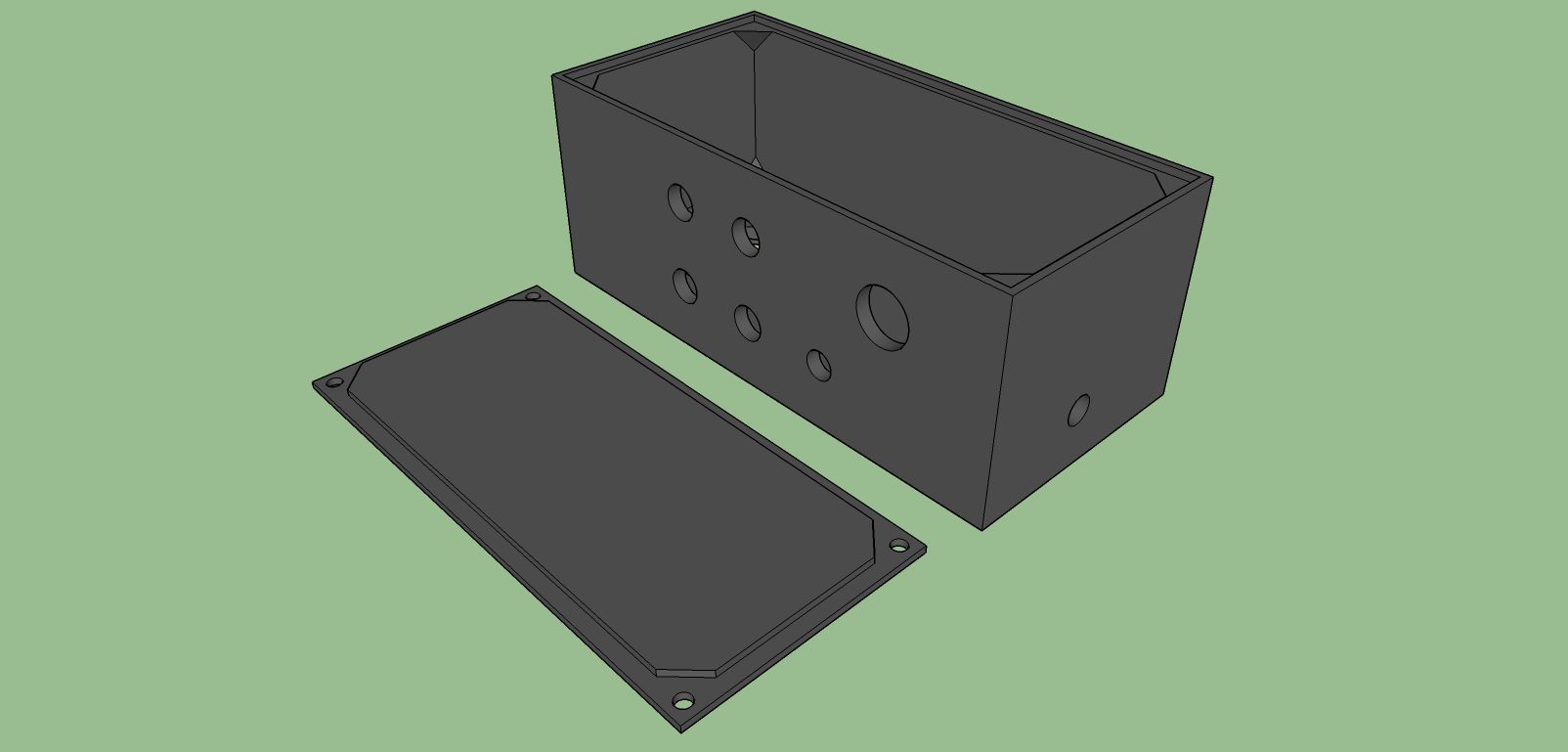

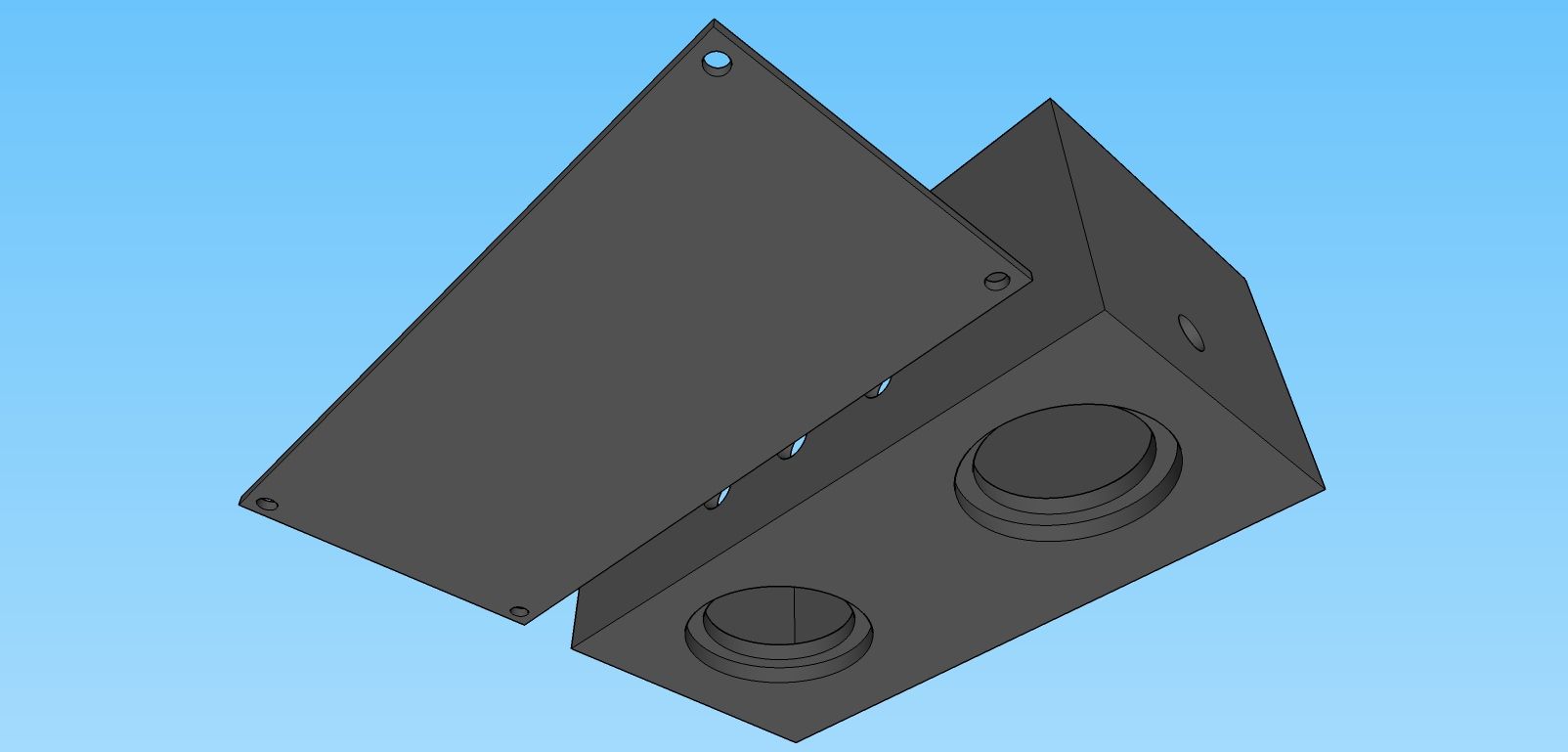

Another part of this project I had to tackle was how to control the lights and motors and sounds.

I've wrestled with how to do this effectively without ruining the appearance of the prop.

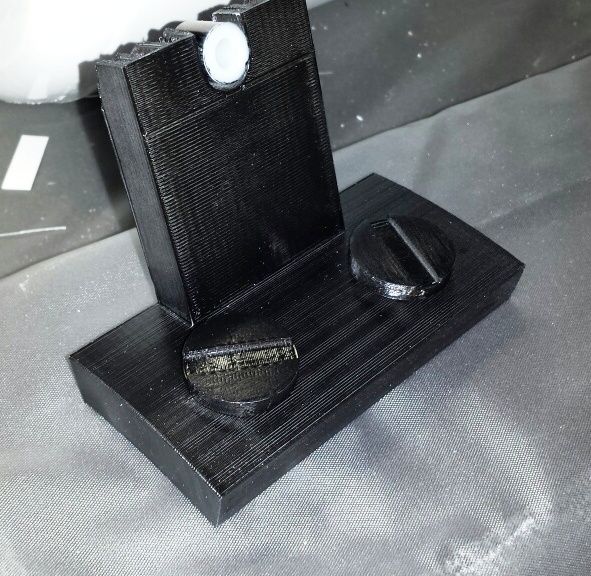

The solution I'm using is to make a custom control box for my right hand (near the rear of the prop, attached to the rear "handle") to work everything.

This box will be against my right hip between the rear frame and my body... fairly hidden, but accessible.

It shouldn't show up in photos or detract from the appearance of the finished prop.

