You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Space Command Clipper Build

- Thread starter SteveNeill

- Start date

- Status

- Not open for further replies.

SteveNeill

Sr Member

Rob it's consistent that's for sure.

steve

steve

SteveNeill

Sr Member

Commander Max

Sr Member

Thanks Steve.

Steve-

You continue to out-do yourself!Thanks for letting us see this.

More importantly-Thanks for the tutorials!

Amazing work!

You continue to out-do yourself!Thanks for letting us see this.

More importantly-Thanks for the tutorials!

Amazing work!

SteveNeill

Sr Member

Thanks guys this was a stretch to get made in 30 days. Tomorrow is 4 weeks exactly. Doug is very happy. Just got the tips to fit. Can't do anymore must sleep!

Steve

Steve

Steve,

Right at the end of video part 25 I was expecting you to pass out cigars. You look like a proud parent. And with good reason. I love the design and it just keeps getting better and better. So glad this show will be mixing practical models along with Mr. Drexler's incredible CGI.

Ted.

Right at the end of video part 25 I was expecting you to pass out cigars. You look like a proud parent. And with good reason. I love the design and it just keeps getting better and better. So glad this show will be mixing practical models along with Mr. Drexler's incredible CGI.

Ted.

SteveNeill

Sr Member

Thanks guys and thanks Ray and Ted!

Steve

Steve

Aztek Dummy

Well-Known Member

Hi Steve, you mention "grease" I think, to act as a barrier for your filler... what kind of grease do you use for that?

Thx~

R

Ryder,

In the past Steve has mentioned vaseline when making resists on the molds, but sometimes he has used spray-on mold release. If I had to guess, I'd go with the petroleum jelly

FlyAndFight

Active Member

It's great to see the actual resin pieces finally fitted together (even if temporary). Excellent job and I can't wait for the next installment(s)!

SteveNeill

Sr Member

Spheric Thor

Sr Member

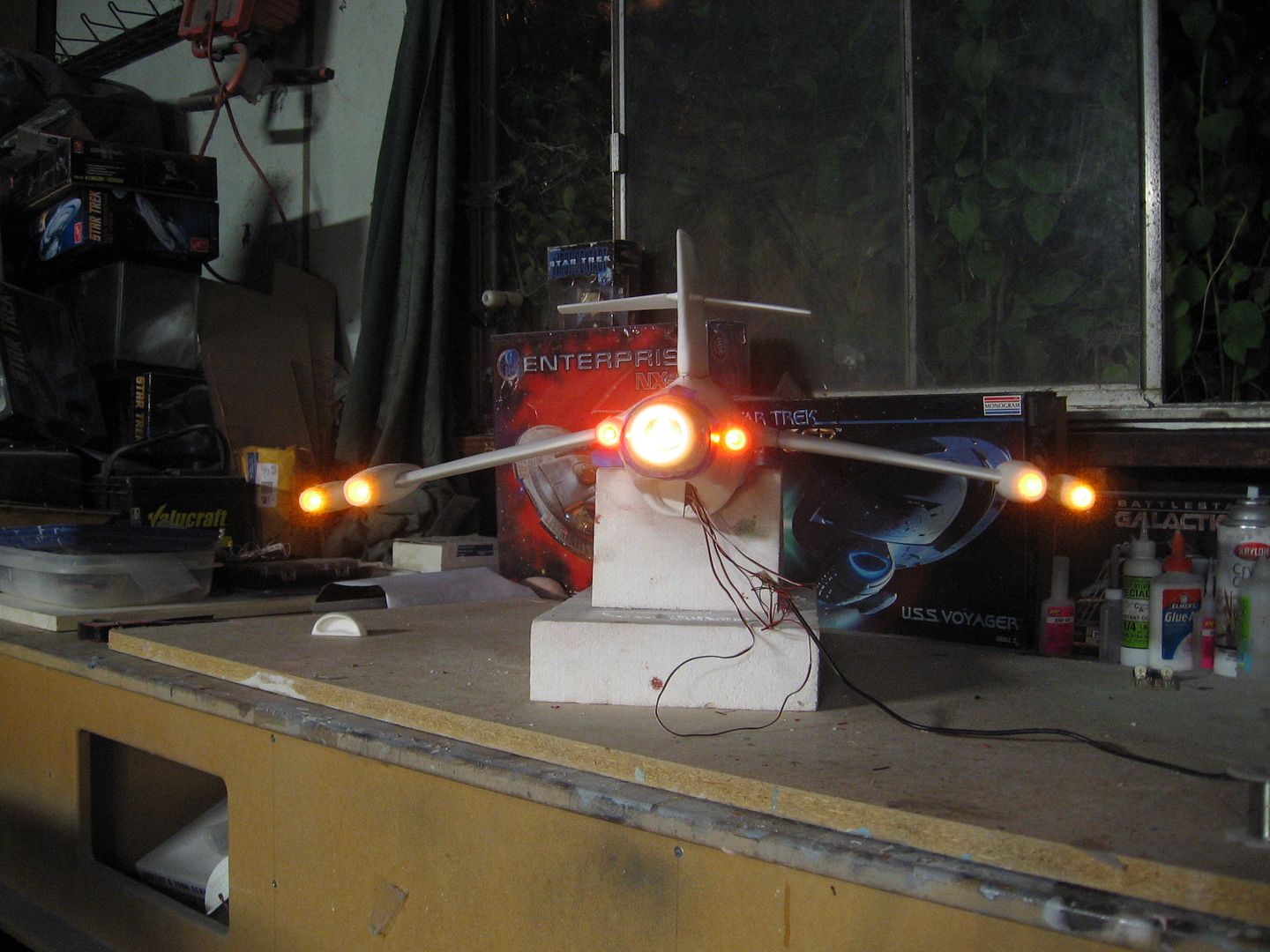

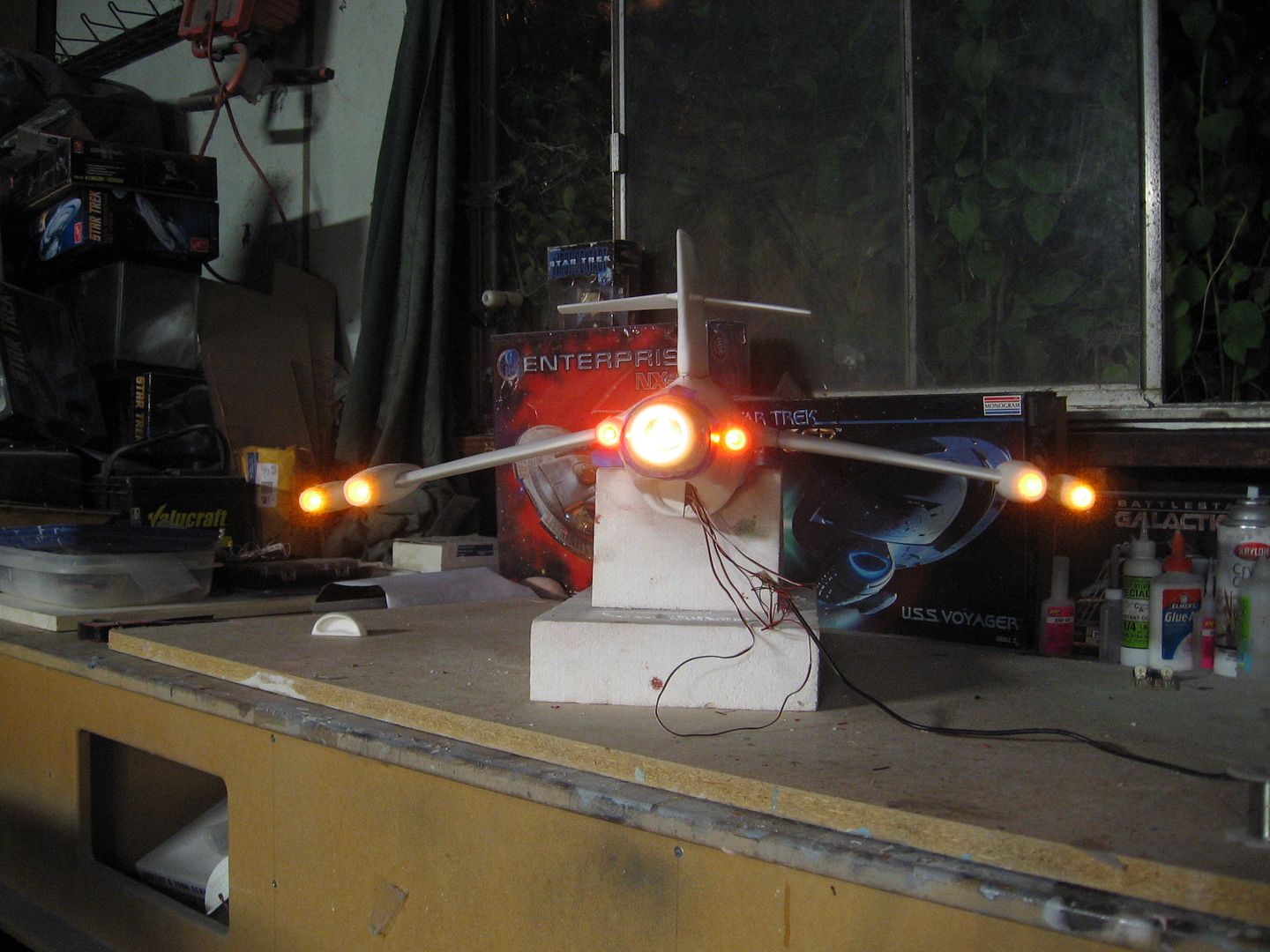

The engine lights look great. When you fired them up I expected to see the ship take off.

SteveNeill

Sr Member

A bit more ignition folks! Video tomorrow.

JP Modelworks

Active Member

The engine lights look great!

- Status

- Not open for further replies.

Similar threads

- Replies

- 35

- Views

- 1,774