Someone said something about a steel dagger blade... :confused

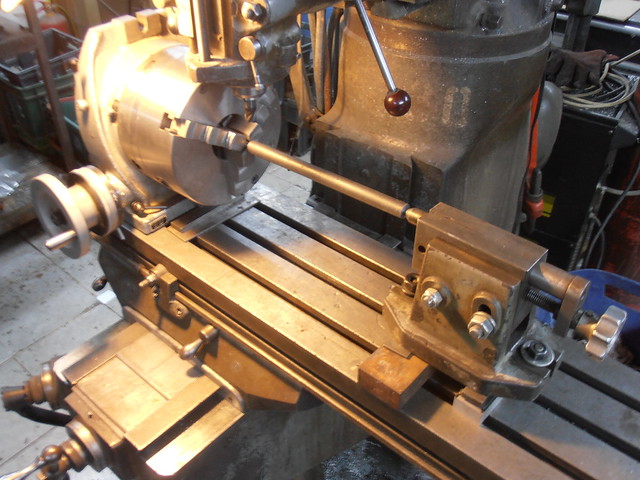

The blade starts out at 18mm dia. x 310mm steel blank.

I put them on the lathe, face each side, drill in center points, then take down a 64mm section of one end to 6mm and add 4 key grooves.

**Don't try this at home... I'm a professional ... no seriously, don't try this I'm a bit crazy.

... no seriously, don't try this I'm a bit crazy.

The angle needed to taper the dagger blade is ever so slight that it took some trial and error and lots of playing with shims under the dividing head to get it right. One error resulted in a snag that broke the 16mm carbide End Mill I was using. I ended up buying 2 new ones and modifying a drill sharpener I have to sharpen the carbide end mills. I resharpened the broken one first to test and it cut the steel like butter again.

Lovely thing about using carbide, the bits flying off are so hot they stick to skin... especially soft, exposed facial skin and burns facial hair. I can still smell the hair burnin. :lol

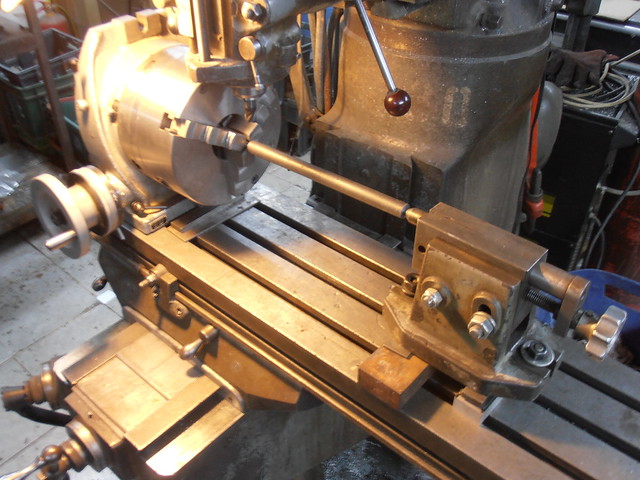

Here's a finished blade after cutting off the extra bit that the center point sits in and put back in the chuck. On the finial side, after a certain point, the cuts had to be moderate to light to keep things from snagging since it's only about 4mm.

And here's a machine-finished steel dagger of Megiddo blade. I then sanded each side by hand to get it to a 3mm tip. These things are very sharp.

The blade starts out at 18mm dia. x 310mm steel blank.

I put them on the lathe, face each side, drill in center points, then take down a 64mm section of one end to 6mm and add 4 key grooves.

**Don't try this at home... I'm a professional

The angle needed to taper the dagger blade is ever so slight that it took some trial and error and lots of playing with shims under the dividing head to get it right. One error resulted in a snag that broke the 16mm carbide End Mill I was using. I ended up buying 2 new ones and modifying a drill sharpener I have to sharpen the carbide end mills. I resharpened the broken one first to test and it cut the steel like butter again.

Lovely thing about using carbide, the bits flying off are so hot they stick to skin... especially soft, exposed facial skin and burns facial hair. I can still smell the hair burnin. :lol

Here's a finished blade after cutting off the extra bit that the center point sits in and put back in the chuck. On the finial side, after a certain point, the cuts had to be moderate to light to keep things from snagging since it's only about 4mm.

And here's a machine-finished steel dagger of Megiddo blade. I then sanded each side by hand to get it to a 3mm tip. These things are very sharp.