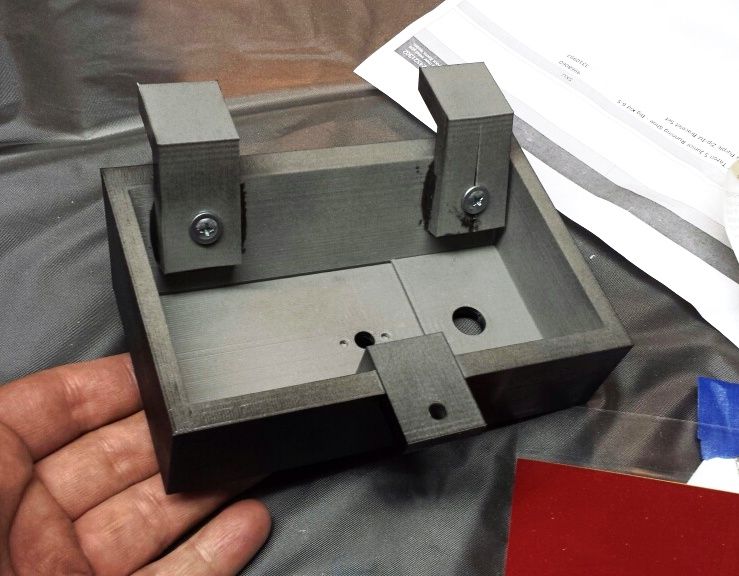

I will attach it using JB Qwik around both registered fit holes and ONE bolt + fender washer (or small bar) to hold it flush against the frame, so it won't break free from stresses of use.

Anyway, here it is...

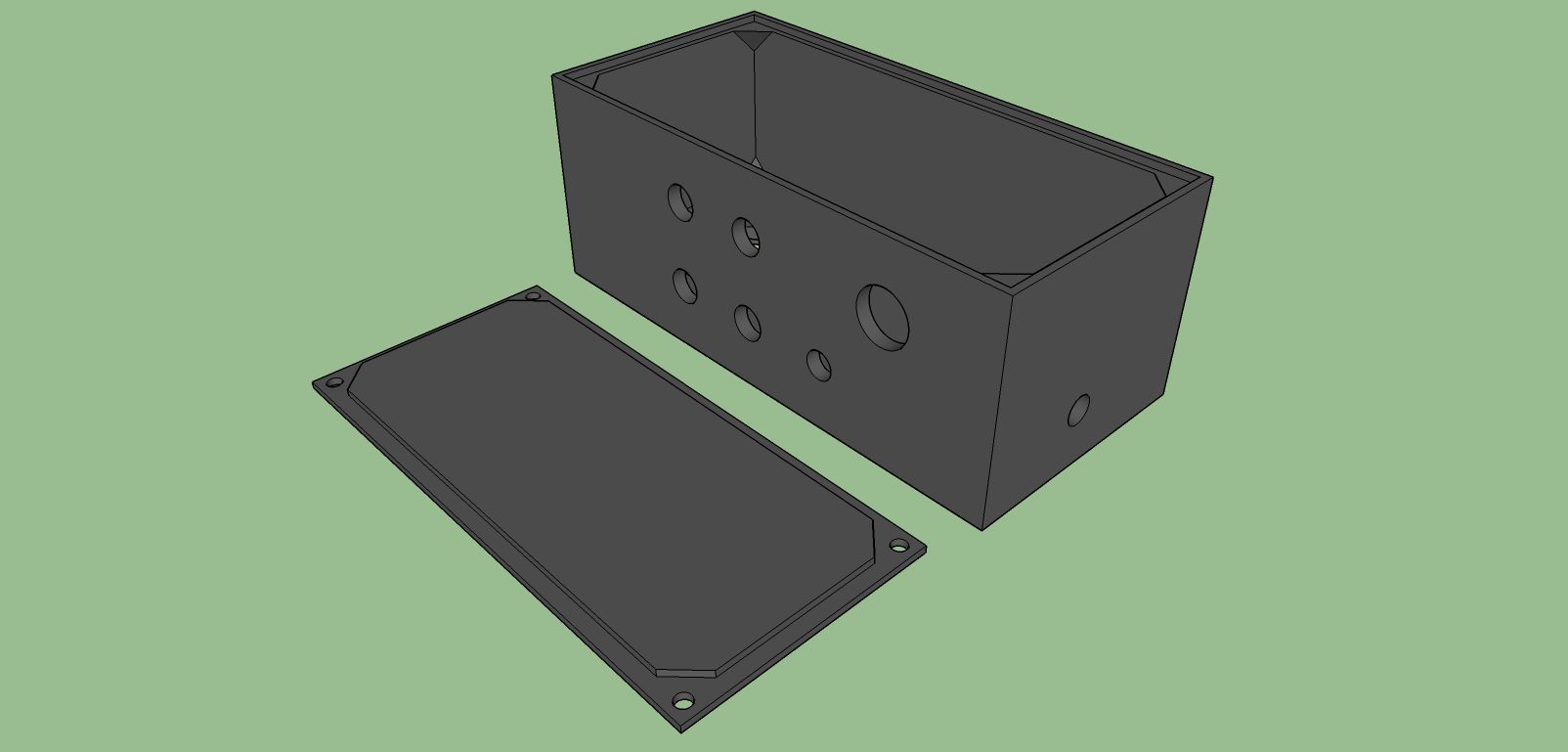

The switches work as follows:

- large toggle (black) - engage/disengage motors + wind up/wind down sounds

- red switch on front end - engage/disengage LEDs + firing/spinning sounds

- small toggle (silver) - select firing sound (standard or crits)

- 4 smaller pushbuttons (red and black) - trigger other sound effects

Next steps:

- replace belts with shorter ones

- final test of motors and LEDs

- button up front and back cans