You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Phaser 1 Kit Buildup plus MM P2 Restoration

- Thread starter asalaw

- Start date

TOS

Active Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Beautifully said..sniff.

Hehehe... What's in a name? That which we call a Trekkie by any other name would smell as sweaty (under the velour costume).

Beautifully said..sniff.

asalaw

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Posting tomorrow. Got a lot done last night, expect to have the handle completed tonight. Here's a little teaser:

And here's another little tidbit I'm working on. When it's finished, I'll post it as a free download.

EDIT: Change of plans. Shop tomorrow, post Tuesday.

EDIT 7/31/15 -- I will definitely return to this, complete it, and post it once I return to the P1 portion of this project.

Posting tomorrow. Got a lot done last night, expect to have the handle completed tonight. Here's a little teaser:

And here's another little tidbit I'm working on. When it's finished, I'll post it as a free download.

EDIT: Change of plans. Shop tomorrow, post Tuesday.

EDIT 7/31/15 -- I will definitely return to this, complete it, and post it once I return to the P1 portion of this project.

Last edited by a moderator:

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

So classic and cool!!!

So classic and cool!!!

And here's another little tidbit I'm working on. When it's finished, I'll post it as a free download.

View attachment 399312

asparagus64

New Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Oh..I can assure you, it's fun for us all to watch your amazing talents at work. Me, I can never get enough of threads like these.

Thanks! Since all three phaser batteries are n-cells, they're all getting the vintage label.This project is incredibly fun across multiple dimensions of funitude!!

Oh..I can assure you, it's fun for us all to watch your amazing talents at work. Me, I can never get enough of threads like these.

asalaw

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Thanks, dude! You're too kind.

OK, well, didn't go to the shop tonight, wasn't gonna post till Tuesday, but a side project appeared in my mailbox and I thought I'd give it a whirl here at home.

Thanks to robn1 (Rob) for discovering what this found part is, and where to find it.

So let's talk about the ol' ten-turn knob. What it is, where it comes from, its likes and dislikes, and hopefully some topless photos.

Plus a bonus! -- I totally ****ed mine up, and you get to learn from it without ruining your own! I know, I'm so incredibly good at making my total bone moves look like I planned it that way... which I did, so STFU!!!!

So what you're looking for is a Kilo Model 462 ten-turn knob.

Here's the link for it on eBay that Rob originally sent me.

There were five of them, but they went fairly quickly -- but you can also get them here, at Allied Electronics, just unfortunately for $26 apiece (probably because they're new from Kilo instead of salvaged).

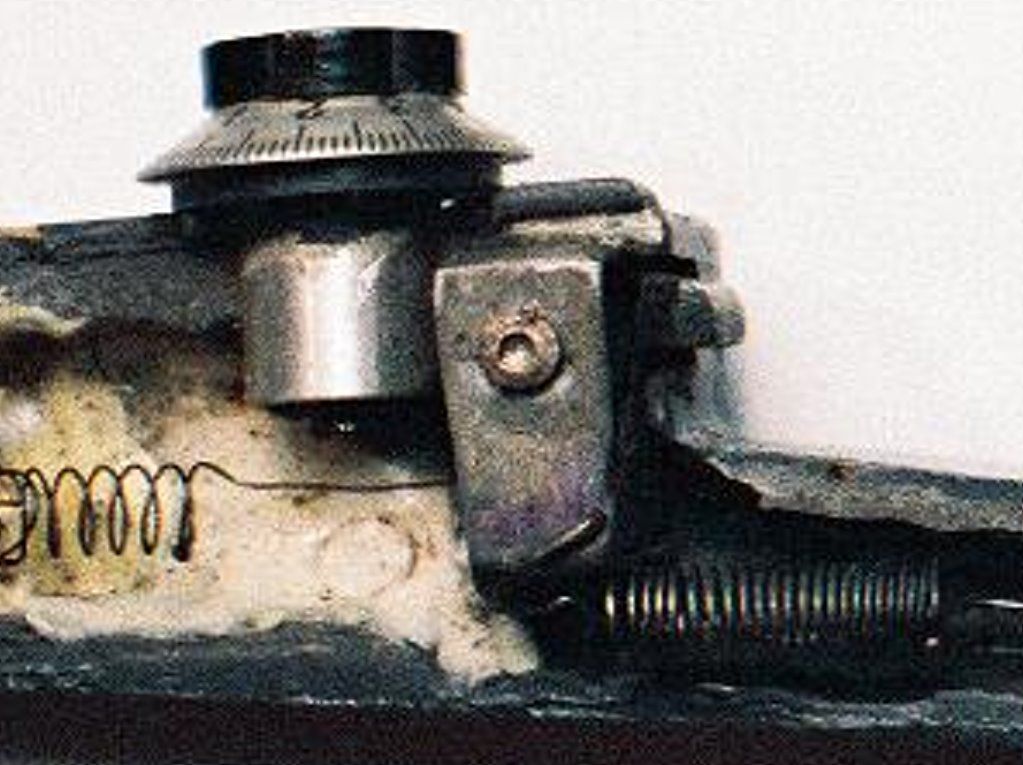

So here's what one looks like attached to a potentiometer, as they're designed to be:

