Gattaca

Well-Known Member

Just thought I would cut and paste this from my blog to help out anyone who wants to learn how to make molds and casts.

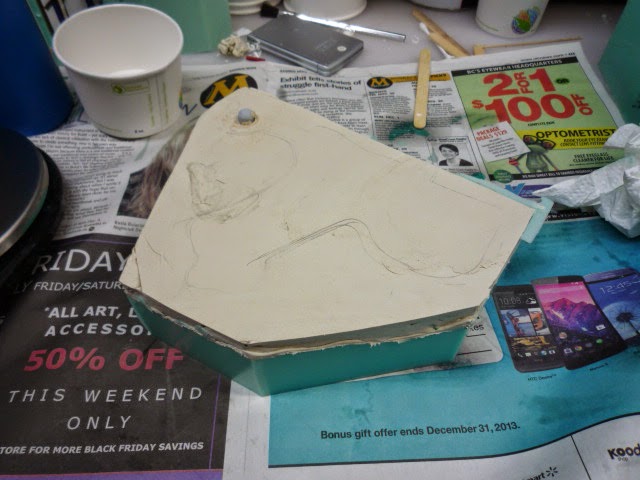

I'm going to go through the steps of molding and casting a prop part. In this case it's the gun grip for my DLT 19 blaster. I made the original part from MDF, then primed and sanded it smooth.

The part needs to be buried about half way up in Plasticine. Make sure the

The part needs to be buried about half way up in Plasticine. Make sure the

Plasticine you use is compatible with your molding material.

[

Smooth out the Plasticine as you go, and make sure you get a nice smooth seal around the object.

Trim the Plasticine to a minimum of 1/2 an inch around the object.

Trim the Plasticine to a minimum of 1/2 an inch around the object.

I plan on filling the mold from the bottom of the hand grip, or upside down. I'll need to allow any trapped air out as this happens. I've marked my paths for the air vents.

I plan on filling the mold from the bottom of the hand grip, or upside down. I'll need to allow any trapped air out as this happens. I've marked my paths for the air vents.

I'm using 1.5mm styrene rods, but you can use wax or some other rod type material, as long as it's not porous. You don't want the rubber to stick to it. Make sure the rod you use is well seated into the Plasticine so no rubber can get under it.

I'm using 1.5mm styrene rods, but you can use wax or some other rod type material, as long as it's not porous. You don't want the rubber to stick to it. Make sure the rod you use is well seated into the Plasticine so no rubber can get under it.

A good tip is to create a groove around the perimeter of the object. This will help 'key' the two halves together as well as create a better seal.

A good tip is to create a groove around the perimeter of the object. This will help 'key' the two halves together as well as create a better seal.

You can see in this image how my vents will work to let air rise out the top of the mold. Any high spot will create an air 'pocket'. The ball bearings act as 'keys', they will be removed before molding the second half.

You can see in this image how my vents will work to let air rise out the top of the mold. Any high spot will create an air 'pocket'. The ball bearings act as 'keys', they will be removed before molding the second half.

I've built a box from scraps of foam core, held together in the corners with hot glue. The bottom edge is also glued in a few spots to keep it in place. Make sure you have a good seal, you don't want all or even some of your rubber to leak out. Keep in mind you will need to use this box again.

I've built a box from scraps of foam core, held together in the corners with hot glue. The bottom edge is also glued in a few spots to keep it in place. Make sure you have a good seal, you don't want all or even some of your rubber to leak out. Keep in mind you will need to use this box again.

After spraying the mold release as per the instructions on the can, you can pour your rubber into the mold. However don't just glob it in like a cake mix, you must pour it in a slow and small stream. This will prevent bubbles being trapped in the mold. Notice the small black line on the inside, that's my fill line, about 1/2 inch above the highest point of the object. I'm using Smooth On's Mold Max 40.

After spraying the mold release as per the instructions on the can, you can pour your rubber into the mold. However don't just glob it in like a cake mix, you must pour it in a slow and small stream. This will prevent bubbles being trapped in the mold. Notice the small black line on the inside, that's my fill line, about 1/2 inch above the highest point of the object. I'm using Smooth On's Mold Max 40.

Let it set up over night.

Let it set up over night.

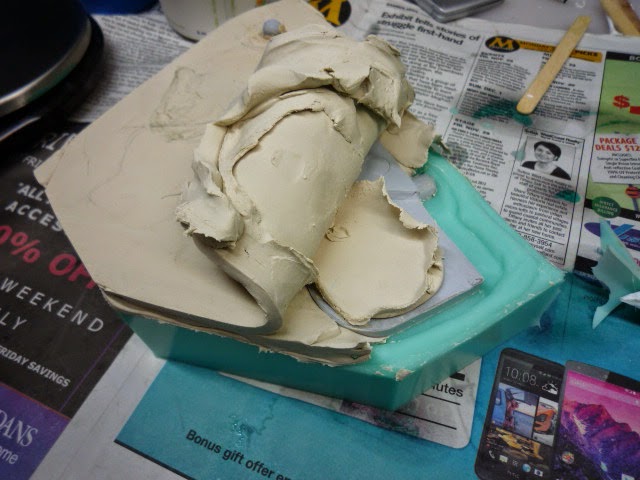

The next day you can carefully open the box by cutting one of the corners and the dabs of glue on the bottom. Then peel the box away from the rubber.

The next day you can carefully open the box by cutting one of the corners and the dabs of glue on the bottom. Then peel the box away from the rubber.

Flip the mold over and remove the base to expose the

Flip the mold over and remove the base to expose the

Plasticine.

Then carefully remove it. Try not to disturb the object or the vents. You can remove the ball bearings.

Then carefully remove it. Try not to disturb the object or the vents. You can remove the ball bearings.

Do your best to remove all the

Do your best to remove all the

Plasticine and any stray bits of rubber. The mold should be clean and smooth.

Re build your box (now up side down) and seal the corner. Apply mold release. I prefer Mann Ease Release 200.

Re build your box (now up side down) and seal the corner. Apply mold release. I prefer Mann Ease Release 200.

Fill the box and let it set up overnight.

Fill the box and let it set up overnight.

You can remove the mold from the box now...

You can remove the mold from the box now...

...and begin to

...and begin to

separate the two halves. You can remove the vents as you go, just be careful not to tear the mold.

Work your way carefully around the object...

Work your way carefully around the object...

...until you

...until you

separate the two halves and can remove the original object. Take some time to inspect the mold, look for any bits of rubber that have crept into places you don't want it, and trim it off.

I've used an Xacto to enlarge the pour hole and cleared the path of the air vents.

I've used an Xacto to enlarge the pour hole and cleared the path of the air vents.

Cut some cardboard to match the shape of the mold, then secure the two halves with elastic bands.

Cut some cardboard to match the shape of the mold, then secure the two halves with elastic bands.

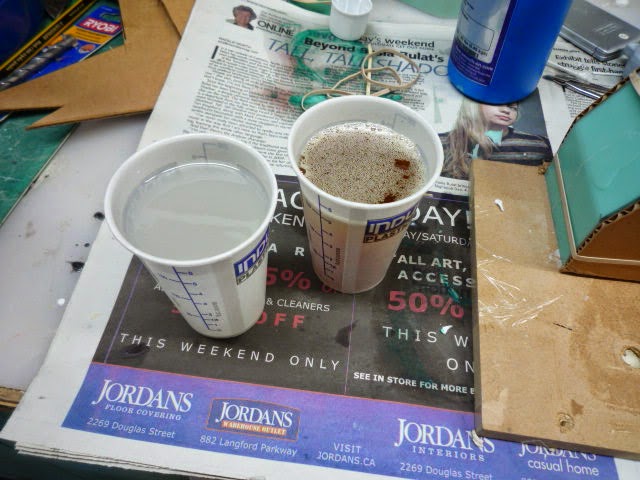

Ready for pouring. To estimate how much material to mix, I sometimes fill a container to the brim with water, then carefully dunk the object in. Then remove the object and measure how much water is needed to refill the container. Another way is to fill the mold halves with rice or some other small grain, then measure the amount.

Ready for pouring. To estimate how much material to mix, I sometimes fill a container to the brim with water, then carefully dunk the object in. Then remove the object and measure how much water is needed to refill the container. Another way is to fill the mold halves with rice or some other small grain, then measure the amount.

Measured amount of the smooth cast of your choice.

Measured amount of the smooth cast of your choice.

Into the pressure tank at 60lbs. If you don't have a pressure tank, just tap, bump or jostle the mold a bit to help the bubbles rise to the top.

Into the pressure tank at 60lbs. If you don't have a pressure tank, just tap, bump or jostle the mold a bit to help the bubbles rise to the top.

After a while, open the mold to reveal the cast. It's always tempting to open a mold too early, or handle a cast before it's fully set. I try to pour my casts before I go to bed, that way I can't do anything with it until I come home from work the next day.

After a while, open the mold to reveal the cast. It's always tempting to open a mold too early, or handle a cast before it's fully set. I try to pour my casts before I go to bed, that way I can't do anything with it until I come home from work the next day.

A bit of cleaning up to do is normal.

A bit of cleaning up to do is normal.

And a replica is made.

And a replica is made.

I'm going to go through the steps of molding and casting a prop part. In this case it's the gun grip for my DLT 19 blaster. I made the original part from MDF, then primed and sanded it smooth.

Plasticine you use is compatible with your molding material.

[

Smooth out the Plasticine as you go, and make sure you get a nice smooth seal around the object.

Plasticine.

Plasticine and any stray bits of rubber. The mold should be clean and smooth.

separate the two halves. You can remove the vents as you go, just be careful not to tear the mold.

separate the two halves and can remove the original object. Take some time to inspect the mold, look for any bits of rubber that have crept into places you don't want it, and trim it off.

Last edited by a moderator: