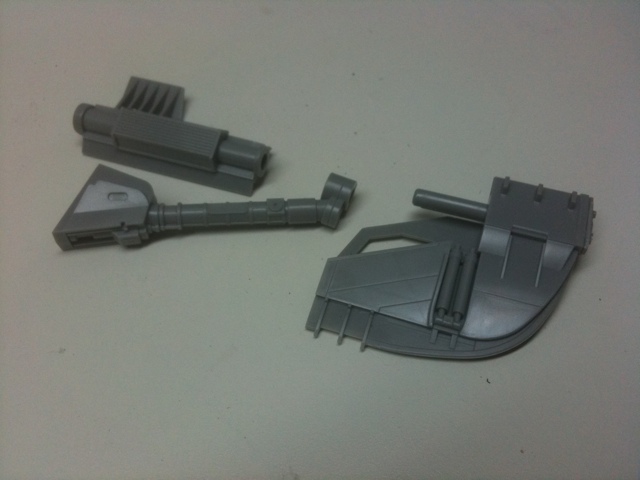

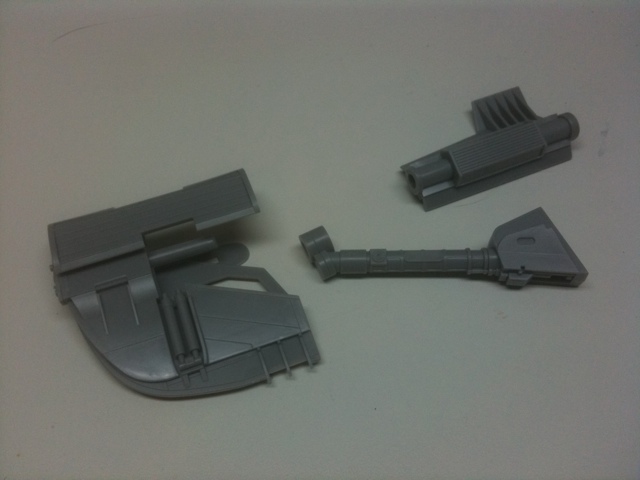

Generally, I think the Fine Mold models are known to be of pretty good accuracy. Obviously, it's not 100% accurate, but I'd say it's pretty close. If you read some of the reviews at Starship Modeler, it rates around a 8.5 out of 10.

Sean

Sean