The reason it's called a 10-turn knob is that it counts complete turns of the knob, up to 10 of them, for potentiometers that freely turn past 360 degrees. So if the knob is graduated from 1-10, and you make 4 complete turns, you've actually turned it up to 40. Eat that, Spinal Tap! There are 20-turn knobs, one-turn knobs, 100-turn knobs, you name it. And they're mostly black, look completely wrong, and thus of course they're incredibly cheap all over the Internet. :facepalm

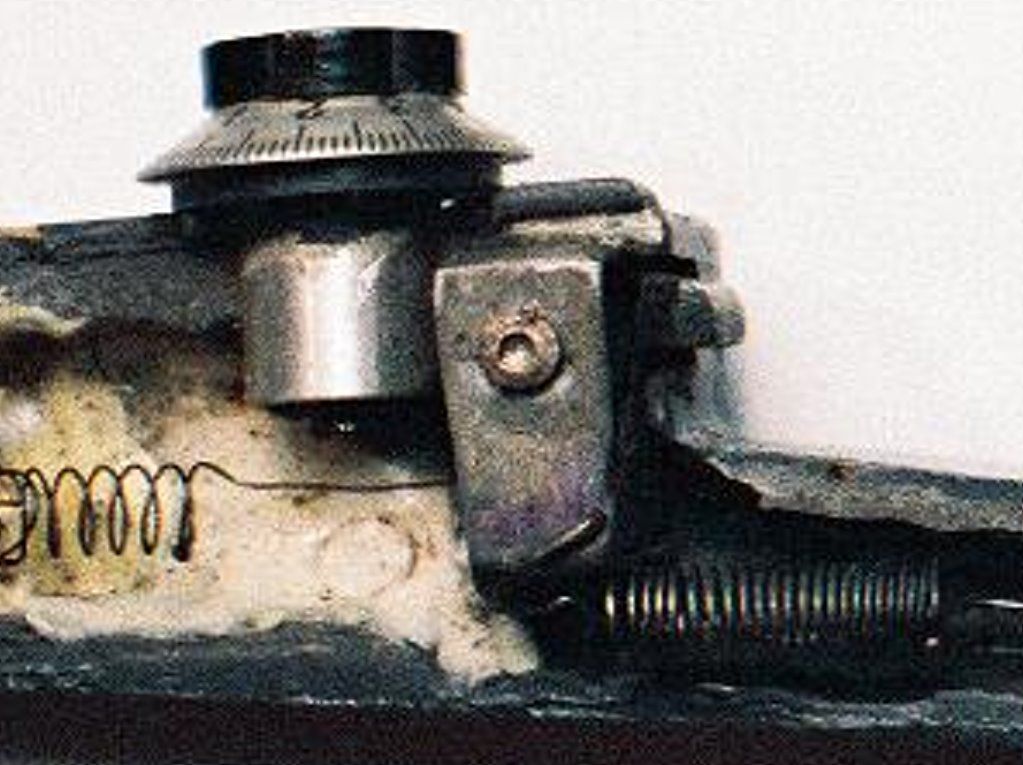

Here it is almost completely taken apart:

That little lever on the large base is for locking the dial in place when you've got the setting you want.

Also, you'll notice a little Allen nut in the side of the knob. Here's what that does:

And finally, if you want to machine your own (why?), or just make yourself a cool phaser diagram, here's the spec sheet from Kilo with everything you always wanted to know about their turn-counting knobs and never thought to ask, because you have better uses for your time...

(A billion free trivia points to whoever is the first to post about the possible use of a different Kilo knob on a different TOS prop! A BILLION!! FREE!!! IS HE CRAZY?!?!?! Hint: It's on the spec sheet. )

)

Okay, so once you have it almost apart, you'll notice one thing: it hates you for wanting to kill it. With victory in sight, that juicy little ten-turn knob in your sweaty little nerd hands, it mocks you. That little knob ain't coming out of the dial skirt for nothin' or nobody. Little aluminum mocking *******. (It's called a skirt, I assume, because it looks just like something from C-3PO's closet.)

So you have to apply some steel persuasion, and here's where I fell down. I figured, this is easy -- set it up on my vise, whack it with a hammer, and presto. I'll put tape on the jaws to prevent marring. And thereby hangs the tale...

See the danger yet? You will...

So here's what I thought would work great as a punch: an allen bit for a screwdriver. It was the right size, the right shape, and most importantly, it was handy.

Next: with a small hammer, start tapping GENTLY!

tap-tap-tap-tap-tap-tap-tap-tap-tap-tap (this will take a couple of minutes) -tap-tap-tap-tap-tap-tap-tap-tap...

And then, DING!!!!

