CustomCreations

Sr Member

Hi,

I've been lurking in the forums to watch peoples amazing work in their builds for the Dredd Movie, and thought I'd post up my current progress on a Lawgiver Mk2 build I am doing.

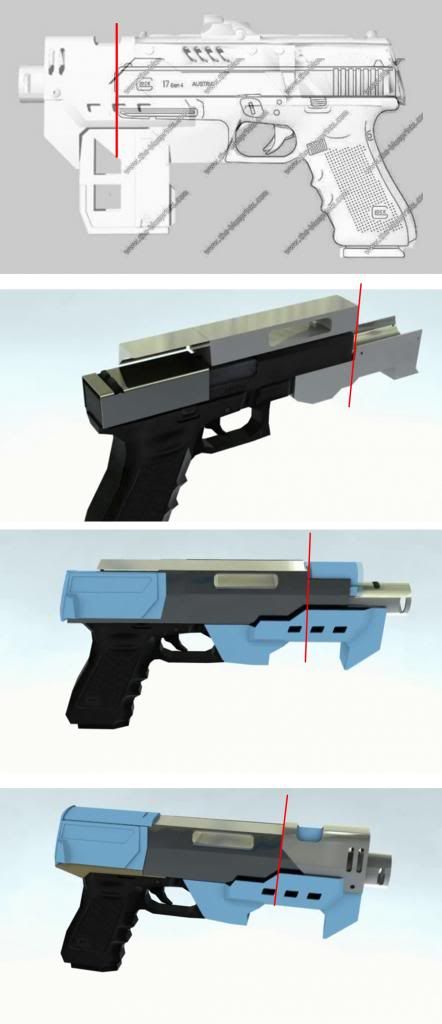

The basis of this build comes from the original CAD files that I was able to obtain....;-)

The files I had were a low res conversion so although looked ok on screen, were very triangulated.

The downside of this is that this meant they were unable to be ammended, sliced or generally reworked.

So I set to work remodelling over the original files to get real CAD data, this also smoothed up all the faces and gave me modelling that could be adjusted and tweaked.

Although I have a CNC machine of my own, its a 2.5d and working with the files gradually I realised that the best way to handle the build was to 'Old School' it.

I printed out the various shapes and forms and using styrene, built up what I could over a cheapo Glock Airsoft.

This gave me a 'case' which slid over the bulk of the gun and a platform to stick everything to when the time came.

(The original gun is made up from many layers of aluminium panels.....)

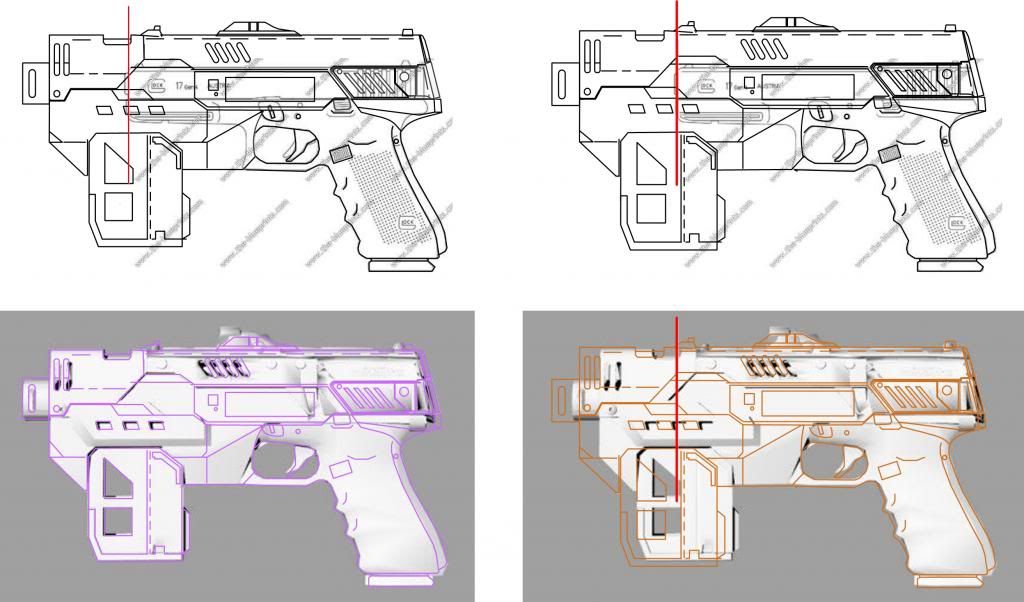

I then started to CNC the detail parts.

One thing of interest is that it looks like the original Location of the LCD screen and serial No. was over the rear slide.

The LCD screen seen here was a slightly earlier version based on what reference I could pull from the Net as this part of the LG was not in the orginal file.

Currently the gun is still in component form. I now have STL files of the original rear slide section ( which when the gun fires slid back) . I have yet to start this section based on this new file, although the original work I did in this area is correct, thankfully !

Of interest to anyone tackling their own build, It would seem the gas Blowback ( blue) and the cheaper one-shot BB gun ( orange)are all the same dimensions that I can tell, from what I have been working with.

I think the biggest problem most builders will face is the question of making the gun hollow or solid, as the extra thickness of the casing over the base glock really is only a few mm thick, so its quite thin once over the sides of the Glock....

I hope this is of interest and I will post further shots once I have had another quiet time to work on it !

I've been lurking in the forums to watch peoples amazing work in their builds for the Dredd Movie, and thought I'd post up my current progress on a Lawgiver Mk2 build I am doing.

The basis of this build comes from the original CAD files that I was able to obtain....;-)

The files I had were a low res conversion so although looked ok on screen, were very triangulated.

The downside of this is that this meant they were unable to be ammended, sliced or generally reworked.

So I set to work remodelling over the original files to get real CAD data, this also smoothed up all the faces and gave me modelling that could be adjusted and tweaked.

Although I have a CNC machine of my own, its a 2.5d and working with the files gradually I realised that the best way to handle the build was to 'Old School' it.

I printed out the various shapes and forms and using styrene, built up what I could over a cheapo Glock Airsoft.

This gave me a 'case' which slid over the bulk of the gun and a platform to stick everything to when the time came.

(The original gun is made up from many layers of aluminium panels.....)

I then started to CNC the detail parts.

One thing of interest is that it looks like the original Location of the LCD screen and serial No. was over the rear slide.

The LCD screen seen here was a slightly earlier version based on what reference I could pull from the Net as this part of the LG was not in the orginal file.

Currently the gun is still in component form. I now have STL files of the original rear slide section ( which when the gun fires slid back) . I have yet to start this section based on this new file, although the original work I did in this area is correct, thankfully !

Of interest to anyone tackling their own build, It would seem the gas Blowback ( blue) and the cheaper one-shot BB gun ( orange)are all the same dimensions that I can tell, from what I have been working with.

I think the biggest problem most builders will face is the question of making the gun hollow or solid, as the extra thickness of the casing over the base glock really is only a few mm thick, so its quite thin once over the sides of the Glock....

I hope this is of interest and I will post further shots once I have had another quiet time to work on it !