I have been wanting to do a 3D model with my CNC from pink foam for a while. I thought I would start with a simple model. Eve from WALL-E.

Eve does not have many parts, nor are there a lot of complicated lines or grooves to have to figure out.

I have not been able to find out how tall she really is, I guess about 5'. She won't be full scale due to the limits of the CNC. She will be about 3' tall when done. So let's say 3/5 scale.

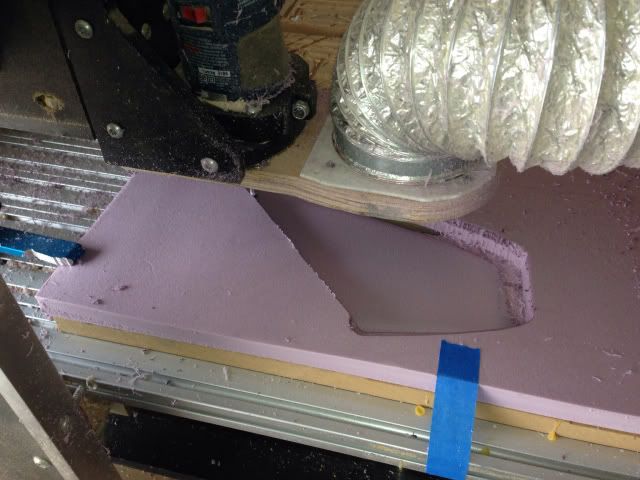

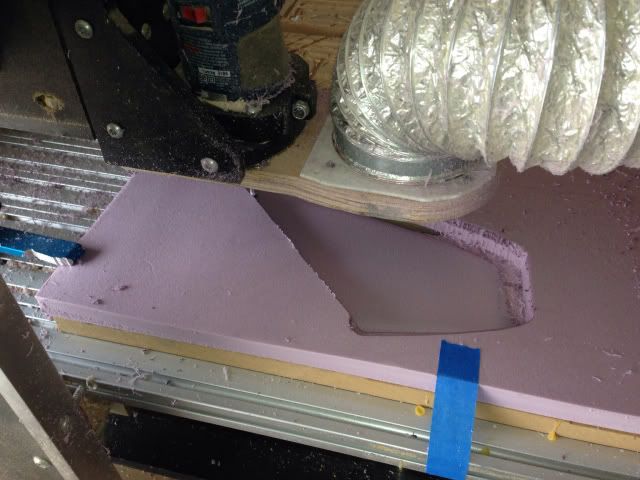

I am starting with the arms. They require the least amount of material. I had some readily available to get started.

The sheets are 3/4" thick. Each arm takes 4 layers.

The thin pieces tend to fall apart at the edges, but I can smooth that out later with joint compound or some other filler.

Both arms got glued up today and I will start working on her head next.

-Eric

Eve does not have many parts, nor are there a lot of complicated lines or grooves to have to figure out.

I have not been able to find out how tall she really is, I guess about 5'. She won't be full scale due to the limits of the CNC. She will be about 3' tall when done. So let's say 3/5 scale.

I am starting with the arms. They require the least amount of material. I had some readily available to get started.

The sheets are 3/4" thick. Each arm takes 4 layers.

The thin pieces tend to fall apart at the edges, but I can smooth that out later with joint compound or some other filler.

Both arms got glued up today and I will start working on her head next.

-Eric