Works like a charm. So here it is, in all its separated glory:

So there you have it, easy as one- WHAT THE ****?!?!?!?! OMG, WTF??!?!?!?!?!?! **** **** **** **** **** **************CK!!!!!!!

I dinged the damn thing. On my vise. With the taped jaws. Soft aluminum, hard steel, and a hammer -- it's a cocktail of death. It has perfectly symmetrical dings, one on either side, where it contacted the vise jaws.

Lesson learned: When my other ones arrive, I'll drill a hole in a block of scrap wood, mount that in the vise, and stick the knob through the hole. Hopefully soft pine from the shop won't ding the way ***KING STEEL DOES, EVEN THROUGH PAPER-THIN MASKING TAPE (who knew?), and I'll get a better result. I think they also make rubber vise covers for just this kind of job. Think I'd better get some...

I think they also make rubber vise covers for just this kind of job. Think I'd better get some...

One final step: there's an eeeeeny weeny pin sticking out of the bottom of the dial skirt, which is part of the turn-counting mechanism. It needs to be yanked out. I used a pair of needle nose pliers and my existential rage left over from screwing up my dial, and it pulled right out.

Okay, tomorrow I'm going to the shop for real, and I'll get the handle finished or very, very close to it, depending on the same God who laughed at my efforts tonight, and what kind of mood he's in tomorrow.

Meanwhile, here's something I also spent some time on tonight:

Thanks, dude! You're too kind.

OK, well, didn't go to the shop tonight, wasn't gonna post till Tuesday, but a side project appeared in my mailbox and I thought I'd give it a whirl here at home.

Thanks to robn1 (Rob) for discovering what this found part is, and where to find it.

So let's talk about the ol' ten-turn knob. What it is, where it comes from, its likes and dislikes, and hopefully some topless photos.

Plus a bonus! -- I totally ****ed mine up, and you get to learn from it without ruining your own! I know, I'm so incredibly good at making my total bone moves look like I planned it that way... which I did, so STFU!!!!

So what you're looking for is a Kilo Model 462 ten-turn knob.

Here's the link for it on eBay that Rob originally sent me.

There were five of them, but they went fairly quickly -- but you can also get them here, at Allied Electronics, just unfortunately for $26 apiece (probably because they're new from Kilo instead of salvaged).

So here's what one looks like attached to a potentiometer, as they're designed to be:

The reason it's called a 10-turn knob is that it counts complete turns of the knob, up to 10 of them, for potentiometers that freely turn past 360 degrees. So if the knob is graduated from 1-10, and you make 4 complete turns, you've actually turned it up to 40. Eat that, Spinal Tap! There are 20-turn knobs, one-turn knobs, 100-turn knobs, you name it. And they're mostly black, look completely wrong, and thus of course they're incredibly cheap all over the Internet. :facepalm

Here it is almost completely taken apart:

That little lever on the large base is for locking the dial in place when you've got the setting you want.

Also, you'll notice a little Allen nut in the side of the knob. Here's what that does:

And finally, if you want to machine your own (why?), or just make yourself a cool phaser diagram, here's the spec sheet from Kilo with everything you always wanted to know about their turn-counting knobs and never thought to ask, because you have better uses for your time...

(A billion free trivia points to whoever is the first to post about the possible use of a different Kilo knob on a different TOS prop! A BILLION!! FREE!!! IS HE CRAZY?!?!?! Hint: It's on the spec sheet.

Okay, so once you have it almost apart, you'll notice one thing: it hates you for wanting to kill it. With victory in sight, that juicy little ten-turn knob in your sweaty little nerd hands, it mocks you. That little knob ain't coming out of the dial skirt for nothin' or nobody. Little aluminum mocking *******. (It's called a skirt, I assume, because it looks just like something from C-3PO's closet.)

So you have to apply some steel persuasion, and here's where I fell down. I figured, this is easy -- set it up on my vise, whack it with a hammer, and presto. I'll put tape on the jaws to prevent marring. And thereby hangs the tale...

See the danger yet? You will...

So here's what I thought would work great as a punch: an allen bit for a screwdriver. It was the right size, the right shape, and most importantly, it was handy.

Next: with a small hammer, start tapping GENTLY!

tap-tap-tap-tap-tap-tap-tap-tap-tap-tap (this will take a couple of minutes) -tap-tap-tap-tap-tap-tap-tap-tap...

And then, DING!!!!

Works like a charm. So here it is, in all its separated glory:

So there you have it, easy as one- WHAT THE ****?!?!?!?! OMG, WTF??!?!?!?!?!?! **** **** **** **** **** **************CK!!!!!!!

I dinged the damn thing. On my vise. With the taped jaws. Soft aluminum, hard steel, and a hammer -- it's a cocktail of death. It has perfectly symmetrical dings, one on either side, where it contacted the vise jaws.

Lesson learned: When my other ones arrive, I'll drill a hole in a block of scrap wood, mount that in the vise, and stick the knob through the hole. Hopefully soft pine from the shop won't ding the way ***KING STEEL DOES, EVEN THROUGH PAPER-THIN MASKING TAPE (who knew?), and I'll get a better result.

One final step: there's an eeeeeny weeny pin sticking out of the bottom of the dial skirt, which is part of the turn-counting mechanism. It needs to be yanked out. I used a pair of needle nose pliers and my existential rage left over from screwing up my dial, and it pulled right out.

Okay, tomorrow I'm going to the shop for real, and I'll get the handle finished or very, very close to it, depending on the same God who laughed at my efforts tonight, and what kind of mood he's in tomorrow.

Meanwhile, here's something I also spent some time on tonight:

Last edited by a moderator:

robn1

Master Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

I did not identify the ten turn, I just found the ebay dealer with the engraved ones.

I don't know what other knob may have been used, but I think it's possible the ten turn knob was mounted to the bottom of the dial. The piece in this pic appears to have the same knurling on the top.

I did not identify the ten turn, I just found the ebay dealer with the engraved ones.

I don't know what other knob may have been used, but I think it's possible the ten turn knob was mounted to the bottom of the dial. The piece in this pic appears to have the same knurling on the top.

asalaw

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Sorry, Rob, didn't mean to accidentally slur your good name.

It's not knurling, it's paint overspray (the dial part probably was out when they painted it). Also, that cylinder is much narrower than the actual knob is, and in fact it's very nearly, if not exactly, the diameter of the inner shaft of the knob. It occurs to me that you could turn the knob down on a lathe to that diameter (to make more room for the P1 catch in front of it), drill a hole in the top, and run your screw through that to hold on the knob. Then you glue the aluminum shaft into place as we've seen, and the knob turns freely.

I'm on the lathe today to turn down my nuts (I hope that won't be as painful as it sounds), so I'll give it a shot. What the hell, all I can do is slowly shave my fingers off, right?

Of course there's one more possibility. On the B&W heroes, that's exactly where the little stubby aluminum knob was. Wah might have removed it, drilled a hole in it, and parked it all the way down in the hole to accommodate the 10-turn. And who knows, maybe it was another Kilo knob, without the skirt part, with the knurling turned down. Or not. We'll probably never know.

Hey, just for chuckles, here's the Google patent search on the original 10-turn knob, complete with patent diagrams showing how the whole mechanism works. Now you'll know more about that thing than Wah probably did.

Sorry, Rob, didn't mean to accidentally slur your good name.

It's not knurling, it's paint overspray (the dial part probably was out when they painted it). Also, that cylinder is much narrower than the actual knob is, and in fact it's very nearly, if not exactly, the diameter of the inner shaft of the knob. It occurs to me that you could turn the knob down on a lathe to that diameter (to make more room for the P1 catch in front of it), drill a hole in the top, and run your screw through that to hold on the knob. Then you glue the aluminum shaft into place as we've seen, and the knob turns freely.

I'm on the lathe today to turn down my nuts (I hope that won't be as painful as it sounds), so I'll give it a shot. What the hell, all I can do is slowly shave my fingers off, right?

Of course there's one more possibility. On the B&W heroes, that's exactly where the little stubby aluminum knob was. Wah might have removed it, drilled a hole in it, and parked it all the way down in the hole to accommodate the 10-turn. And who knows, maybe it was another Kilo knob, without the skirt part, with the knurling turned down. Or not. We'll probably never know.

Hey, just for chuckles, here's the Google patent search on the original 10-turn knob, complete with patent diagrams showing how the whole mechanism works. Now you'll know more about that thing than Wah probably did.

Last edited:

robn1

Master Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Nice find on the patent. I looked a little further, look at the knob on this one http://www.google.com/patents/US280...a=X&ei=3NBXVL_1I8eGyATX5IL4DQ&ved=0CAoQ6AEwAg

Nice find on the patent. I looked a little further, look at the knob on this one http://www.google.com/patents/US280...a=X&ei=3NBXVL_1I8eGyATX5IL4DQ&ved=0CAoQ6AEwAg

asalaw

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Awesome!!!!!

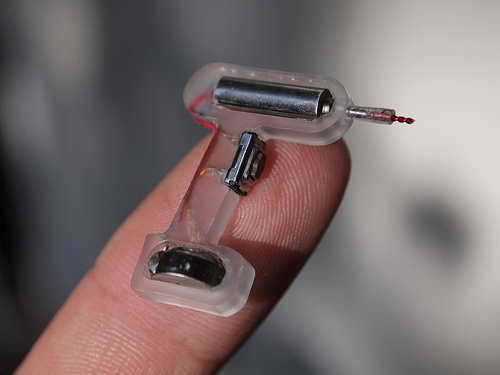

So, here's the same link Rob just posted, only bigger!!! And redder!!!!!

Awesome!!!!!

So, here's the same link Rob just posted, only bigger!!! And redder!!!!!

Last edited by a moderator:

asalaw

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Hey everybody!!

Fresh from two sessions at the shop (well, maybe not "fresh"-- I'm pretty frakkin' tired), and I've had quite an education in the last three or four days. I've learned how not to liberate the skirt on a Kilo knob (see above), but also even more crazy stuff about the original handle that I'm about to spill. It's about to gush phaser handle goodness all up in here.

Had a long (looooooong) talk with John last night. He confirmed some things, corrected some things, and reminded me of a bunch of information I'd forgotten. He's doing great by the way, thanks for asking.

So let's start with this one: I was discussing the origin of the brass end plate with asparagus64 when I remembered that the handles were supposed to stack together for more power, so I tried this:

Whoah, there, buddy! Don't I get dinner first?

I couldn't remember at the time where this idea came from, except that it was on the old boards. Turns out it was John who posted that stuff way back when he examined GJ's phaser, and he noticed the similarity between the butterfly hole on the plate and the shape of the female connector on the pistol. That was exactly what reminded me of this in the first place -- I had the handle out and was going through my various parts (I was also checking out stuff for the phaser ) when I noticed the female Bakelite connector I have and the end plate have the same form. So I tried it, and Bob's your uncle and Fanny's your aunt.

) when I noticed the female Bakelite connector I have and the end plate have the same form. So I tried it, and Bob's your uncle and Fanny's your aunt.

Then John told me something I didn't remember at all -- when you twist the handle prongs into the butterfly hole (the butterfly hole on the butt plate... hehehehe... I said "plate"...), the handle locks into perfect alignment with it. So I tried that too, and...

And now Bob's your gay uncle and Aunt Fannie's divorcing him.

Hard to tell from this photo, but I'm about two minutes with a mini-file away from perfect alignment.

I cannot emphasize enough that I did not design for this or plan for it. I half-remembered it after the fact, and confirmed it just by using parts that I'd measured pretty carefully for, and refined with accuracy in mind. And yet it's a perfect fit.

So, despite what asparagus64 and I discussed about the lock plate maybe being a found item, it's not. He found an auction for some vintage lock plates that look very similar (and hopefully he'll post it here...), but I think this was yet another case of Wah taking a design from similar things in the world around him. Was was an artist, and that's what they do.

John examined that phaser very carefully, took it apart, reassembled it, took pictures, notes, measurements, and also licked it to see if he'd get high. Only some of that is made up.

Anyway, he was convinced then and still is that both the end plate and the tang nut were scratch-made, which brings me to my nuts. The tangy ones.

So, long story short, here's where I am now with the handle parts:

I know, I know, I said I'd finish the handle yesterday. I was younger then, and so jejune... ah, youth...

My self-image when I said that:

My phaser handle's gonna be SO ***king cool!!

And my actual appearance taken by an independent photographer...

I can see the back of my teeth from here!

One of the things I keep re-learning is what John said almost 15 years ago: this thing is a lot of work. Every little item is a huge job. And the handle is numerous little items.

What was I saying? Oh yeah--my nuts.

When I measured the tang nuts I got from these Knife Kits.com guys, who also supply cheap kydex in small cuts for holsters and knife sheaths, I realized I'd have to machine it down to size and cut it down to fit under the end plate. They also have cheap slow-boat postage available, so they're a pretty economical supplier. [EDIT -- Forgot to thank Robn1 for the tang nut link!] Yay! And also not yay.

Because re-sizing that thing is a bear. The biggest challenge in machining anything, on a lathe or a mill, is work holding. If your work isn't properly secured and correctly oriented relative to the rotation of the tooling, you can have any of a range of disasters from just breaking your tooling to becoming instant zombie food.

And holding a piece when you're going to turn it down along its entire length can be a pain, especially if it's very small...

Because ***king huge lathe.

By the way, that's after I was done and cleaned up. I've always worked that way, but now they've put up signs.

Because too many a$sh0le$.

So in the end, between the work slipping under my tooling, or actually coming to a dead stop with the chuck still turning at 1800rpm (never a good sign), and even though I got a great piece out of it, I'm just going to make my own from scratch from now on. I can definitely say from experience that scratch-turning your own nuts is just plain easier than trying to make a silk purse from a sow's ear. (By the way, from "turning your own nuts" and "silk purse from a sow's ear," all I got is jokes involving Frankenstein, farm animals, and lots of lubricant, so never mind. Not going there.)

John never found it believable that anything on the phaser was found, except for the diamond-embossed material on the P1, the Hubbell plugs, and of course the Kilo dial. Having gone through this ordeal myself now, I am absolutely convinced that the tang nut was not a found item, and it's far easier to just make one than to try to convert something that's already too short to chuck properly.

And since we're talking so freely and openly about nuts and butts (because we're all post-Dr. Ruth modern folk, plus perverts), let's get into the butt plug, and how it connects to the batteries that go inside the handle to power the little GOW bulb in the... uh... extending tip... (Okay, I'm saying it. Wah was a total perv. Just look at all the butts and nuts and tips everywhere! It's like a Roman sausage-fest in here!)

Hey everybody!!

Fresh from two sessions at the shop (well, maybe not "fresh"-- I'm pretty frakkin' tired), and I've had quite an education in the last three or four days. I've learned how not to liberate the skirt on a Kilo knob (see above), but also even more crazy stuff about the original handle that I'm about to spill. It's about to gush phaser handle goodness all up in here.

Had a long (looooooong) talk with John last night. He confirmed some things, corrected some things, and reminded me of a bunch of information I'd forgotten. He's doing great by the way, thanks for asking.

So let's start with this one: I was discussing the origin of the brass end plate with asparagus64 when I remembered that the handles were supposed to stack together for more power, so I tried this:

Whoah, there, buddy! Don't I get dinner first?

I couldn't remember at the time where this idea came from, except that it was on the old boards. Turns out it was John who posted that stuff way back when he examined GJ's phaser, and he noticed the similarity between the butterfly hole on the plate and the shape of the female connector on the pistol. That was exactly what reminded me of this in the first place -- I had the handle out and was going through my various parts (I was also checking out stuff for the phaser

Then John told me something I didn't remember at all -- when you twist the handle prongs into the butterfly hole (the butterfly hole on the butt plate... hehehehe... I said "plate"...), the handle locks into perfect alignment with it. So I tried that too, and...

And now Bob's your gay uncle and Aunt Fannie's divorcing him.

Hard to tell from this photo, but I'm about two minutes with a mini-file away from perfect alignment.

I cannot emphasize enough that I did not design for this or plan for it. I half-remembered it after the fact, and confirmed it just by using parts that I'd measured pretty carefully for, and refined with accuracy in mind. And yet it's a perfect fit.

So, despite what asparagus64 and I discussed about the lock plate maybe being a found item, it's not. He found an auction for some vintage lock plates that look very similar (and hopefully he'll post it here...), but I think this was yet another case of Wah taking a design from similar things in the world around him. Was was an artist, and that's what they do.

John examined that phaser very carefully, took it apart, reassembled it, took pictures, notes, measurements, and also licked it to see if he'd get high. Only some of that is made up.

Anyway, he was convinced then and still is that both the end plate and the tang nut were scratch-made, which brings me to my nuts. The tangy ones.

So, long story short, here's where I am now with the handle parts:

I know, I know, I said I'd finish the handle yesterday. I was younger then, and so jejune... ah, youth...

My self-image when I said that:

My phaser handle's gonna be SO ***king cool!!

And my actual appearance taken by an independent photographer...

I can see the back of my teeth from here!

One of the things I keep re-learning is what John said almost 15 years ago: this thing is a lot of work. Every little item is a huge job. And the handle is numerous little items.

What was I saying? Oh yeah--my nuts.

When I measured the tang nuts I got from these Knife Kits.com guys, who also supply cheap kydex in small cuts for holsters and knife sheaths, I realized I'd have to machine it down to size and cut it down to fit under the end plate. They also have cheap slow-boat postage available, so they're a pretty economical supplier. [EDIT -- Forgot to thank Robn1 for the tang nut link!] Yay! And also not yay.

Because re-sizing that thing is a bear. The biggest challenge in machining anything, on a lathe or a mill, is work holding. If your work isn't properly secured and correctly oriented relative to the rotation of the tooling, you can have any of a range of disasters from just breaking your tooling to becoming instant zombie food.

Insert video montage of lathe-related pain and suffering here. With dreary Russian depression music. Coming up in November.

EDIT -- 7/27/15 -- Or not, I guess...

And holding a piece when you're going to turn it down along its entire length can be a pain, especially if it's very small...

Because ***king huge lathe.

By the way, that's after I was done and cleaned up. I've always worked that way, but now they've put up signs.

Because too many a$sh0le$.

So in the end, between the work slipping under my tooling, or actually coming to a dead stop with the chuck still turning at 1800rpm (never a good sign), and even though I got a great piece out of it, I'm just going to make my own from scratch from now on. I can definitely say from experience that scratch-turning your own nuts is just plain easier than trying to make a silk purse from a sow's ear. (By the way, from "turning your own nuts" and "silk purse from a sow's ear," all I got is jokes involving Frankenstein, farm animals, and lots of lubricant, so never mind. Not going there.)

John never found it believable that anything on the phaser was found, except for the diamond-embossed material on the P1, the Hubbell plugs, and of course the Kilo dial. Having gone through this ordeal myself now, I am absolutely convinced that the tang nut was not a found item, and it's far easier to just make one than to try to convert something that's already too short to chuck properly.

(I'll be doing a "part 2" video showing how to make one from scratch at a later date, and I'm going to insert it here as a companion to the tangy frustration/Russian dirge video link that will appear above very soon. So watch for this box to disappear in November and be replaced by the video.)

Edit -- 7/27/15 -- I will be putting in a video here on how to turn a tang nut... once I've turned one... some day...

And since we're talking so freely and openly about nuts and butts (because we're all post-Dr. Ruth modern folk, plus perverts), let's get into the butt plug, and how it connects to the batteries that go inside the handle to power the little GOW bulb in the... uh... extending tip... (Okay, I'm saying it. Wah was a total perv. Just look at all the butts and nuts and tips everywhere! It's like a Roman sausage-fest in here!)

Last edited by a moderator:

spacerone

Well-Known Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Aureliano I have seen this done once before at Tony's website where one handle connects to the bottom of another.

I thought it was a cool idea when I first saw it a few years ago.

Here is a picture I got from his site.

Talking about extra power.

So let's start with this one: I was discussing the origin of the brass end plate with asparagus64 when I remembered that the handles were supposed to stack together for more power, so I tried this:

Aureliano I have seen this done once before at Tony's website where one handle connects to the bottom of another.

I thought it was a cool idea when I first saw it a few years ago.

Here is a picture I got from his site.

Talking about extra power.

redshirt

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Awesome! Thanks for sharing.

I am loving this thread ASA

I have not dug out my box full of phasers in a long time.

Considering what you are working on i figured you would appreciate this blast from the ASAP days.

Man, my iPad camera never takes a good pic of anything :unsure

View attachment 396995View attachment 396996View attachment 396997

Awesome! Thanks for sharing.

asalaw

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

Nice build, phez!

Ooookee-dokey... where was I?

Oh yeah. Train still waiting at Handletown, but the conductor is warming up the fat lady's pipes. She seems to be enjoying it.

So here's a quick rundown of the progress on the handle.

First, it was FINALLY time to file out the damn new end plate for the handle. This is very time-consuming. I've identified ways to make the overall process of making the plate go easier, but not much quicker. Next time I sit down to hand-make these, I'm going to just drill out the center holes on the mill, then file out the butterfly hole (no matter how much the butterfly screams), then go back and drill and countersink the edge holes. Leaned that -- say it with me boys and girls! -- the hard way.

But frankly, I'm only going to hand-make maybe one more, tops. Not doing this **** for a houseful of phasers. Paging Dr. Tormach...

I took some lovely time lapse of the process, and just setting that up took a little time because I forgot my tripod and had to wing the setup:

Techshop -- now with even more assloads of scrap!!

Update!!!! Time-lapse video is finished and now down to one minute!!

(Please remember I wasn't really going that fast. Just movie magic. You can put away your torches and pitchforks. )

)

And here's what I ended up with after filing down to the laser marks:

And this is what your phaser looks like after you stop for a paint fumes break!

And the ol' red Sharpie trick:

Red Sharpie -- for that slutty phaser in your life!

And finally:

Somewhere a song was playing... Handel! Handel's phaser -- um, Messiah! Nah. Pink Floyd. Time and Money. My parenting was one huge mistake.

Now we get to a bit of a mystery -- WTF happened to GJ's butt plug? Somebody put springs on it (OW!)! It used to be all like

And now it's all like

John asked GJ about this, and it turns out the person who took this picture attempted to make it work again. A noble effort, but now it looks like Katy Perry's prom dress.

I'm an expert on prom dresses. But really, who isn't?

So, after brushing aside my memories of teenage car parking (and that took a lot of brushing), I went with the original look. Cuz who wants to just glue on a couple of battery springs when you can make your fingertips look like sushi scraps by cutting and shaping really thin brass? Hah! -- I thought so.

So I grabbed my little brass strips from a previous session (which is done by reaching your whole arm deep into your iPad while it's playing an episode of Sliders) and went to town:

That screw is there just to hold it in place while I bend it. There's a nut on the bottom.

The holes are done on the shop metal puncher with a 1/4" metal punch. Not to be confused with any cowboy stuff.

Kit West declined a request for an interview. Because boobs.

Truth be told, Kit West is kind of a mean drunk...

Expected to testify.

I did the shaping on a huge disk sander in the metal shop -- seriously, it's like two feet wide with 80 grit on it. I tried the grinding wheel first, but that was far too aggressive and just chewed up my metal and filled me with angst.

The batsh!t German kind.

Anyhoo...

I tried this new tool (40% off with a coupon at Michaels, I think I paid like 5 bucks), and it worked fine, but with sheet (as opposed to wire) it's better for compound bends. I got very nice results just bending it around a mini-screwdriver.

Same size as my cold, black heart. I've never been to Whoville.

After a couple of attempts, here's what I have now:

Important note thingy: You'll notice the brass is still nice and shiny. That's because I didn't anneal it. DON'T anneal the brass for this piece. You want it springy -- it's a battery terminal!

And that's it for tonight. Back soon with the assembly (FINALLY!! YAAAAY!!!!) of the handle internals, followed by the final (FINAL!!!! YAAAAAY!!!) painting and finishing of the handle.

Once the handle is completely finished and painted (and I drop dead from exhaustion and German angst), I'm going to take a couple of weeks off from this project. I've been eating, sleeping, and breathing phasers for a month now (seriously -- ever tried passing a phaser? It feels like nuclear Chipotle lava). During that time, I'm going to catch up on a few things that have been piling up -- stuff like my web site design, a ton of phaser video editing and posting, finishing my brass query to that metallurgist friend, journaling this build for future reference, and getting reacquainted with this lady I first hooked up with in the Dim Time.

These are my ears for Wife.

You know, stuff.

Nice build, phez!

Hey! There ya go -- and now we know where the idea comes from. It's been out there for so long, nobody remembered, including me.Aureliano I have seen this done once before at Tony's website where one handle connects to the bottom of another.

I thought it was a cool idea when I first saw it a few years ago. -- Spacerone

Ooookee-dokey... where was I?

Oh yeah. Train still waiting at Handletown, but the conductor is warming up the fat lady's pipes. She seems to be enjoying it.

So here's a quick rundown of the progress on the handle.

First, it was FINALLY time to file out the damn new end plate for the handle. This is very time-consuming. I've identified ways to make the overall process of making the plate go easier, but not much quicker. Next time I sit down to hand-make these, I'm going to just drill out the center holes on the mill, then file out the butterfly hole (no matter how much the butterfly screams), then go back and drill and countersink the edge holes. Leaned that -- say it with me boys and girls! -- the hard way.

But frankly, I'm only going to hand-make maybe one more, tops. Not doing this **** for a houseful of phasers. Paging Dr. Tormach...

I took some lovely time lapse of the process, and just setting that up took a little time because I forgot my tripod and had to wing the setup:

Techshop -- now with even more assloads of scrap!!

Update!!!! Time-lapse video is finished and now down to one minute!!

(Please remember I wasn't really going that fast. Just movie magic. You can put away your torches and pitchforks.

And here's what I ended up with after filing down to the laser marks:

And this is what your phaser looks like after you stop for a paint fumes break!

And the ol' red Sharpie trick:

Red Sharpie -- for that slutty phaser in your life!

And finally:

Somewhere a song was playing... Handel! Handel's phaser -- um, Messiah! Nah. Pink Floyd. Time and Money. My parenting was one huge mistake.

Now we get to a bit of a mystery -- WTF happened to GJ's butt plug? Somebody put springs on it (OW!)! It used to be all like

And now it's all like

John asked GJ about this, and it turns out the person who took this picture attempted to make it work again. A noble effort, but now it looks like Katy Perry's prom dress.

I'm an expert on prom dresses. But really, who isn't?

So, after brushing aside my memories of teenage car parking (and that took a lot of brushing), I went with the original look. Cuz who wants to just glue on a couple of battery springs when you can make your fingertips look like sushi scraps by cutting and shaping really thin brass? Hah! -- I thought so.

So I grabbed my little brass strips from a previous session (which is done by reaching your whole arm deep into your iPad while it's playing an episode of Sliders) and went to town:

That screw is there just to hold it in place while I bend it. There's a nut on the bottom.

The holes are done on the shop metal puncher with a 1/4" metal punch. Not to be confused with any cowboy stuff.

Kit West declined a request for an interview. Because boobs.

Truth be told, Kit West is kind of a mean drunk...

Expected to testify.

I did the shaping on a huge disk sander in the metal shop -- seriously, it's like two feet wide with 80 grit on it. I tried the grinding wheel first, but that was far too aggressive and just chewed up my metal and filled me with angst.

The batsh!t German kind.

Anyhoo...

I tried this new tool (40% off with a coupon at Michaels, I think I paid like 5 bucks), and it worked fine, but with sheet (as opposed to wire) it's better for compound bends. I got very nice results just bending it around a mini-screwdriver.

Same size as my cold, black heart. I've never been to Whoville.

After a couple of attempts, here's what I have now:

Important note thingy: You'll notice the brass is still nice and shiny. That's because I didn't anneal it. DON'T anneal the brass for this piece. You want it springy -- it's a battery terminal!

And that's it for tonight. Back soon with the assembly (FINALLY!! YAAAAY!!!!) of the handle internals, followed by the final (FINAL!!!! YAAAAAY!!!) painting and finishing of the handle.

Once the handle is completely finished and painted (and I drop dead from exhaustion and German angst), I'm going to take a couple of weeks off from this project. I've been eating, sleeping, and breathing phasers for a month now (seriously -- ever tried passing a phaser? It feels like nuclear Chipotle lava). During that time, I'm going to catch up on a few things that have been piling up -- stuff like my web site design, a ton of phaser video editing and posting, finishing my brass query to that metallurgist friend, journaling this build for future reference, and getting reacquainted with this lady I first hooked up with in the Dim Time.

These are my ears for Wife.

You know, stuff.

Last edited by a moderator:

redshirt

Sr Member

Re: John Long Phaser 1 Kit Buildup plus MM P2 Restoration

I'll second that. Informing and fun. I'm waiting for the next update with more excitement than Justin Long at a Galaxy Quest convention.

Love your updates. Perfect amount of giggle and tech. Btw that was my college nickname.

I'll second that. Informing and fun. I'm waiting for the next update with more excitement than Justin Long at a Galaxy Quest convention.

Similar threads

- Replies

- 10

- Views

- 1,148