Another Captain America project is under way and this one has a bit of a twist. It's being made so that it's convertible - the torso can be swapped out and the chest stripes can be removed so the costume can be work as either the "classic" Cap or the Commander Rogers "stealth suit" version. Here's the concept rendering for the top.

The suit will also have the harness and belt. The pants will be modeled after basic BDU pants but will be made in the same blue Cordura as the top. I really worked with the client on the concept and design for this suit. He wanted something that had the feel of the movies but was unique and that could be worn as two different costumes. I thought his ideas were brilliant and I was very excited to work on the project.

To get started, I had the client (who is out of state from me) fill out his measurement card and send it back. It just so happens that he was almost exactly the same size as a friend of mine who was at the studio quite a bit while we worked on a costume for him. So, I decided to kidnap him one afternoon and make a duct tape dummy of his torso and one arm to use for drafting the patterns.

He looks thrilled, right? Once I cut it off, I used the side without the arm to make the torso pattern and reserved the side with the arm for the upper jacket.

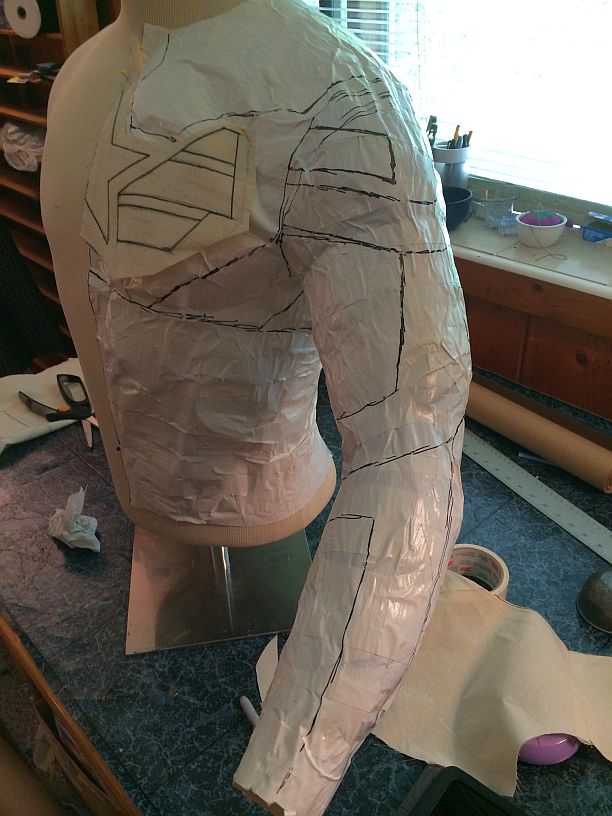

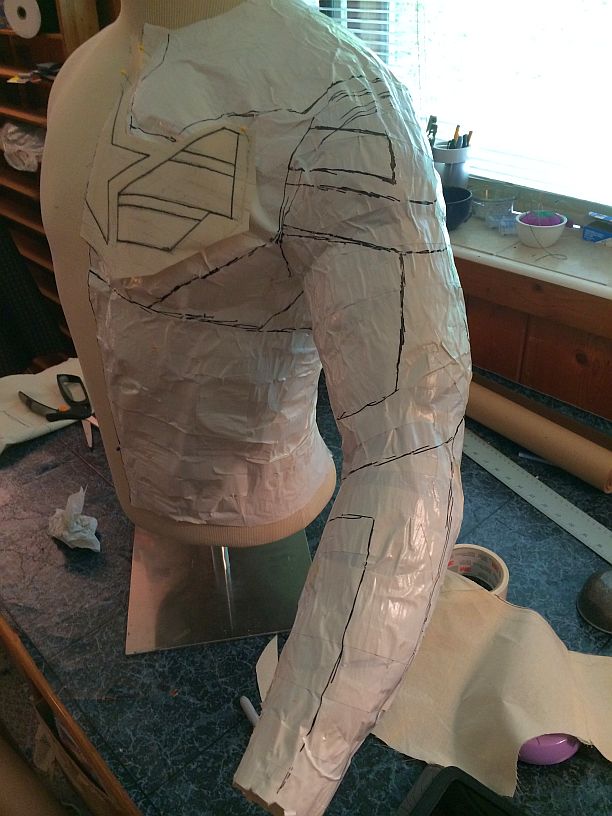

I pinned the entire side to a form and used a sharpie to map out the seam lines for the jacket.

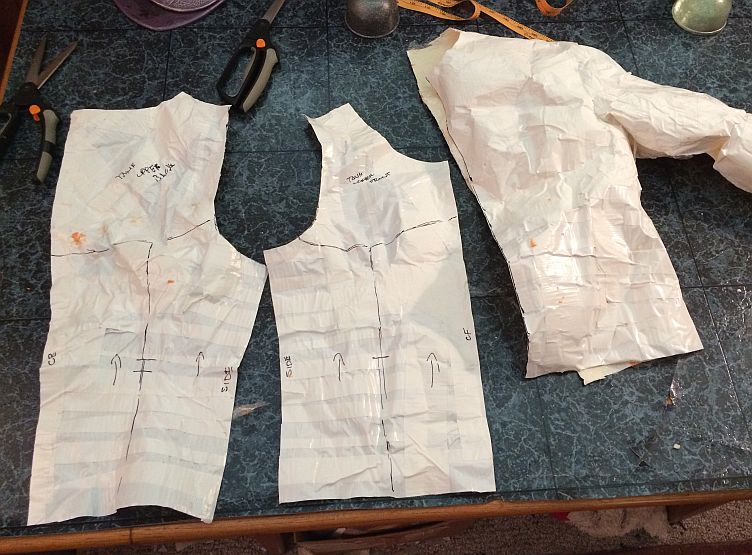

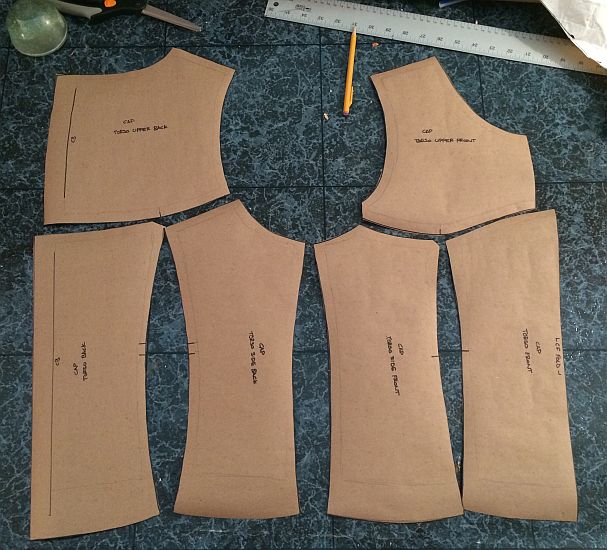

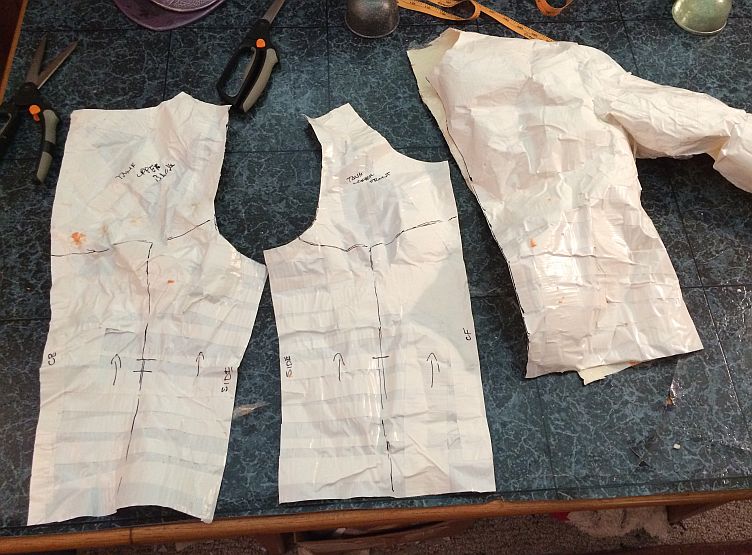

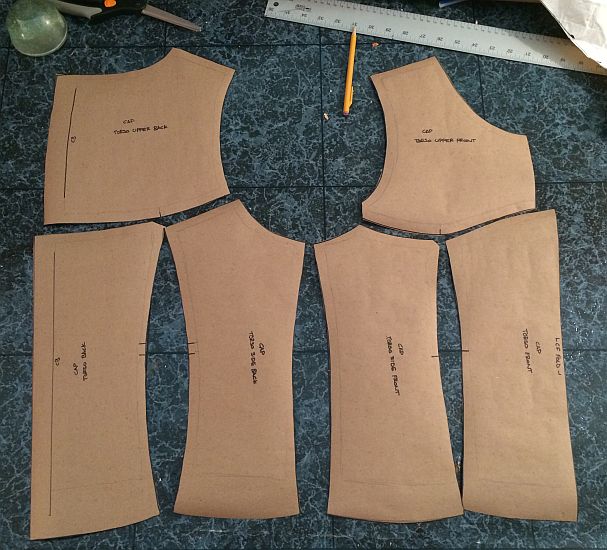

After cutting apart all the duct tape pieces, cleaning up the lines and tracing it all out on paper, I had patterns for my two upper body pieces.

