Boba Debt

Master Member

EDIT- 5/29/2017

DENIX HAS UPDATED THIER MAUSER DESIGN

It would appear that Denix has made the following changes to their Mauser Replica

As part of my full build process I still find in necessary to clean up the knurling on the rear sight button and I fill the new engraved text in with JB Weld and sand it smooth.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

This thread only applies to the kits I recently offered but could be helpful to anyone building a DL-44 Blaster

This thread is open to discussion and all input is welcome but off topic questions might be ignored.

DENIX MAUSER DISASSEMBLY VIDEO - quick video that shows a detailed break down of the mauser. The next time I will talk as I go through the process.

DENIX BOLT INSTALLATION VIDEO - Video with audio that explains how to reinstall the bolt assembly

DENIX TRIGGER REMOVAL / INSTALLATION (VIDEO COMING SOON)

Removal-

1. Apply masking tape to the top of the receiver to prevent the loss of the spring one the pin is removed

2. Use a punch to remove the pin and drive the pin out from right to left

3. These are fairly loose so you can need very little pressure to remove it.

Installation-

I might mangle a mauser lower that the shop destroyed so I can create a tutorial for the mauser thread.

DENIX MAUSER – This Applies to accurized mausers without or with the ROTJ Machined Details:

REVERSE THE REAR SIGHT

The sight is made from 2 halves that are held together by 2 molded pins and friction force. When separating the halves, work both sides a little bit at a time or you could break off a pin.

APPLY ALUMINUM BLACK TO THE EXTRACTOR / BOLT

Aluminum Black is a liquid made by Birchwood Casey and it is available online or at most sports stores that sell gun supplies. It is a chemical and can burn the skin so use gloves when handling it. If used on large surfaces it can produce toxic odors so use it in a ventilated area.

Extractor:

Bolt Surface:

FIXING THE HAMMER KNURLING

The factory knurling on the hammer looks really bad so I fix it

Here is how I do it:

The top hammer knurling is from the factory and the bottom is after a modified hammer

WET SANDING PROCESS

Scott has more experience with this method so hopefully he will post any additional info that he may have

IMAGE OF WET SANDED MAUSER LOWER RECEIVER

FINISHING THE MAUSER

PAINT METHOD

DRY SPRAYING TECHNIQUE

Dry spraying creates a dull look to most paints.

This is the set up I use to paint the Mausers

Once the mauser is painted it will have a very matte look

I use paper towels to “buff” the paint and burnish it into the surface of the mauser

ALUMINUM BLACK METHOD

Scott has more experience with this method so hopefully he will post any additional info that he may have

FIXING THE GRIP SLIDE ISSUE

The wood grips provided by Denix seem to slide a little bit with factory hardware but they slide even more with the aftermarket BRASS GRIP HARDWARE that I install of provide.

I found a semi-permanent way to fix this but it is the last step once you have the blaster the way you want it.

Here is how I do it:

DENIX HAS UPDATED THIER MAUSER DESIGN

It would appear that Denix has made the following changes to their Mauser Replica

- The Rear Sght is now in a fixed positional all the way to the rear and the button is on the correct (right) side.

- The have added the following engraved text tot he left side above the trigger "DENIX MADE IN SPAIN"

As part of my full build process I still find in necessary to clean up the knurling on the rear sight button and I fill the new engraved text in with JB Weld and sand it smooth.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

This thread only applies to the kits I recently offered but could be helpful to anyone building a DL-44 Blaster

This thread is open to discussion and all input is welcome but off topic questions might be ignored.

DENIX MAUSER INFORMATION

DENIX MAUSER DISASSEMBLY VIDEO - quick video that shows a detailed break down of the mauser. The next time I will talk as I go through the process.

DENIX BOLT INSTALLATION VIDEO - Video with audio that explains how to reinstall the bolt assembly

DENIX TRIGGER REMOVAL / INSTALLATION (VIDEO COMING SOON)

Removal-

1. Apply masking tape to the top of the receiver to prevent the loss of the spring one the pin is removed

2. Use a punch to remove the pin and drive the pin out from right to left

3. These are fairly loose so you can need very little pressure to remove it.

Installation-

1. Set the trigger in place with the hammer catch in the aft position.

2. Hand start the pin from the left side until you see it just starting to protrude into the spring cavity

3. Use needle nose plies to set the spring in place

4. Use a punch to push down on the spring coil to push it into place while simultaneously pushing the pin more to the right with finger pressure.

5. Once you meet resistance on the right side use a punch to seat the pin into the right side hole.

2. Hand start the pin from the left side until you see it just starting to protrude into the spring cavity

3. Use needle nose plies to set the spring in place

4. Use a punch to push down on the spring coil to push it into place while simultaneously pushing the pin more to the right with finger pressure.

5. Once you meet resistance on the right side use a punch to seat the pin into the right side hole.

I might mangle a mauser lower that the shop destroyed so I can create a tutorial for the mauser thread.

DENIX MAUSER – This Applies to accurized mausers without or with the ROTJ Machined Details:

REVERSE THE REAR SIGHT

The sight is made from 2 halves that are held together by 2 molded pins and friction force. When separating the halves, work both sides a little bit at a time or you could break off a pin.

