no problem..

I too said its a bit pricey... (could get two more mini's!)

but the shipping wait from China can be a 'killer' for motivation too! lol.

the good thing is, once you have a nice foundation of tools (programmers, Arduino boards)..

future projects wont cost as much..

I've said it before.. and I'll say it again..

I recommend EVERYONE get an Arduino Duemilanove or Uno (not SMD chip version)..... EVEN IF THEY PLAN ON USING A NANO OR PRO-MINI in their end projects!

They are great for testing components with breadboard set-ups to ensure your logic/ideas are sound.. practice with components that are new to you..

and you can use your Duemilanove/Uno as a programmer to FLASH bootloaders or upload sketches to your custom boards or blank chips if you want.

Matter of fact that has been the ONLY way I have ever flashed a bootloader onto my chips..

Arduino board ad Arduino IDE as ISP..

ICSP = used to flash bootder

FTDI = used to upload sketches..

more boards (even blank chips now a days) come with the bootloader already flased on the chip.. so most people dont worry about that.. (mostly for new or blank chips or more advanced people use diff bootloaders for different things)

Just recently.. I have been BY-PASSING the bootloader all together and using an ICSP cable to upload my sketches.. (makes very fast boot times and more space left on chip)..

to be clear this are on PURPOSE built boards, not really an Arduino..

example:

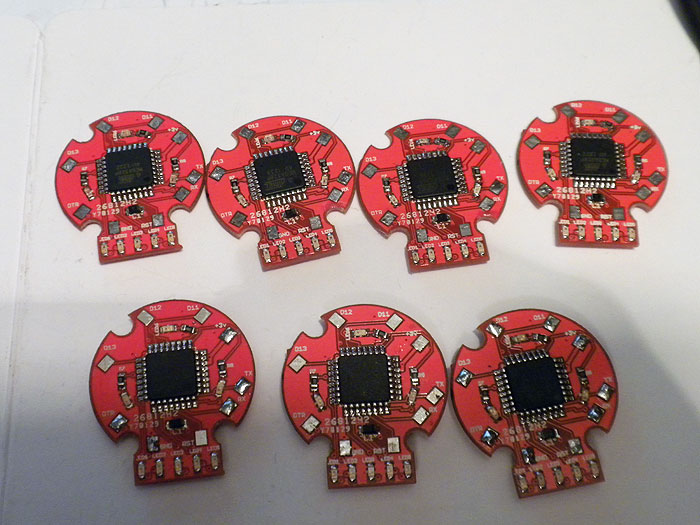

these are 'Arduinos'... for lack of a better term..

they are the same minimal Arduino circuit design...

but instead of breaking out all I/O pins.. I only broke out the pins that are used for this project (just some leds and some audio)..

I flashed these with Arduino bootloader like I would any new/blank chip.....

and used the FTDI cable (linked to above) to upload my code/sketches..

done deal...

however.. learning more and getting a new/special ICSP cable..

I learned I can not use a bootloader and upload directly to the chip... (kinda making it NOT an Arduino anymore as there is no bootloader and the IDE can no longer be used to upload sketches)

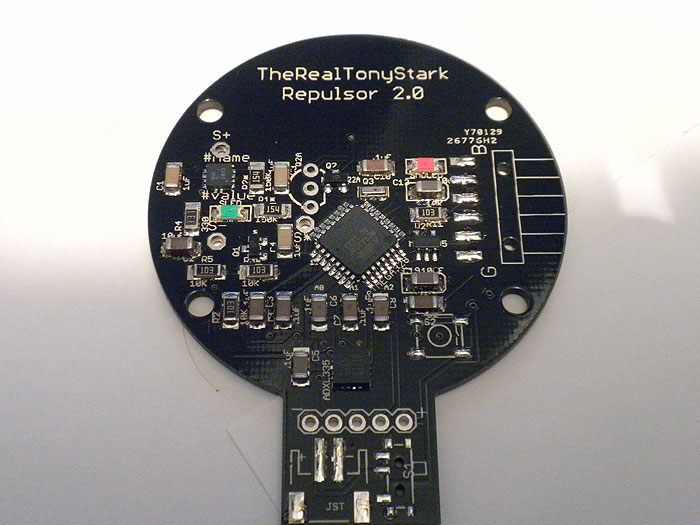

looking at this project for example:

it had some obstacles to overcome..

initially there was no ICSP header on the board? ow are we going to get a bootloader on there then! (yikes!)

well purchased a cable from Hobby King that does ICSP on the SMD chip directly.. (meaning there doesnt need to be a header or pads broken out.. which helps when you have to overcome 'mistakes' like this!)

if you look at the irght side of the pcb..you'll see the (missing) header section..

this is the FTDI headers.. where I would normally just hook up the FTDI cable and upload new sketches..

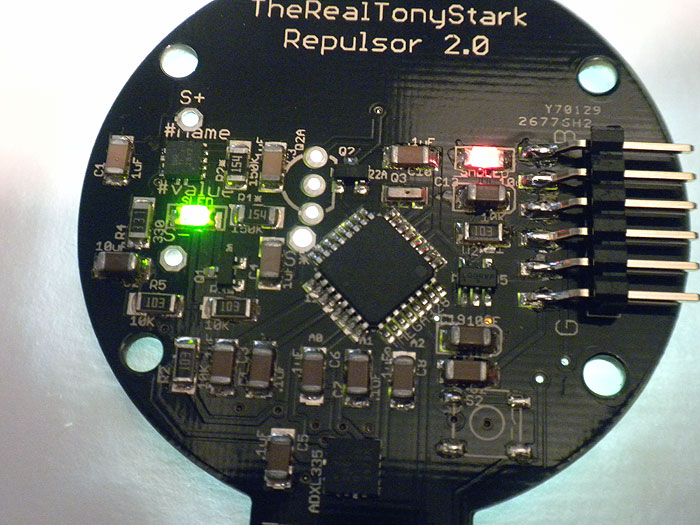

better pic with header installed:

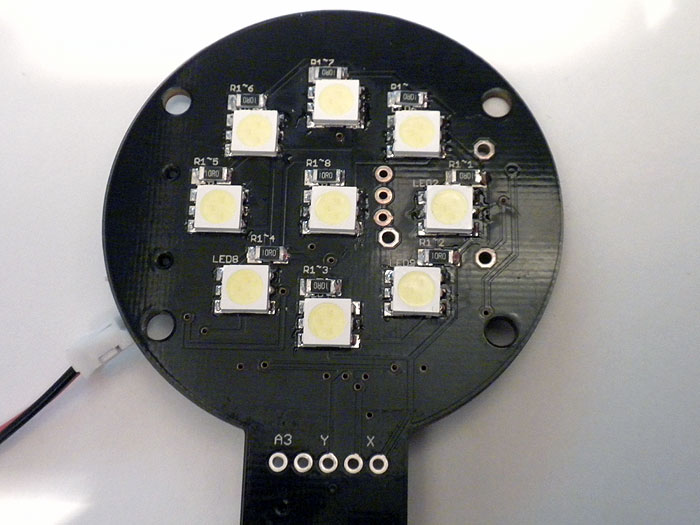

led side:

this is using more or less the same principle as we outlined here..

a bunch of leds... triggered/toggled by a transistor..

this just happens to be a custom board with all that junk built in.. instead of piecing it together with an Arduino..