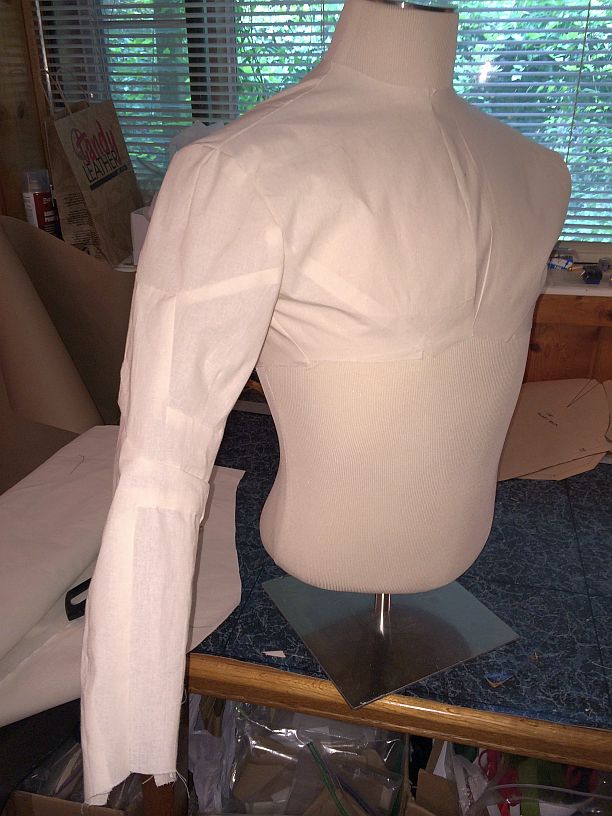

The next step was to make a mock up to send to the client for fitting. I had some remnants of Cordura, jumbo spandex and headliner foam from other projects, so I raided those to create the fitting model. The upper picture is both pieces as they will fit together and the lower is just the torso. As I mentioned before, there will be two different torso pieces - one that's all blue for the "stealth" version and one that's red and silver for the "classic. The torso will fit like a tank top with athletic mesh on the top under the jacket to keep it as cool and breathable as possible.

Once the client tried on the fitting pieces, sent me pics and we discussed alterations, the real construction could begin. The costume is being made in 500 Denier Cordura with stretch accents made of jumbo spandex. There are also areas of the costume that will be fitted with headliner foam to add structure and support and all of the non-stretch areas are being lined with cotton for comfort and to absorb moisture.

I began with the sleeves. I had to cut apart the shoulder bells to design in the stripes. I'm using an upholstery weight vinyl that has a stainless steel type finish for all the stripes. I built the blue and silver bells and then made the foam inner layer.

Here's a pic of the upper arm with the shoulder attached. When using the jumbo spandex on costumes like this one, I like to use the wrong side of the fabric. It has a nice texture that reads like a really cool knit rather than the bright sheen of the spandex and it goes really nicely with the navy blue Cordura.

And here are the sleeves completed.

Next: construction begins on the rest of the jacket. Stay tuned...

The suit will also have the harness and belt. The pants will be modeled after basic BDU pants but will be made in the same blue Cordura as the top. I really worked with the client on the concept and design for this suit. He wanted something that had the feel of the movies but was unique and that could be worn as two different costumes. I thought his ideas were brilliant and I was very excited to work on the project.

To get started, I had the client (who is out of state from me) fill out his measurement card and send it back. It just so happens that he was almost exactly the same size as a friend of mine who was at the studio quite a bit while we worked on a costume for him. So, I decided to kidnap him one afternoon and make a duct tape dummy of his torso and one arm to use for drafting the patterns.

He looks thrilled, right? Once I cut it off, I used the side without the arm to make the torso pattern and reserved the side with the arm for the upper jacket.

I pinned the entire side to a form and used a sharpie to map out the seam lines for the jacket.

After cutting apart all the duct tape pieces, cleaning up the lines and tracing it all out on paper, I had patterns for my two upper body pieces.

The next step was to make a mock up to send to the client for fitting. I had some remnants of Cordura, jumbo spandex and headliner foam from other projects, so I raided those to create the fitting model. The upper picture is both pieces as they will fit together and the lower is just the torso. As I mentioned before, there will be two different torso pieces - one that's all blue for the "stealth" version and one that's red and silver for the "classic. The torso will fit like a tank top with athletic mesh on the top under the jacket to keep it as cool and breathable as possible.

Once the client tried on the fitting pieces, sent me pics and we discussed alterations, the real construction could begin. The costume is being made in 500 Denier Cordura with stretch accents made of jumbo spandex. There are also areas of the costume that will be fitted with headliner foam to add structure and support and all of the non-stretch areas are being lined with cotton for comfort and to absorb moisture.

I began with the sleeves. I had to cut apart the shoulder bells to design in the stripes. I'm using an upholstery weight vinyl that has a stainless steel type finish for all the stripes. I built the blue and silver bells and then made the foam inner layer.

Here's a pic of the upper arm with the shoulder attached. When using the jumbo spandex on costumes like this one, I like to use the wrong side of the fabric. It has a nice texture that reads like a really cool knit rather than the bright sheen of the spandex and it goes really nicely with the navy blue Cordura.

And here are the sleeves completed.

Next: construction begins on the rest of the jacket. Stay tuned...

Last edited by a moderator: