Thanks!

Yeah, the filming model was only about 5' 4" long (and a little more than 30" wide). The model was built at the same scale as the larger Jefferies' plans (which were originally on a 24" x 36" sheet). Jefferies packed a ton of information into a single sheet by having the front half of the primary hull drawn over the back half (which also gives you the elements needed for the front view of the primary hull).

The excuse that Paramount gave for starting over with a new model was that the Phase II Enterprise was too small for the big screen. This, obviously, wasn't true because the Reliant was the small approximate scale and looked just fine. The real reason seems to have been wanting to give Magicam (owned by Paramount) the chance to get a big budget model credit under their belts.

The best way to see the size difference between the TMP Enterprise model and the Phase II Enterprise model is by looking at one of the Planet Hollywood models in it's new home inside the TMP Space Dock (

here).

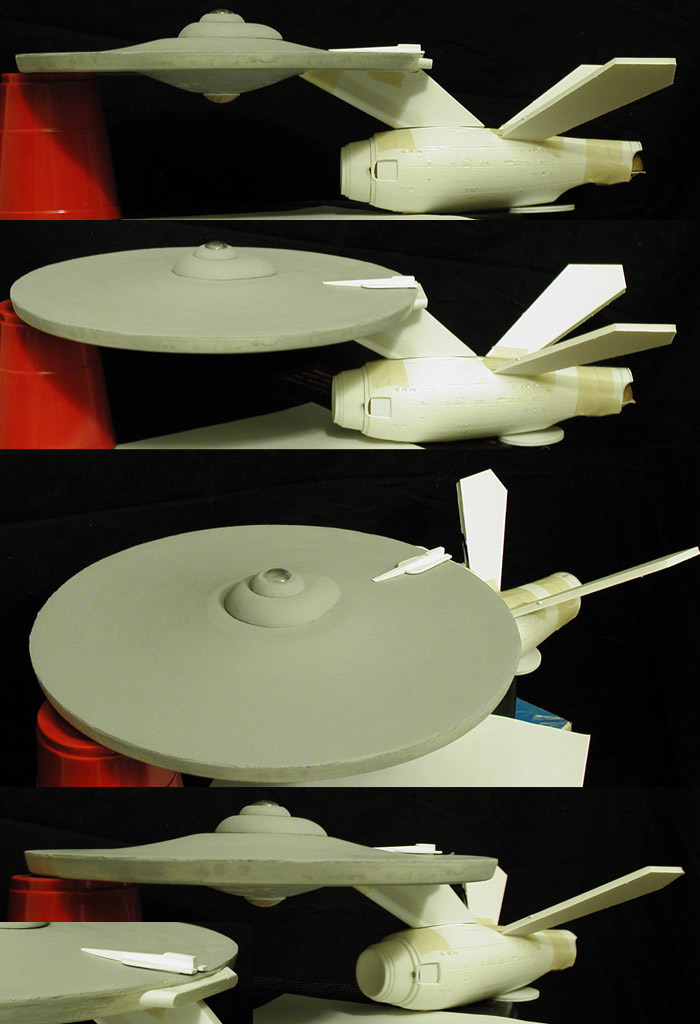

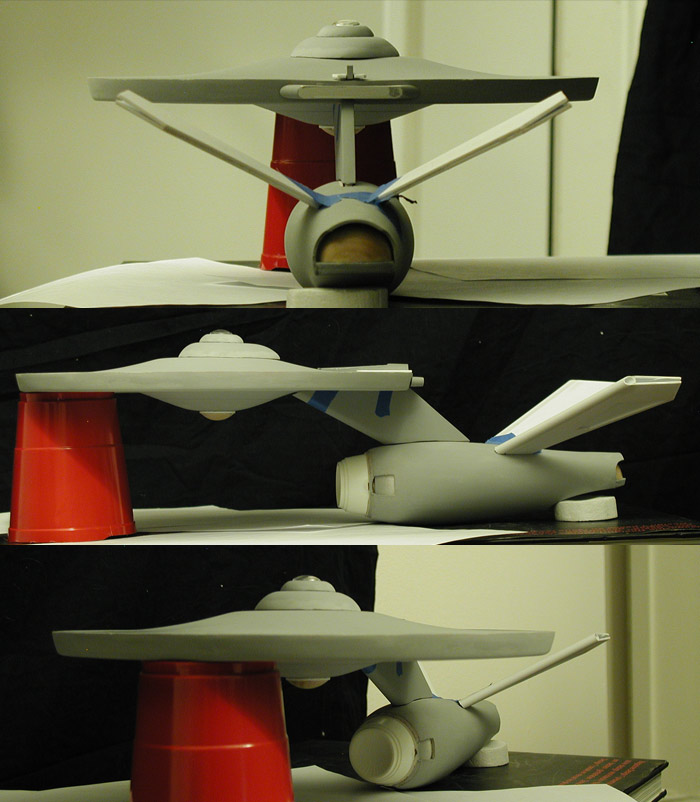

Quick progress report...

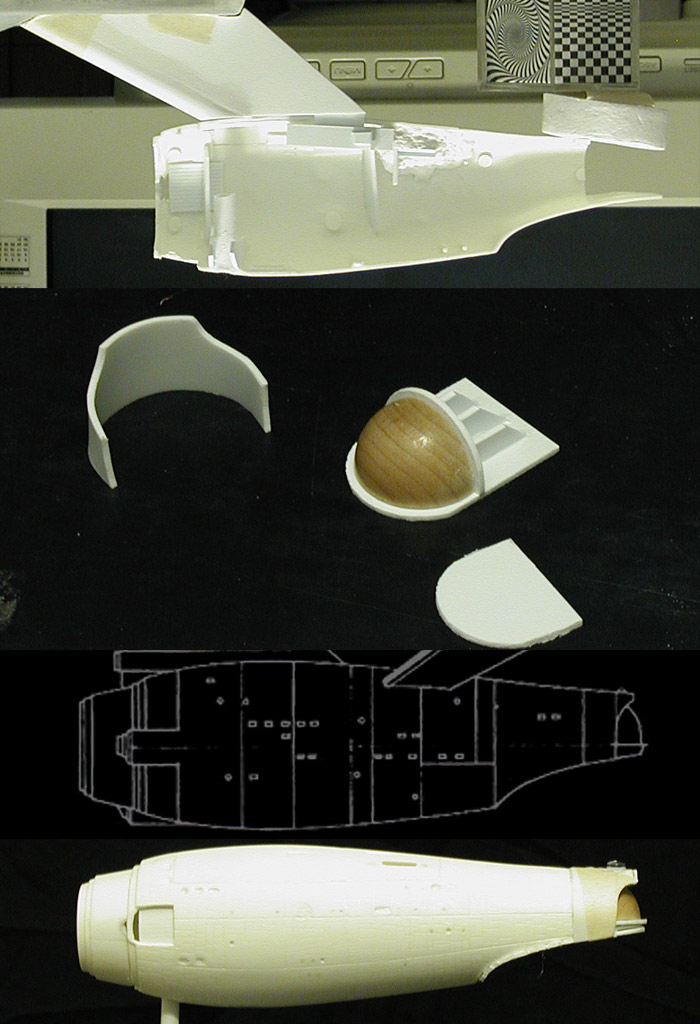

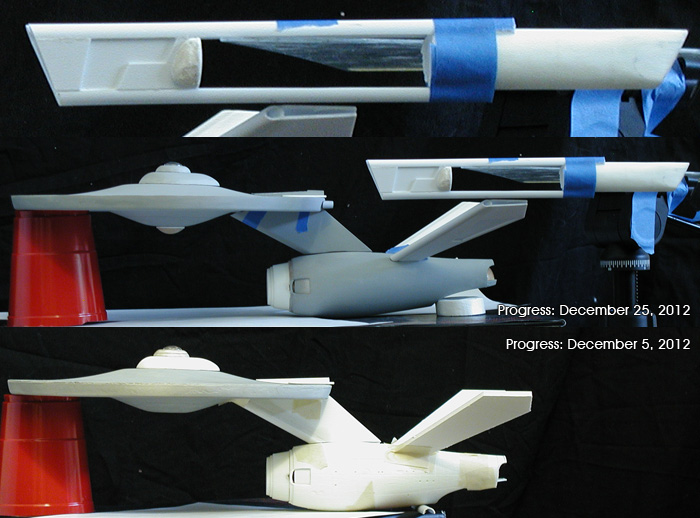

So this is a good example of why I'm building a study model before attempting a full set of plans of the Phase II Enterprise. Similar to how the Price/Loos model didn't follow Jefferies' plans on the dorsal pylon, the model doesn't seem to have followed the plans for the nacelle support pylons either. Oddly enough, the model's supports are more like the TMP studio model's in overall geometry.

I'll draw up some comparison diagrams of what Jefferies' had designed with what Price/Loos built (including some photos) when I get the chance. But what started out as a project to do one set of plans is definitely going to end up as two distinct sets of plans of the Phase II Enterprise.

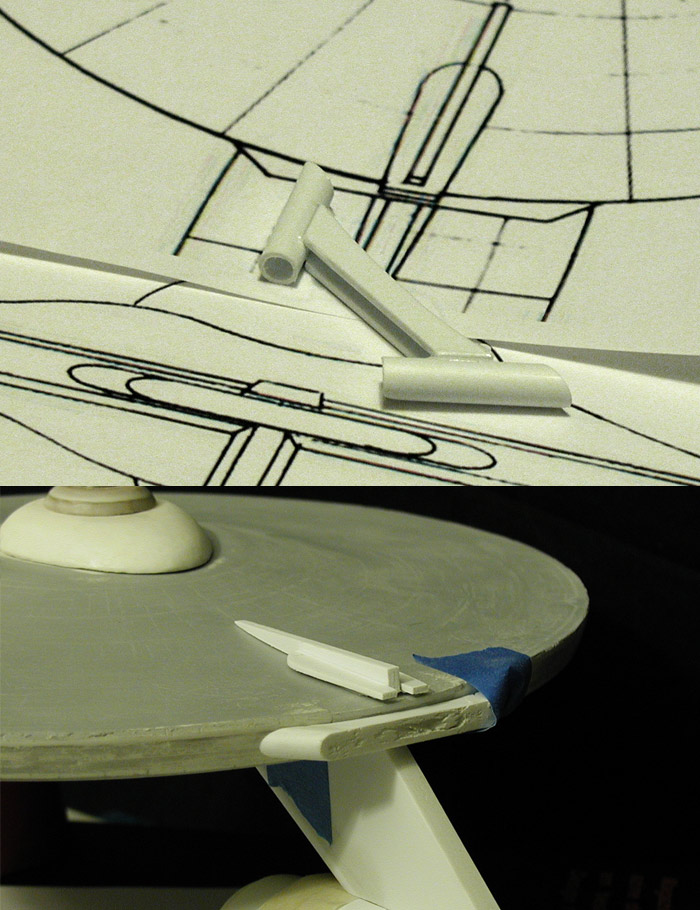

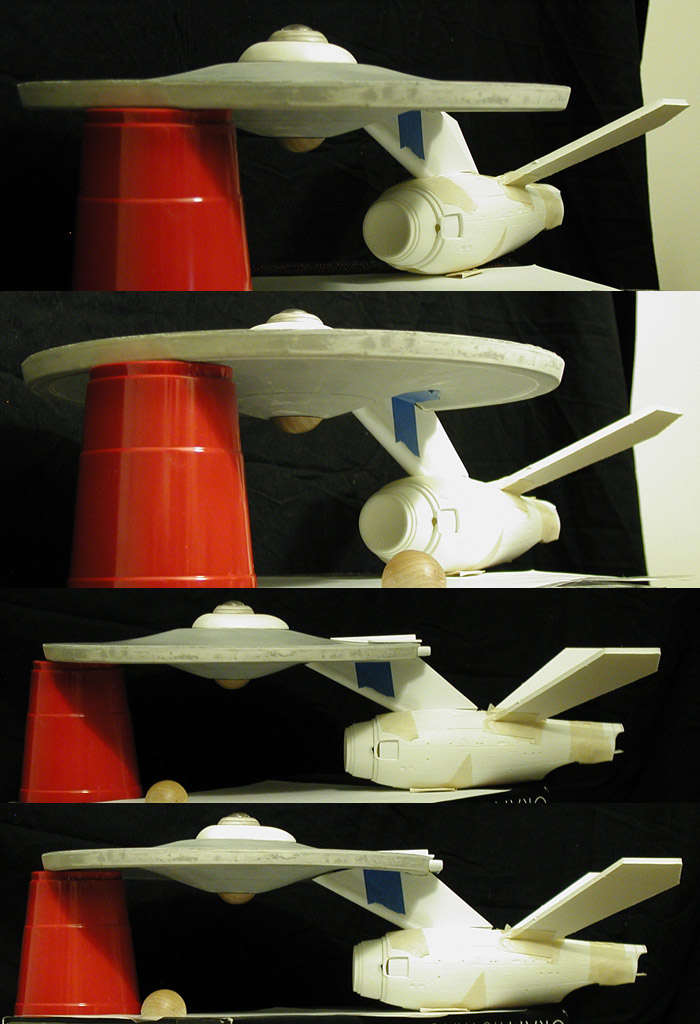

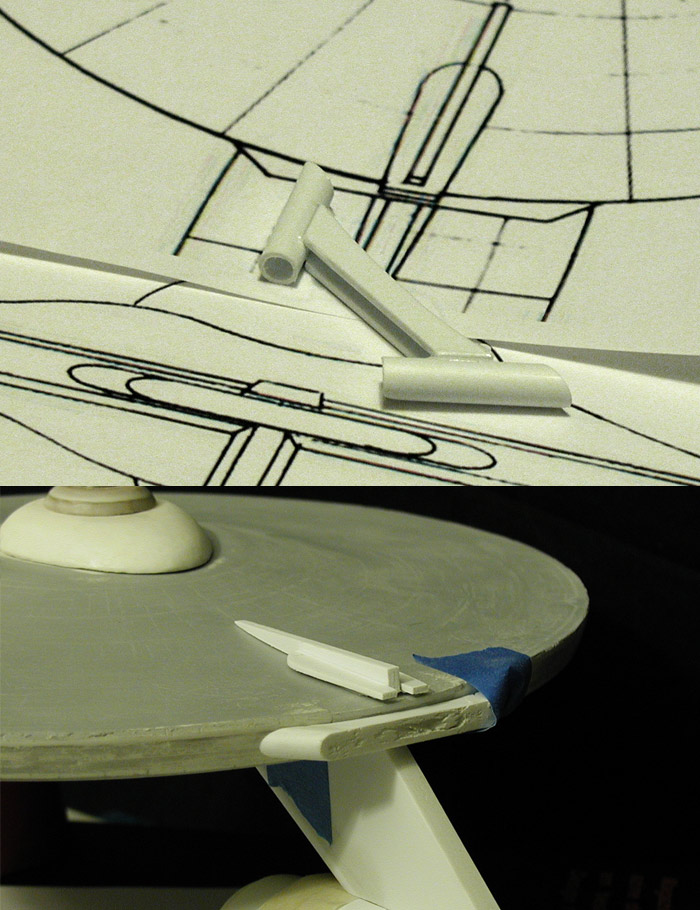

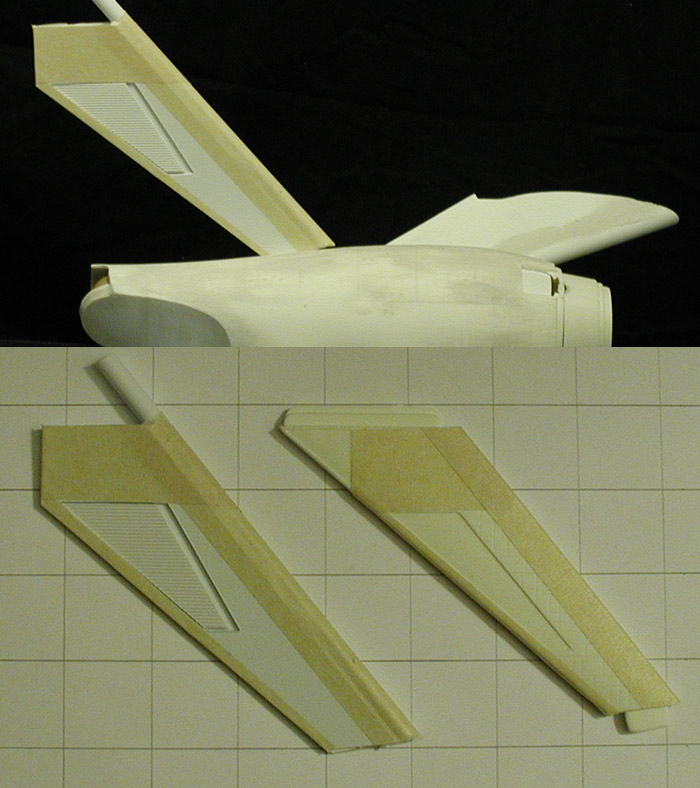

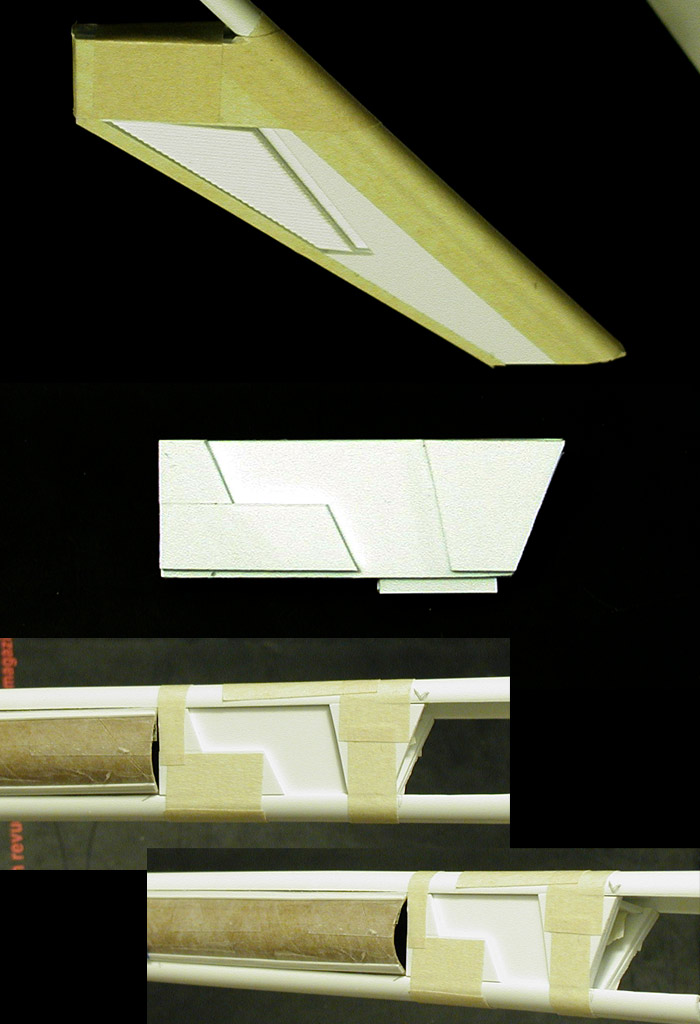

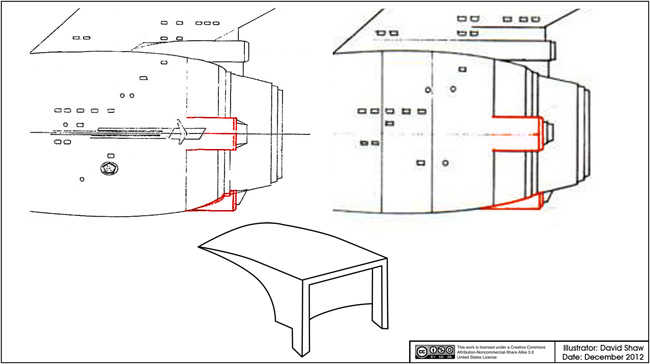

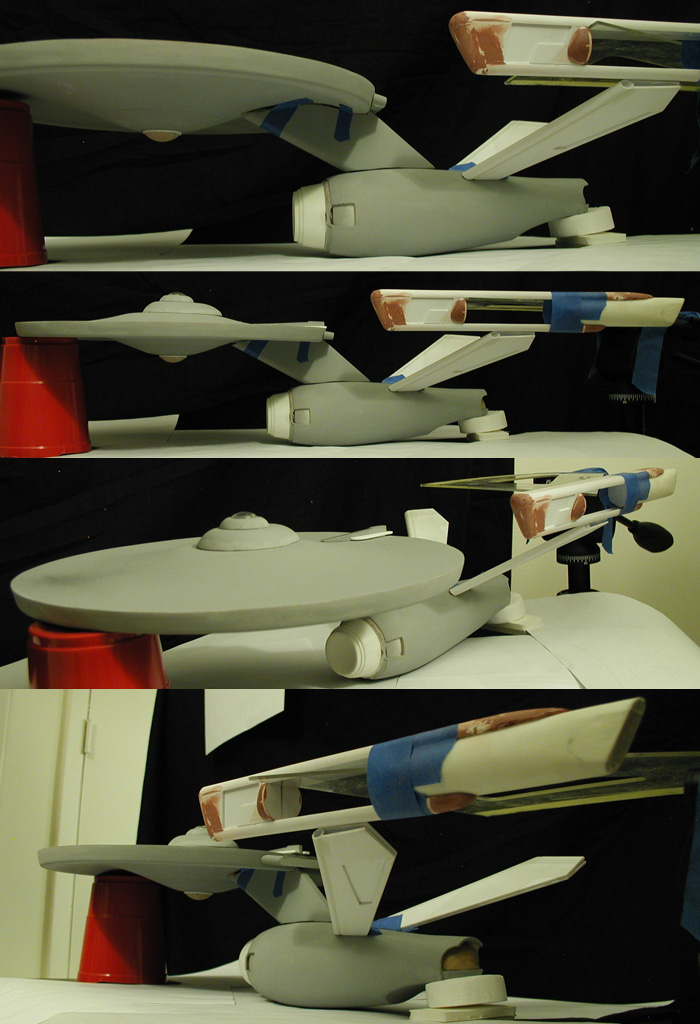

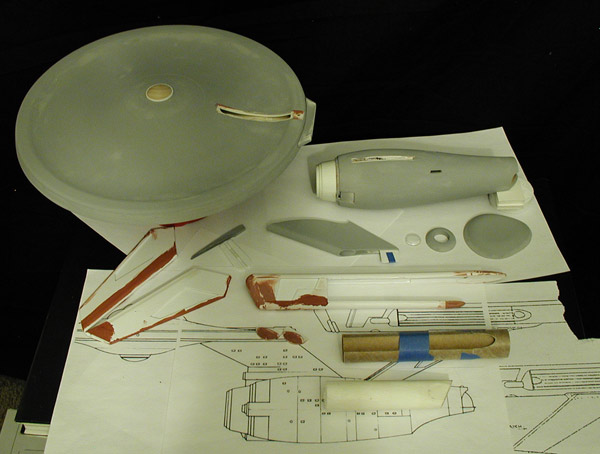

I taped together the parts for one of the supports (with a quickly cut stand-in grill, the final grills most likely won't be made until I'm ready to paint the model) to see how they worked. I've ended up with the shapes I was going for, so I'm pretty confident that I'm on the right track with these. I won't finalize the top or bottom edges until after I have the primary hull, dorsal and secondary hull together as a single piece (so I can make adjustments in the overall alignment of the model).

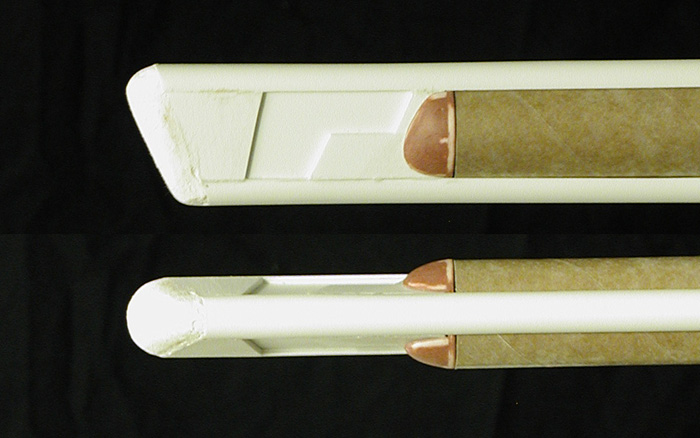

Here is how the taped together support looks (and a comparison with the original kit's support)...

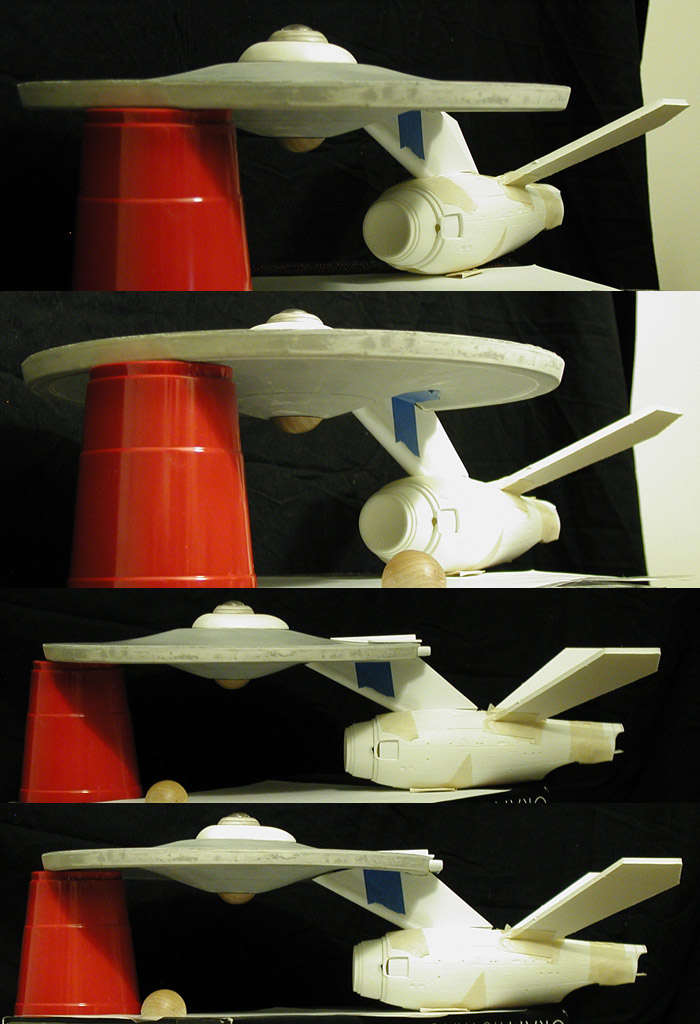

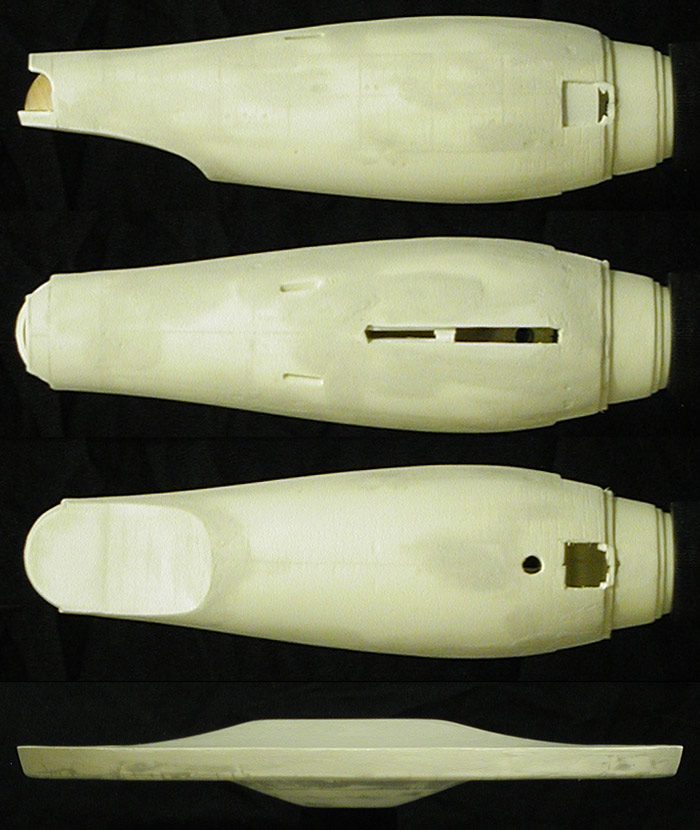

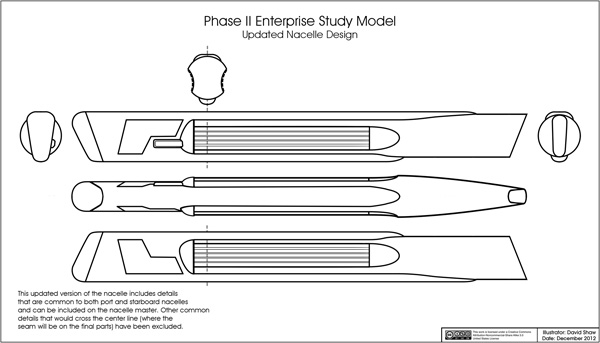

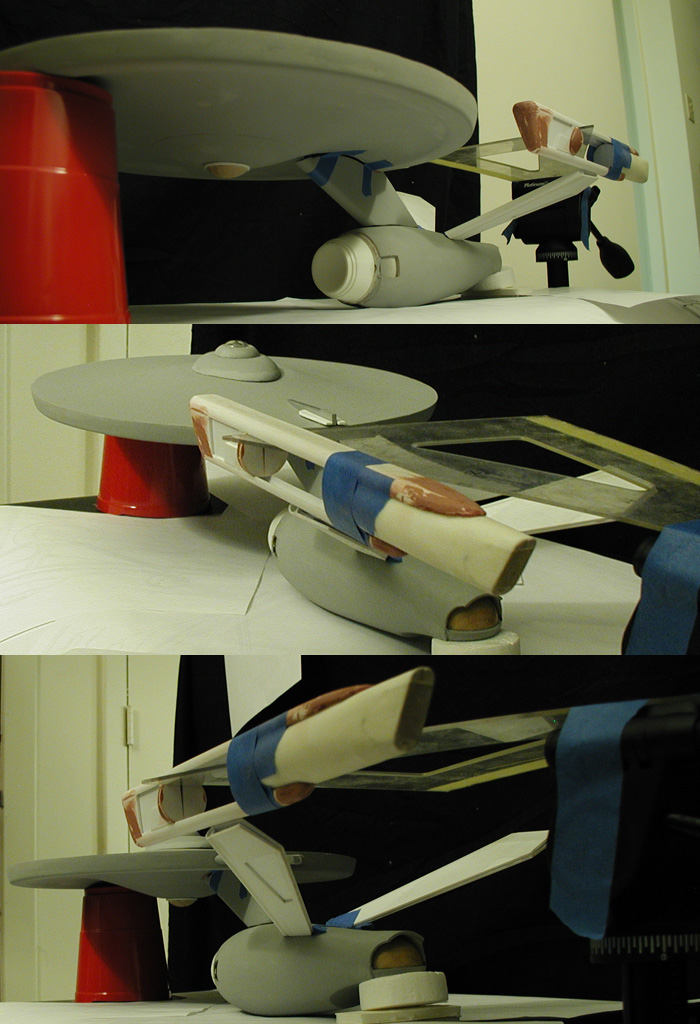

I spent most of this week working on the front half of the nacelle master. I cut out the many pieces that make up the front third and glued them together. I then cut some styrene tubing in half to make the lengthwise contours of the top and bottom of the nacelle. Before I cut those to their final length I tested their fit with the front third section and a stand-in section of cardboard tubing (covered in packing tape so I can sculpt the ends of the top and bottom sections later on without them sticking to the tubing) to make sure everything was coming together correctly.

Below is another shot of the test assembled nacelle pylon support (this time shown at the approximate angle you'd see it at from the side), the front third section of the nacelle by itself and a couple shots of the test assembly of the front half of the nacelle master.

I still need to get to the center section with the grill work. Once that is done, I need to graft it to the rear section of the nacelle I made earlier to complete the back half of the nacelle master. It is slow going, but I think what I'll end up with is a really nice looking nacelle which (hopefully) will yield two nice nacelles for the model.