- Use a flat tip screwdriver to pry the rear sight apart by wiggling it into the seam between the two halves

- Move from one side to the other separating it a little bit at a time equally until it pops apart

- Reverse the sight so the molded release button points to the right as you hold the gun and press the two halves back together with pliers

- IF the friction is not enough to secure the sight, use a small dab of glue on each pin.

APPLY ALUMINUM BLACK TO THE EXTRACTOR / BOLT

Aluminum Black is a liquid made by Birchwood Casey and it is available online or at most sports stores that sell gun supplies. It is a chemical and can burn the skin so use gloves when handling it. If used on large surfaces it can produce toxic odors so use it in a ventilated area.

Extractor:

- I apply the Aluminum Black to the extractor with a q-tip lightly dipped in the liquid

- Even though the extractor is recessed, some liquid will get on the flat surface of the bolt

- Once the area has turned black I dry it with a paper towel

- Use a 400 grit sanding sponge to remove the black from the flat surface of the bolt by very lightly rubbing the flat surface

- Reapply Aluminum Black and re-sand as needed

Bolt Surface:

- I apply the Aluminum Black to the machined surface of the bolt with an acid brush

- Once the area has turned black I dry it with a paper towel

- I apply gun oil to the converted surface to blend the color

FIXING THE HAMMER KNURLING

The factory knurling on the hammer looks really bad so I fix it

Here is how I do it:

- I use a triangular jewelers file and carefully file each groove a little bit at a time until they are as straight as possible.

- It hard to tell if they look better until you apply Aluminum Black

- Sometimes I have to go back and file more after I darken it with Aluminum Black

The top hammer knurling is from the factory and the bottom is after a modified hammer

WET SANDING PROCESS

Scott has more experience with this method so hopefully he will post any additional info that he may have

- I use a 400 grit sanding pad soaked in alcohol to clean all of the mausers parts, this removes the oily residue and spot sands the parts simultaneously

- To get in the tight areas use a white scouring pad soaked in alcohol

- I also use a seriesof small files and sand paper to clean up any defect in the casting and I remove any obvious seem lines.

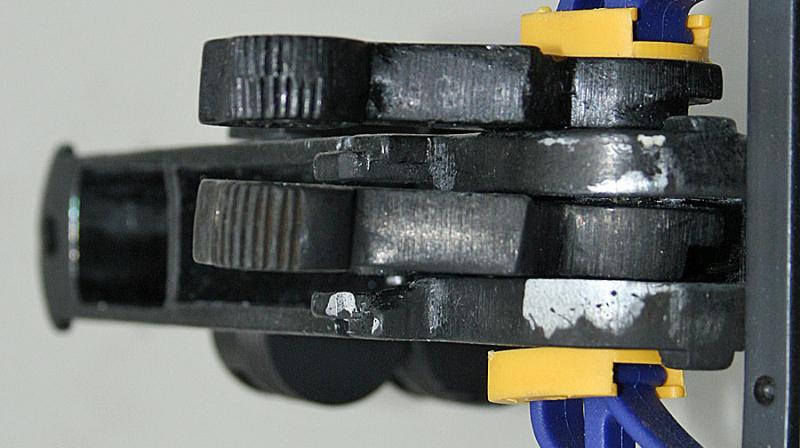

IMAGE OF WET SANDED MAUSER LOWER RECEIVER

FINISHING THE MAUSER

PAINT METHOD

DRY SPRAYING TECHNIQUE

Dry spraying creates a dull look to most paints.

- Spray the paint onto the item from about 12"-16" away

- Apply very light coats to allow the paint to mostly dry before it hits the item being painted

- Wipe down the item once it is dry to remove the "paint dust"

This is the set up I use to paint the Mausers

- I use Rustolium High Heat Paint and Testors Dullcoat

- I use a heat gun to bake the paint onto the Mauser

- Once I have applied a good base I "burnish" the paint into the surface by rubbing it with a paper towel

Once the mauser is painted it will have a very matte look

I use paper towels to “buff” the paint and burnish it into the surface of the mauser

ALUMINUM BLACK METHOD

Scott has more experience with this method so hopefully he will post any additional info that he may have

- I apply the Aluminum Black to the machined surfaces with an acid brush and to any area that needs to be blackened

- Once everything has turned black I dry everything with a paper towel

- I repeat this process until the desired look is accomplished

- I apply gun oil to the converted surface to blend the color and protect the finish

FIXING THE GRIP SLIDE ISSUE

The wood grips provided by Denix seem to slide a little bit with factory hardware but they slide even more with the aftermarket BRASS GRIP HARDWARE that I install of provide.

I found a semi-permanent way to fix this but it is the last step once you have the blaster the way you want it.

Here is how I do it:

- Attach the grip to insure that they are correctly aligned

- Remove the left grip and while holding the right grip in place apply 5 Minute Epoxy to the areas indicated in red

- Reinstall the left grip and align the grips

- Set aside for 1 hour to insure that the epoxy has cured

- It is possible to remove the grip by using a Dremel to remove most f the epoxy but this is not a simple task

Last edited by a moderator: