It's probably a bit premature to start this thread as for now I only intend to assemble and prime the model. It's too hot here at the moment to go all the way into painting, that will have to wait for later in the year.

That said, I've been finding a few talking points - in case anyone is about to kick off their build, this might be of some use, hopefully. Please note my build is pretty spartan - no lights, no extra mount points, no panavise or ILM/industry-style stand, just a steel rod for the underside mount, and a mahogany base. Much of this won't apply if you intend to create wing mount points:

All for now. There will be pics but has to wait for tomorrow or Monday.

That said, I've been finding a few talking points - in case anyone is about to kick off their build, this might be of some use, hopefully. Please note my build is pretty spartan - no lights, no extra mount points, no panavise or ILM/industry-style stand, just a steel rod for the underside mount, and a mahogany base. Much of this won't apply if you intend to create wing mount points:

- I drilled the main armature rod all the way through using a 7/16 bit in a drill press. It was just a sharp bit that happened to be ready to hand; you could go a little smaller or larger, but it is an ideal size in several respects.

- You could probably do just about as well with a hand drill if you have a good eye and a vise, or can clamp it down well. Centrepunch the location for drilling first off or your drill bit will wander.

- K&H make nice 7/16 brass tubing and stainless steel rods and hopefully your LHS will carry these. I went for stainless, it will need cutting - I hate cutting stainless but it should last forever.

- *Don't* drill the wing bar (if you are only making a lower mount). That will allow the bar to be a stop for the mount rod - it will rest on top of the mount rod and hold the model up. You can just clean off any burring at the cut ends, no need to do more. (Note Jason's excellent instructions give the bar length as 12.5" while mine was slightly smaller. If you are marking the centreline to drill for the upper mount, take note of the exact length of YOUR bar, as it seems they vary - though it shouldn't ultimately vary enough to actually matter. But, you know. We're modelmakers. A bit OCD sometimes. So I thought I'd mention it.) :lol

- That said, DO follow Jason's advise religiously on trimming the fuselage and engine location points for the wing bar. The resin pieces have shrunk slightly, the aluminium ones haven't. You will need to slice and sand out a slight channel in the front or rear (or both) of the fuselage location for the bar in order for it to sit nice and flat. DO sand the horizontal mating surface of the hull, too, as it can be flatter. The same goes for the wing bar location points inside the engines. In all this be sure you don't end up with a loose fit. It's not a structural requirement, it's just that tight fits are always much nicer. Cough.

- Since you aren't using wing mounts, you can slide your engines straight onto the wing bar AFTER assembly. I recommend building the engines first as it will make cleaning up the seams MUCH easier.

- You can also attach all four of the cone shroud support vanes directly to the cone shroud before you assemble it to the engine body. This seems easier than the other method as you can just slide the assembly straight into the back of the Saturn can. Obviously do this BEFORE you start attaching the Plastruct! :lol

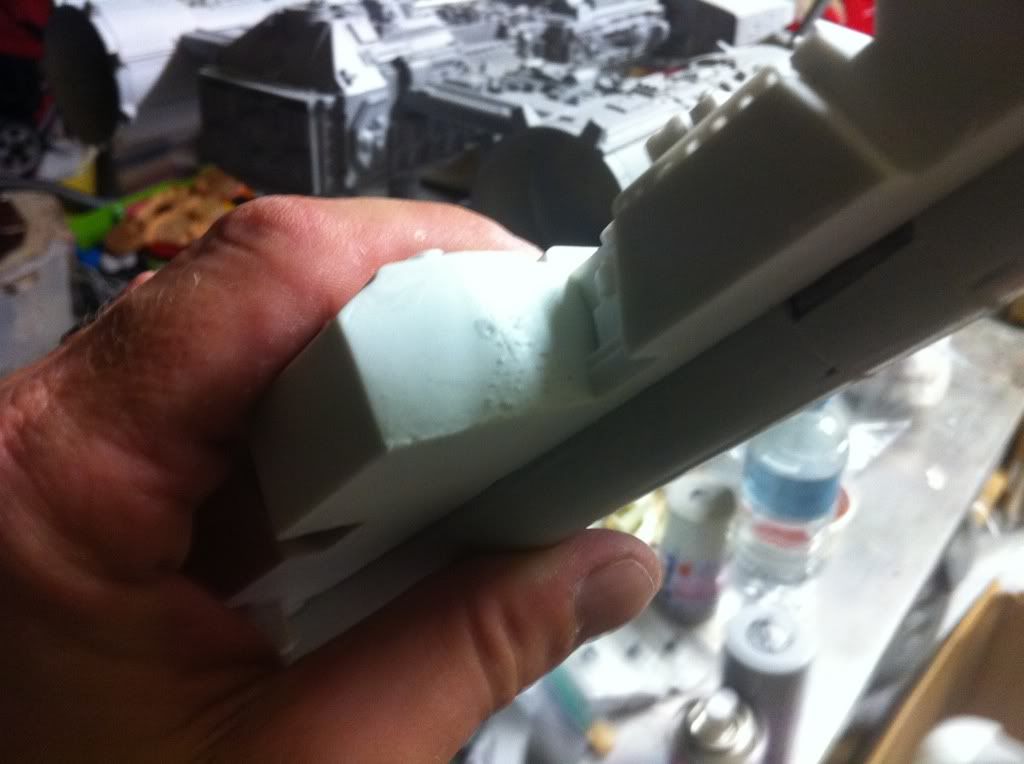

- The support vane thingies are too thick. At least they are to my eyes and a couple of others agree. Not by much but by a little. I am as lazy as a modelmaker can get while still occasionally actually making a model, so I didn't make new ones in styrene. Instead I adzed the trailing edges of the vanes with a single-edged razor blade, then sanded them lightly. Yes, I am THAT lazy.

This took around thirty seconds per vane, only a few passes with a sharp blade does the trick. It's way quicker than cutting 2mm or 3mm styrene replacements would have been.

- When assembled, the conical inserts in the rear of the Saturn cans prevent the seams aligning well along one side, as noted in the instructions. You can shim as described, or you could also try sanding down the conical insert piece around its circumference slightly. I did not do this, but wished I had tried it.

- Another area of poor fit is pointed out in the instructions at the front of one of the Saturn cans. There are little doglegs of flash or pour stubs; this one can be resolved by removing them. Your Saturn can diameter will be slightly smaller so check for fit against the L'Eggs. (But then again, if it fit perfectly it wouldn't be ILM!) :lol

- The wing skins can be made to fit without cutting if you're careful - I THINK - mine did, anyway. Possibly another case of individual variation. I had only the slightest misalignment along the rear tubes, maybe a quarter of a millimetre - well within the putty and sanding range.

- The cockpit rear bulkhead is beautiful but cast in a harder resin. Some details need to be removed, and a circular hole drilled out, as described in the instructions. The ideal tool for this would have to be an end mill bit in a Dremel; don't try to shave the details with Xactos, the resin is too hard. I would LOVE TO KNOW why my LHS and hardware stores haven't carried Dremel end mill bits for years.

Ow, my sliced finger.

All for now. There will be pics but has to wait for tomorrow or Monday.

Last edited: